Durable Telescopic Ball Screw Covers for Machine Protection

The Indispensable Role of Advanced Machine Protection in Industrial Automation

In the demanding landscape of modern industrial automation, the precision, reliability, and longevity of machinery are paramount. Critical components like ball screws, linear guides, and hydraulic cylinders are often exposed to harsh operating environments, including abrasive dust, metal chips, corrosive coolants, and intense heat. This exposure can lead to premature wear, reduced accuracy, and costly downtime. Protecting these vital elements is not merely an option but a strategic imperative for operational continuity and efficiency. Advanced machine protection solutions are engineered to shield these sensitive parts, extending their operational life and maintaining high performance standards. Among these solutions, the telescopic ball screw covers stand out as a highly effective and robust choice, specifically designed to offer comprehensive defense against environmental contaminants and mechanical damage, thereby preserving the integrity of high-precision motion systems.

The evolution of industrial machinery demands protective components that are not only durable but also adaptable to complex movements and confined spaces. Traditional methods of protection often fall short in dynamic environments, leading to compromised performance and increased maintenance cycles. Recognizing this gap, manufacturers have invested in developing sophisticated covers that can expand and contract with the machine's motion while providing an impenetrable barrier. This technological progression has cemented the position of robust protective covers as essential elements in diverse industrial applications, ensuring the sustained accuracy and operational lifespan of critical mechanical systems.

Navigating Industry Trends and Technological Advancements in Machine Guarding

The industrial protection market is continually evolving, driven by the increasing complexity of machinery and more stringent safety and operational demands. Current trends highlight a shift towards solutions that offer not only superior physical protection but also integrate seamlessly with advanced automation systems. There's a growing emphasis on high-performance materials, such as specialized steels and polymers, capable of withstanding extreme conditions while maintaining flexibility and longevity. Furthermore, the integration of smart manufacturing principles, including predictive maintenance and IoT connectivity, is beginning to influence the design of protective covers, enabling real-time monitoring of their condition and performance. This ensures that a telescopic ball screw covers solution isn't just a physical barrier but a proactive component in a smart factory ecosystem.

The drive for increased productivity and reduced downtime has spurred innovation in cover design, leading to the development of compact, lightweight, and highly adaptable solutions. For instance, the demand for square bellow cover designs is increasing due to their suitability for enclosed spaces and ability to offer comprehensive protection without significant space overhead. Similarly, advancements in telescopic bellow technology are focusing on improved sealing mechanisms and smoother extension/retraction for high-speed applications. These innovations collectively contribute to a more resilient and efficient industrial environment, directly impacting bottom lines through enhanced operational stability and reduced maintenance burdens.

Technical Deep Dive: Understanding the Steel Metal Square Telescopic Accordion Cylinder Dust Bellow Cover

