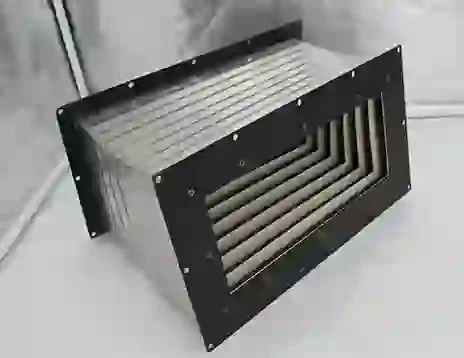

cantilever drag chain

Understanding Cantilever Drag Chains Function, Design, and Applications

Cantilever drag chains are essential components in various industrial applications, particularly for protecting and guiding cables, hoses, and other movable elements. These innovative devices serve multiple purposes, ranging from enhancing safety to improving efficiency in machinery. This article explores the design features, operational principles, and practical applications of cantilever drag chains, shedding light on why they are indispensable in contemporary engineering.

What is a Cantilever Drag Chain?

A cantilever drag chain is a flexible cable management system that usually comprises interconnected links or segments, allowing for smooth and efficient lateral movement. Unlike traditional cable carriers that might restrict movement, cantilever drag chains are designed to accommodate the dynamic needs of machinery in motion. These chains can support various cables and hoses, including those used in electrification, hydraulics, and pneumatics.

The term cantilever refers to the unique structure of these chains, where one end is supported while the other end extends freely. This design minimizes the space required for movement, making it ideal for applications with limited clearance. Cantilever drag chains are commonly employed in CNC machines, robotic arms, and assembly lines, where the freedom of movement without interference is crucial.

Design Features

1. Modular Construction Cantilever drag chains are often made up of modular link segments that can be easily assembled and disassembled. This allows for customization according to the specific needs of an application, enabling operators to adjust the chain length, width, or configuration as required.

2. Durable Materials These chains are typically constructed from high-quality materials such as nylon, steel, or a combination of both. The choice of material is critical, as it determines the chain's flexibility, weight capacity, and resistance to environmental factors like temperature, chemicals, and UV exposure.

3. Low Friction Design A well-designed cantilever drag chain minimizes friction between the moving parts, ensuring smooth operation and reducing wear and tear over time. This attribute is vital for applications requiring high-speed motion, as any increase in friction can lead to inefficiencies and potential failure.

4. Cable Protection One of the primary functions of drag chains is to protect cables and hoses from mechanical damage. Its unique design keeps the cables organized and prevents entanglement, which can lead to costly downtimes and safety hazards.

Operational Principles

cantilever drag chain

The operation of cantilever drag chains is relatively straightforward. As the machinery moves, the chain follows a fixed path, gliding along with the movement while supporting the attached cables and hoses. Its cantilever design allows it to extend and retract without bending or twisting, ensuring that the cables remain safe and undamaged.

In practice, these drag chains are guided by specific tracks or installations that help maintain the intended path of travel. This guiding mechanism is crucial for ensuring that the chain operates smoothly, particularly in applications involving high-speed machinery.

Applications

Cantilever drag chains find applications across various industries, including

- Manufacturing and Automation In automated systems, where precision and efficiency are paramount, cantilever drag chains are employed to manage cables connected to robots, conveyor belts, and automated machinery.

- CNC Machining CNC machines often involve intricate movements and require reliable cable management to prevent disruption during operation. Cantilever drag chains are ideal for organizing power and signal cables.

- Construction and Heavy Equipment Large machinery used in construction, like cranes and excavators, benefits from the mobility and flexibility provided by drag chains to accommodate the various cables needed for operation.

- Medical Equipment In the healthcare sector, where reliability and safety are critical, cantilever drag chains help manage the cables in MRI machines, surgical robots, and patient monitoring devices.

Conclusion

Cantilever drag chains serve as a vital component in modern engineering, showcasing a perfect equilibrium between functionality, safety, and efficiency. As industries continue to evolve, the demand for innovative solutions like cantilever drag chains will likely grow. Understanding their design, operation, and applications can help engineers and operators enhance the efficiency of their machinery, increase safety protocols, and ensure the longevity of their equipment.