Efficient Solutions for Handling Swarf with Modern Conveyor Systems

The Importance of Swarf Conveyors in Modern Manufacturing

In the modern manufacturing environment, efficiency and productivity are critical factors that determine a company's competitiveness. One often overlooked but essential component in this sector is the swarf conveyor. A swarf conveyor is a mechanical system designed to transport metal shavings, chips, and scrap materials generated during machining processes. With the continuous advancements in technology and industry practices, the significance of swarf conveyors has grown immensely.

What is Swarf?

Swarf refers to the byproducts of machining processes, such as drilling, milling, grinding, and turning. These byproducts can take the form of chips, fines, or shavings and are often made of metals or alloys. When machining metals, the removal of material is inevitable, leading to the generation of swarf. Managing swarf effectively is crucial for maintaining a clean workspace, ensuring the safety of workers, and facilitating recycling or disposal processes.

Why Use Swarf Conveyors?

1. Efficiency in Operation Swarf conveyors are designed to transport waste materials efficiently from the production area to a designated disposal or recycling point. By automating the removal of swarf, manufacturers can minimize downtime associated with manual cleanup efforts, allowing machinery to operate continuously without interruption.

2. Improved Workplace Safety Accumulated swarf can pose safety hazards in the manufacturing environment. It can lead to slips, trips, and falls, as well as potential injuries from sharp metal fragments. By implementing a swarf conveyor system, companies can keep work areas tidy, reducing the risk of accidents and ensuring a safer work environment for employees.

3. Cost Savings While swarf conveyors involve an initial investment, they can result in significant long-term cost savings. By efficiently removing waste materials, companies can reduce the costs associated with labor for manual cleanup and lower the risk of damage caused by swarf accumulation. Furthermore, effective swarf management allows for the recycling of materials, contributing to overall material cost reduction.

4. Environmental Impact As industries strive to become more sustainable, effective waste management practices are paramount. Swarf conveyors aid in the proper disposal or recycling of metal chips and shavings, reducing the environmental footprint of manufacturing operations. By channeling swarf directly into recycling processes, manufacturers can contribute to a circular economy, reducing waste and promoting resource conservation.

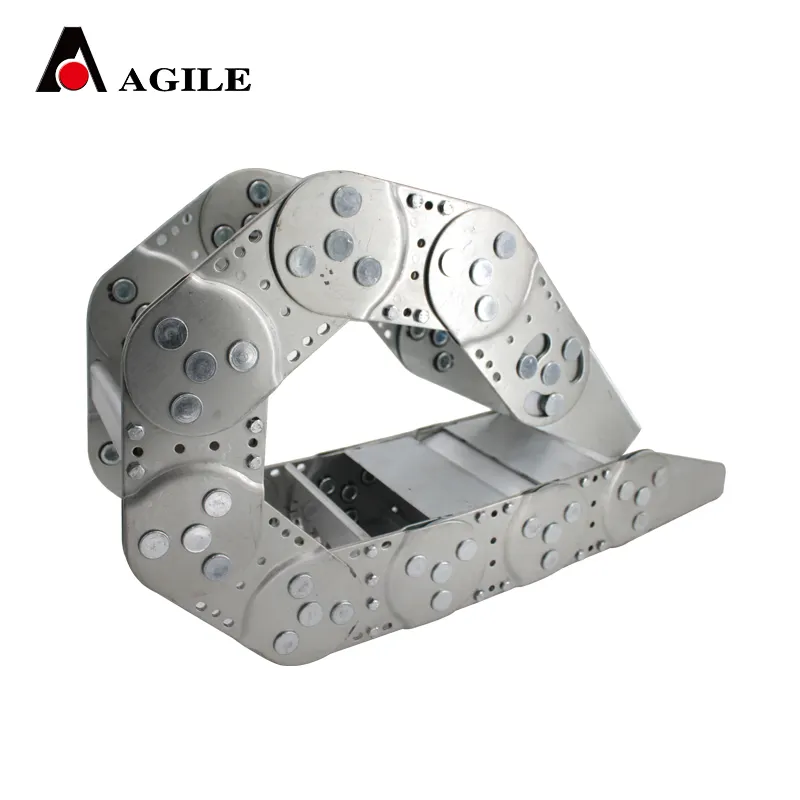

swarf conveyors

Types of Swarf Conveyors

There are several types of swarf conveyors available, each designed for specific applications. Some of the most common types include

- Auger Conveyors These utilize a rotating helical screw to move swarf. They are effective for transporting dry and free-flowing materials.

- Drag Chain Conveyors These systems use chains fitted with paddles to drag swarf along a trough, accommodating various materials.

- Belt Conveyors These systems use a belt to transport swarf and are often used when a more delicate handling process is needed.

- Magnetic Chip Conveyors These are designed for ferrous materials, using magnetic forces to move swarf without contact, preventing damage to the material.

Conclusion

In conclusion, swarf conveyors play an essential role in modern manufacturing environments by enhancing operational efficiency, improving workplace safety, generating cost savings, and contributing to environmental sustainability. As the industry moves towards more automated and efficient processes, the importance of swarf management cannot be overstated. Investing in a reliable swarf conveyor system is not just a smart choice; it is vital for maintaining a competitive edge in today's fast-paced manufacturing landscape. For companies looking to optimize their operations and enhance productivity, implementing an effective swarf conveyor solution is a step in the right direction.