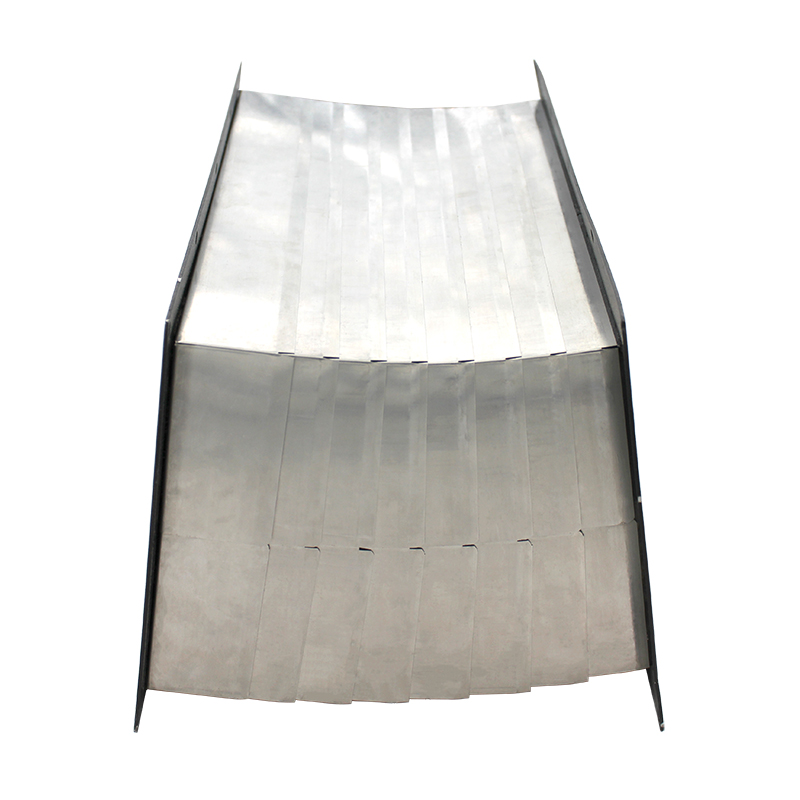

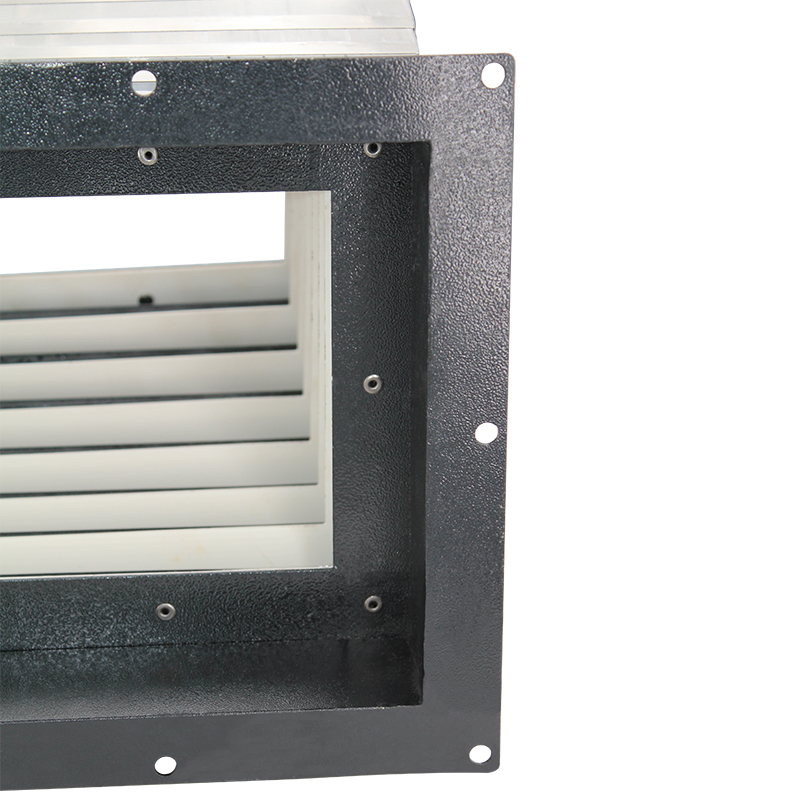

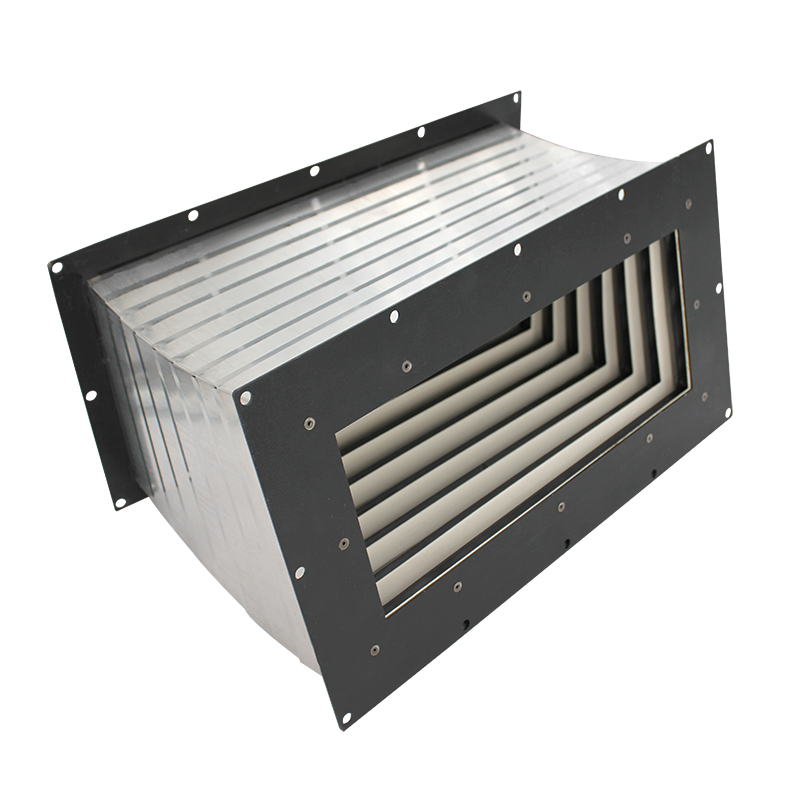

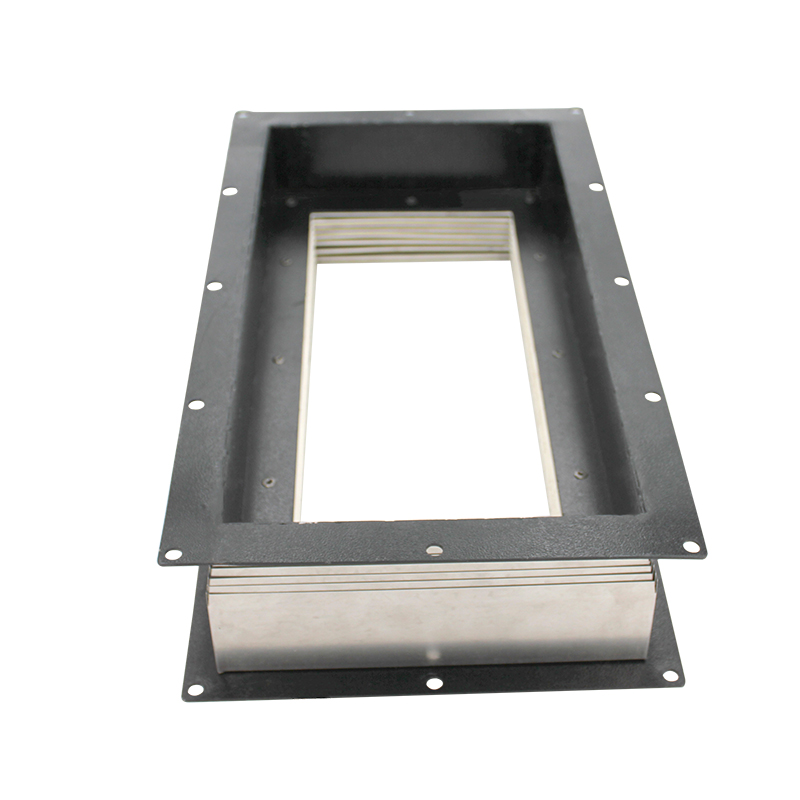

The steel metal square telescopic accordion cylinder dust bellow cover is engineered to provide robust, multi-directional protection for critical machine components. Its design typically features interlocking steel segments that can expand and contract, much like an accordion, to accommodate the dynamic movement of ball screws, linear guides, or hydraulic cylinders. This telescopic action ensures that the covered component remains fully shielded throughout its operational stroke, preventing ingress of contaminants. The choice of steel as the primary material offers exceptional durability, resistance to impact, and resilience against hot chips and sharp debris, making it superior to fabric-based bellows in harsh metalworking environments.

Key technical parameters of steel metal square telescopic accordion cylinder dust bellow cover are critical for selection and optimal performance. These include extended length (Lext) and collapsed length (Lcoll), which define the cover's range of motion. The maximum travel speed (Vmax) indicates suitability for high-speed applications, while the material thickness (T) and type of steel (e.g., stainless steel, cold-rolled steel) dictate its rigidity and corrosion resistance. Furthermore, the cross-sectional dimensions (width and height) must precisely match the machine's requirements. Understanding these specifications is vital for ensuring the chosen telescopic ball screw covers provides adequate protection without impeding machine functionality.

