Understanding the Mechanics and Benefits of Synchronous Belt Drive Systems in Engineering

Understanding Synchronous Belt Drive A Comprehensive Overview

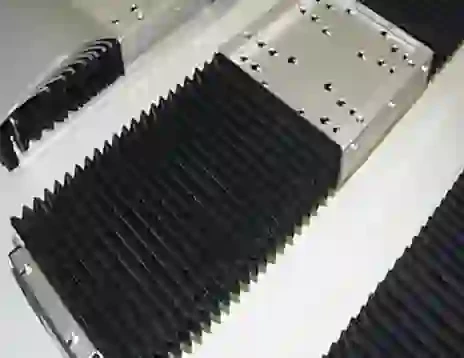

Synchronous belt drives are mechanical systems widely used in various applications for power transmission and motion control. They provide a reliable and efficient means of transmitting power between rotating shafts while maintaining precise timing and synchronization. Unlike traditional belt drives, which may slip or lose synchronization, synchronous belt drives utilize teeth on both the belt and the pulleys to ensure a positive engagement. This article delves into the key components, advantages, and applications of synchronous belt drives.

Key Components

1. Synchronous Belt The synchronous belt, often made from neoprene or other durable materials, is designed with teeth that mesh with corresponding grooves on the pulleys. This design minimizes the risk of slippage and allows for accurate movement. Synchronous belts come in various sizes and tooth profiles to fit different applications.

2. Pulleys Pulleys in a synchronous belt drive system have teeth that match those on the belt. These pulleys can either be fixed or variable diameter types, depending on the desired speed and torque characteristics of the system. They are typically made from materials like aluminum or polyamide to achieve a balance between strength and weight.

3. Tensioning System Proper tensioning of the synchronous belt is crucial for optimal performance. An adequate tensioning system, which may include adjustable idler pulleys or tensioners, ensures that the belt maintains appropriate pressure against the pulleys, preventing slippage or excessive wear.

Advantages of Synchronous Belt Drives

1. High Efficiency Synchronous belt drives are known for their high efficiency in power transmission, often exceeding 95%. This efficiency arises from minimal energy loss due to slippage or friction, making them an ideal choice for applications requiring consistent performance.

2. Precise Timing The positive engagement of the belt’s teeth with the pulleys allows for precise timing in motion transfer. This feature is particularly important in applications like robotics, CNC machines, and automotive timing systems where accurate synchronization of components is key to performance.

3. Low Maintenance Compared to other mechanical drives, synchronous belt drives require less maintenance. Their enclosed nature protects against dirt and debris, which can cause wear and tear in other systems. Regular inspections and proper tension adjustments are typically sufficient to keep a synchronous belt drive operating smoothly.

synchronous belt drive

4. Reduced Noise Levels Synchronous belt drives operate more quietly compared to chain drives or gear systems. The smooth engagement of the belt eliminates the thumping and rattling noises often associated with other forms of mechanical drives.

5. Compact Design Due to the lightweight nature of the synchronous belt and its pulleys, these systems can be designed to be compact. This is advantageous in modern machinery where space optimization is critical.

Applications

Synchronous belt drives find applications across a variety of industries, reflecting their versatility and reliability

- Automotive Industry They are primarily used for timing belts in engines, ensuring that the camshaft and crankshaft remain in sync for optimal engine function. - Manufacturing Synchronous belt drives are common in conveyor systems, CNC machines, and automated manufacturing equipment where precise movements are required.

- Home Appliances Devices such as washing machines and food processors often utilize synchronous belt drives for reliable performance.

- Robotics In robotics, precision movement is crucial. Synchronous belt drives allow for accurate positioning and speed control, essential for robotic arms and automated systems.

Conclusion

Synchronous belt drives offer a unique blend of efficiency, precision, and low maintenance, making them an integral component in various mechanical systems across multiple industries. As technology continues to advance, the development of synchronous belt drive systems will likely evolve, incorporating new materials and designs to meet the changing demands of modern engineering. Whether in automotive applications, manufacturing systems, or everyday appliances, synchronous belt drives remain a cornerstone of reliable mechanical power transmission.