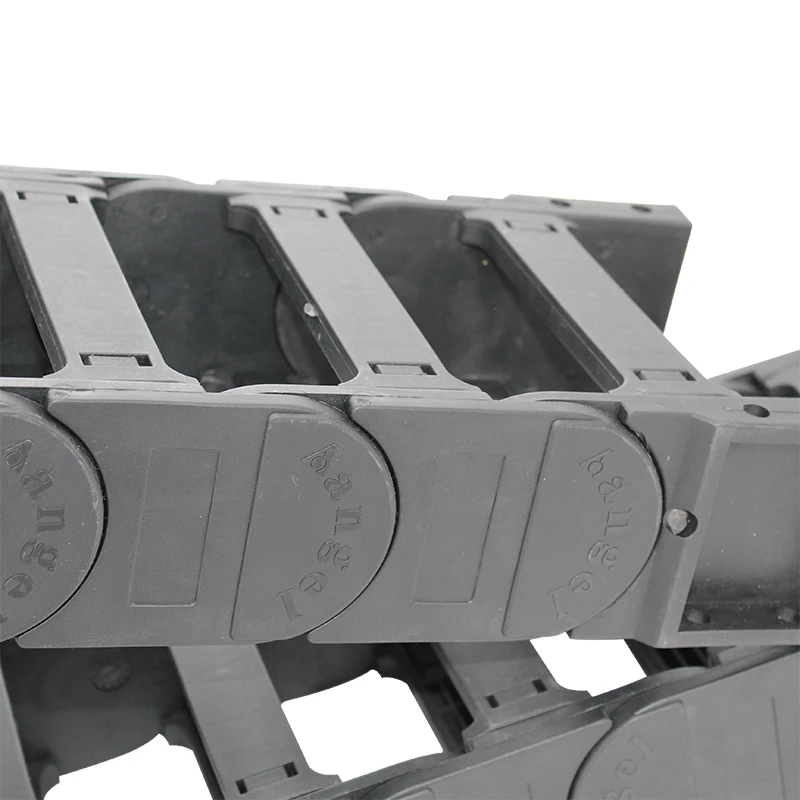

nylon flexible wire loom corrugated bellow conduit hose pipe

Corrugated plastic electrical conduit has rapidly become a critical component in modern electrical systems, offering an unparalleled blend of flexibility, durability, and efficiency. Drawing from extensive industry experience and authoritative insights, this article unveils the indispensable advantages of incorporating corrugated plastic conduits into electrical designs, underlining their superior performance in various applications.

Expert users of corrugated plastic conduits appreciate the product’s versatility across a gamut of applications, from residential wiring to complex industrial installations. The non-conductive nature of plastic ensures there is no risk of electrical conductivity, reducing potential hazards when bundled with power, data, and communication cables. This safety aspect further amplifies the credibility and trust that users have in these conduits as a first-line defense in protecting both infrastructure and personnel. Trustworthiness is additionally underscored by compliance with pertinent electrical standards and regulations. Corrugated plastic conduits are rigorously tested and certified to meet stringent safety and performance benchmarks, providing assurance of reliability once installed. Manufacturers uphold this trust by consistently innovating and enhancing their product offerings in response to evolving market needs and technological advancements. In summary, corrugated plastic electrical conduits exemplify a forward-thinking approach in the field of electrical engineering, where their remarkable attributes culminate in a product that is as reliable as it is versatile. For decision-makers aiming to implement cutting-edge solutions with assured longevity, corrugated plastic conduits prove to be the ultimate choice, marrying practical benefits with the high standards of modern safety requirements.

Expert users of corrugated plastic conduits appreciate the product’s versatility across a gamut of applications, from residential wiring to complex industrial installations. The non-conductive nature of plastic ensures there is no risk of electrical conductivity, reducing potential hazards when bundled with power, data, and communication cables. This safety aspect further amplifies the credibility and trust that users have in these conduits as a first-line defense in protecting both infrastructure and personnel. Trustworthiness is additionally underscored by compliance with pertinent electrical standards and regulations. Corrugated plastic conduits are rigorously tested and certified to meet stringent safety and performance benchmarks, providing assurance of reliability once installed. Manufacturers uphold this trust by consistently innovating and enhancing their product offerings in response to evolving market needs and technological advancements. In summary, corrugated plastic electrical conduits exemplify a forward-thinking approach in the field of electrical engineering, where their remarkable attributes culminate in a product that is as reliable as it is versatile. For decision-makers aiming to implement cutting-edge solutions with assured longevity, corrugated plastic conduits prove to be the ultimate choice, marrying practical benefits with the high standards of modern safety requirements.