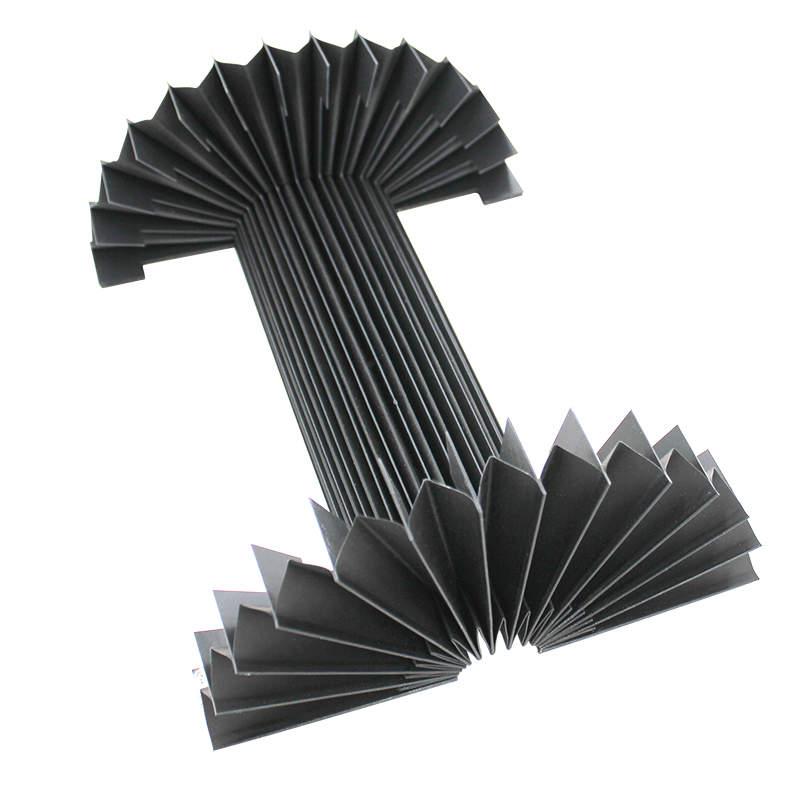

corrugated loom tubing

The Versatility and Benefits of Corrugated Loom Tubing

Corrugated loom tubing, often simply referred to as loom tubing, is an essential component in various industries, playing a crucial role in the management of cables and wires. This innovative solution is designed to protect and bundle electrical wires, making it an invaluable asset in both commercial and residential applications. Its unique structure and material properties offer a range of advantages that contribute to its widespread use.

One of the primary benefits of corrugated loom tubing is its extraordinary flexibility. The tubing is designed with a corrugated surface that allows it to bend and flex without compromising its structural integrity. This adaptability makes it ideal for environments where wires and cables need to navigate tight corners or complex pathways. Unlike rigid conduit options, loom tubing can easily conform to the layout of a project, ensuring that wiring remains organized and easily accessible.

In addition to flexibility, the protective qualities of corrugated loom tubing are significant. It is typically made from durable materials such as polyethylene or PVC, which are resistant to abrasion, moisture, and various chemicals. This makes loom tubing an excellent choice in environments that may expose wiring to potential damage, such as automotive applications or industrial settings. By encasing wires in loom tubing, users can prevent fraying, cuts, and exposure to corrosive substances, thereby prolonging the lifespan of electrical components.

Another advantage of corrugated loom tubing is its lightweight nature. Unlike traditional metal conduits, the lightweight structure of loom tubing means that it is easier to transport, handle, and install. This not only saves labor costs but also simplifies the installation process, allowing for a quicker and more efficient setup. The reduced weight does not compromise the strength of the tubing, making it a practical choice for a variety of applications.

corrugated loom tubing

Furthermore, corrugated loom tubing simplifies the management of wires and cables. The ability to bundle multiple wire types together helps in organizing installations and prevents tangling. This organizational aspect is crucial in aerospace, automotive, and telecommunications industries where a multitude of wires are in use. A well-organized wiring system not only enhances functionality but can also contribute to a cleaner and more professional aesthetic in an installation.

In the context of safety, corrugated loom tubing provides an additional layer of protection. It acts as a barrier against electrical shorts and can minimize the risk of fire hazards caused by exposed wires. By using loom tubing to cover electrical wiring, users can adhere to safety codes and regulations while ensuring that their installations are compliant.

Corrugated loom tubing is also available in various sizes and colors, providing users with options tailored to specific needs. Different diameters accommodate various wire sizes, and color coding can aid in easily identifying circuits and connections. This level of customization makes loom tubing not just a functional component but also a well-integrated part of any electrical system.

In conclusion, corrugated loom tubing is a versatile and advantageous solution for managing wires and cables. Its flexibility, protective qualities, lightweight nature, organizational capabilities, and safety features make it an essential material in numerous applications. Whether in residential, commercial, or industrial settings, the use of loom tubing can enhance both the performance and longevity of electrical systems. As technology continues to evolve, the importance of effective cable management solutions like corrugated loom tubing will undoubtedly remain central to maintaining efficient and safe electrical installations.