synchronous belt vs timing belt

Synchronous Belt vs. Timing Belt Understanding the Key Differences

When it comes to mechanical engineering and automotive applications, two terms often surface synchronous belts and timing belts. While these terms are frequently used interchangeably, they represent specific types of belts with distinctive characteristics and functions. In this article, we delve into the details of synchronous belts and timing belts, examining their differences, applications, and advantages.

What is a Synchronous Belt?

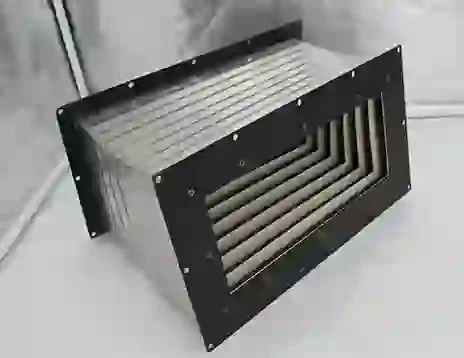

A synchronous belt is a toothed belt designed to synchronize the rotation of shafts in machinery. It typically has teeth that lock into corresponding grooves on pulleys, enabling precise transfer of power without slippage. This design ensures that the belt maintains consistent timing and alignment, making it ideal for applications where exact positioning is crucial.

Synchronous belts are commonly made from materials such as neoprene or polyurethane reinforced with fiberglass or steel. They are known for their durability, resistance to wear, and ability to operate under varying temperatures. These belts are often used in applications such as conveyor systems, robotics, and industrial machinery where reliable performance and longevity are required.

What is a Timing Belt?

Timing belts, on the other hand, are predominantly associated with automotive engines. They serve a similar purpose in that they manage the timing of engine components, specifically the connection between the crankshaft and the camshaft. By ensuring that these components are synchronized, timing belts help maintain the engine’s optimal performance. Like synchronous belts, timing belts also feature teeth, which engage with the gears of the pulleys to eliminate slippage.

Typically made from high-strength rubber and reinforced with materials such as polyester, timing belts are designed to withstand the high temperatures and tension found within an engine compartment. Timing belts usually have a specific replacement interval, as they are subject to wear and tear due to constant exposure to heat and mechanical stress.

Key Differences

synchronous belt vs timing belt

While both synchronous belts and timing belts share similar traits, the primary differences lie in their applications and construction. Synchronous belts are more versatile and can be found across various industries, while timing belts are specifically engineered for automotive engines.

2. Tooth Design The tooth design on a synchronous belt is often broader and deeper to accommodate a wider range of machinery, whereas timing belts are designed with specific tooth profiles that match the engine’s timing requirements.

3. Application Scope Timing belts are critical in automotive engineering, directly affecting the engine's performance and timing. In contrast, synchronous belts have industrial applications—such as in robotics and conveyor systems—where exact timing and load stability are essential.

Advantages

Both belts offer unique advantages tailored to their respective uses. Synchronous belts provide high levels of efficiency, low noise operation, and reduced maintenance needs, making them ideal for various industrial applications. Their ability to handle heavy loads and operate at different speeds adds to their versatility.

Timing belts, meanwhile, ensure engine components operate in perfect harmony, which is crucial for vehicle performance. They offer a lightweight solution compared to chain systems and can significantly reduce engine noise. Proper maintenance of timing belts is essential, as failure can lead to severe engine damage.

Conclusion

Understanding the differences between synchronous belts and timing belts is essential for anyone involved in mechanical engineering or automotive maintenance. While both types of belts play critical roles in their respective fields, their applications, materials, and designs cater to very different needs. When selecting the appropriate belt for a project, carefully considering these factors will ensure optimal performance and longevity. Whether you’re operating a factory machine or maintaining a car engine, choosing the right belt can make all the difference.