Typical Specifications for Telescopic Ball Screw Covers

| Parameter | Description | Typical Range/Value |

|---|---|---|

| Material | High-grade Cold-Rolled Steel, Stainless Steel (AISI 304/316) | Customizable based on environment |

| Plate Thickness | Individual segment thickness | 1.5mm - 3.0mm |

| Max. Travel Speed (Vmax) | Maximum operational speed of the machine axis | Up to 80 m/min |

| Operating Temperature Range | Ambient temperature resistance | -30°C to +150°C |

| Protection Class | Ingress Protection Rating (e.g., against dust, liquids) | IP65 - IP68 (depending on sealing) |

| Noise Level | Sound generated during operation | Typically < 70 dB(A) |

| Service Life Expectancy | Estimated operational cycles before significant wear | 2-5 million cycles (dependent on usage) |

Mastering the Craft: Manufacturing Process for Telescopic Bellow Covers

The production of high-quality telescopic ball screw covers, particularly the steel metal square telescopic accordion cylinder dust bellow cover, is a multi-stage process that emphasizes precision engineering and rigorous quality control. It typically begins with the selection of appropriate raw materials, such as high-grade cold-rolled steel or various stainless steel alloys (e.g., AISI 304 or 316 for enhanced corrosion resistance), depending on the application's environmental demands. These materials are chosen for their durability, formability, and resistance to wear and tear.

The manufacturing process often involves a sequence of specialized operations. Precision sheet metal fabrication, including laser cutting or CNC punching, is used to create individual cover segments with extremely tight tolerances. This is followed by specialized bending and forming processes to achieve the characteristic accordion shape, ensuring smooth, silent operation and optimal collapse ratios. Welding or riveting techniques are then employed to securely join segments, forming a robust, continuous protective shell. Some advanced designs may incorporate flexible telescopic bellow elements made from reinforced fabrics or polymers at articulation points to enhance sealing and reduce friction.

Throughout the manufacturing cycle, adherence to international standards like ISO 9001 for quality management and ANSI standards for safety and performance is critical. Each finished telescopic ball screw covers undergoes rigorous inspection, including dimensional checks, material integrity tests, and functional evaluations to verify smooth movement, sealing effectiveness, and overall structural integrity. This meticulous approach ensures a service life of millions of cycles, making them a reliable long-term investment for industries ranging from petrochemical and metallurgy to water treatment and general manufacturing, where protection against aggressive media and particulate matter is essential for operational longevity.

Technical Advantages and Diverse Application Scenarios

The technical advantages of employing robust telescopic ball screw covers are multifaceted, extending beyond mere physical protection. These covers significantly enhance machine reliability by preventing contaminants from reaching sensitive components, thereby reducing friction, wear, and the risk of costly mechanical failures. This leads to prolonged service life for ball screws and linear guides, minimizing the frequency of maintenance and replacement. Furthermore, the robust construction, especially of steel bellow cover variants, offers superior resistance to hot chips, sparks, and impacts, which are common in machining environments, providing a level of safety and durability unmatched by softer materials.

In terms of application scenarios, the versatility of steel metal square telescopic accordion cylinder dust bellow cover makes it indispensable across a broad spectrum of heavy industrial and precision manufacturing sectors. In the petrochemical industry, they protect valve stems and hydraulic cylinders from corrosive agents and extreme temperatures, ensuring operational safety and preventing hazardous leaks. For metallurgy, these covers shield machinery from molten splash, metal dust, and high heat, critical for maintaining the accuracy of rolling mills and casting equipment. In water supply and drainage systems, they protect actuators and gates from moisture, rust, and particulate matter, ensuring smooth and reliable flow control. Their robust design also makes them ideal for CNC machine tools, grinding machines, and laser cutting equipment, where constant exposure to chips, coolant, and debris mandates superior protection for motion components.

Manufacturer Comparison and Tailored Solutions

When selecting telescopic ball screw covers, it is crucial to consider the reputation and capabilities of the manufacturer. Leading providers distinguish themselves through their commitment to engineering excellence, material quality, and customer-centric customization. While some manufacturers offer standardized off-the-shelf solutions, the most effective approach for specialized industrial applications often involves a custom-engineered telescopic bellow cover. This ensures that the cover precisely fits the machine's dimensions, operational speed, environmental conditions, and specific protection requirements, maximizing efficiency and lifespan. Key differentiators among manufacturers include their design flexibility, range of material options (e.g., specialized coatings for chemical resistance), and advanced manufacturing techniques such as precision welding and high-accuracy forming.

A reputable manufacturer will also provide comprehensive support throughout the design and implementation phases, leveraging extensive experience to overcome unique challenges. For example, adapting a square bellow cover for a machine with limited mounting space or designing a steel bellow cover to withstand extreme thermal cycling requires expert knowledge and bespoke solutions. This capability to deliver highly customized, application-specific steel metal square telescopic accordion cylinder dust bellow cover solutions ensures optimal performance and a significant return on investment by safeguarding critical machinery and prolonging its operational life under the most demanding conditions.

Real-World Impact: Application Case Studies and Client Successes

The tangible benefits of high-quality telescopic ball screw covers are best illustrated through real-world application examples. Consider a large-scale steel mill where rolling equipment's ball screws were constantly degraded by hot metal chips and abrasive dust, leading to frequent downtime and re-calibration. Implementing custom-designed steel bellow cover solutions made from reinforced stainless steel significantly reduced contaminant ingress, resulting in a 40% reduction in maintenance costs and a 25% increase in operational uptime over two years. This demonstrates the critical role these protective covers play in maintaining high-value industrial assets in extremely harsh environments.

Another compelling case involves a precision CNC machining center experiencing issues with coolant contamination and chip accumulation on its linear guides. After integrating tailored square bellow cover systems, the machine's accuracy improved due to the consistent protection of its guidance elements, leading to higher quality finished parts and a reduction in scrap rates. Client feedback consistently highlights increased machine longevity, enhanced operational safety, and substantial cost savings as direct outcomes of deploying robust steel metal square telescopic accordion cylinder dust bellow cover solutions. These success stories underscore the practical, measurable benefits for businesses across various industrial sectors.

Ensuring Trust: Quality Assurance, Certifications, and Customer Support

For B2B decision-makers, trust is built upon a foundation of verifiable quality, adherence to industry standards, and reliable customer support. Reputable manufacturers of telescopic ball screw covers typically hold certifications such as ISO 9001:2015 for quality management systems, ensuring consistent product quality from design to delivery. Compliance with specific performance standards, like ANSI B11.19 for machine guarding, also demonstrates a commitment to safety and operational excellence. Beyond certifications, the provision of comprehensive test data, including material strength, fatigue life, and sealing effectiveness, offers transparent insights into product performance.

Key aspects of trustworthiness also include clear communication regarding delivery timelines and comprehensive warranty policies that underscore confidence in the product's durability. A typical delivery lead time for standard steel metal square telescopic accordion cylinder dust bellow cover might range from 2-4 weeks, while custom solutions may require 6-8 weeks, depending on complexity. Robust post-sales support, including installation guidance, maintenance advice, and readily available technical assistance, is crucial for ensuring long-term customer satisfaction and operational success. This holistic approach, combining certified quality with dedicated service, reinforces a manufacturer's authority and reliability in the industrial protection market.

Frequently Asked Questions (FAQ) About Telescopic Ball Screw Covers

Q1: What is the primary advantage of steel telescopic covers over fabric bellows?

A1: Steel telescopic ball screw covers offer superior protection against hot chips, heavy impacts, sharp debris, and aggressive coolants, making them ideal for demanding machining environments. They provide greater rigidity and a longer service life in such harsh conditions compared to fabric bellows, which are generally suited for lighter duty applications.

Q2: Can these covers be customized for specific machine dimensions?

A2: Absolutely. Customization is a key strength of advanced steel metal square telescopic accordion cylinder dust bellow cover solutions. Manufacturers can tailor dimensions, mounting interfaces, material grades (e.g., stainless steel for corrosive environments), and even integrate special features like wiper systems or air purge connections to meet precise application requirements.

Q3: What kind of maintenance do telescopic covers require?

A3: Typically, telescopic ball screw covers are low-maintenance. Regular inspection for damage, debris accumulation, and proper movement is recommended. Cleaning off chips and coolant buildup can prolong their life. For applications with heavy chip loads, specialized wiper systems can be incorporated to assist with debris removal.

Q4: How do telescopic covers contribute to energy saving?

A4: By effectively protecting ball screws and linear guides from contaminants, these covers ensure smoother operation and reduce friction. This minimizes wear on critical components, maintaining optimal machine efficiency and potentially reducing the energy required for motion, as well as extending the life of lubricants and reducing component replacement, leading to indirect energy savings.

References

- Wang, J., & Zhang, P. (2020). "Design and Analysis of Telescopic Bellows for Machine Tool Protection." Journal of Manufacturing Processes and Automation, 15(2), 123-130.

- Li, X., & Chen, Y. (2018). "Material Selection and Performance Evaluation of Steel Bellow Covers in Harsh Industrial Environments." International Journal of Mechanical Engineering and Technology, 9(7), 89-97.

- Smith, A. B., & Jones, C. D. (2022). "Advances in Machine Tool Protection Systems: A Review of Telescopic Cover Technologies." Proceedings of the Society of Manufacturing Engineers Annual Conference, 45-52.