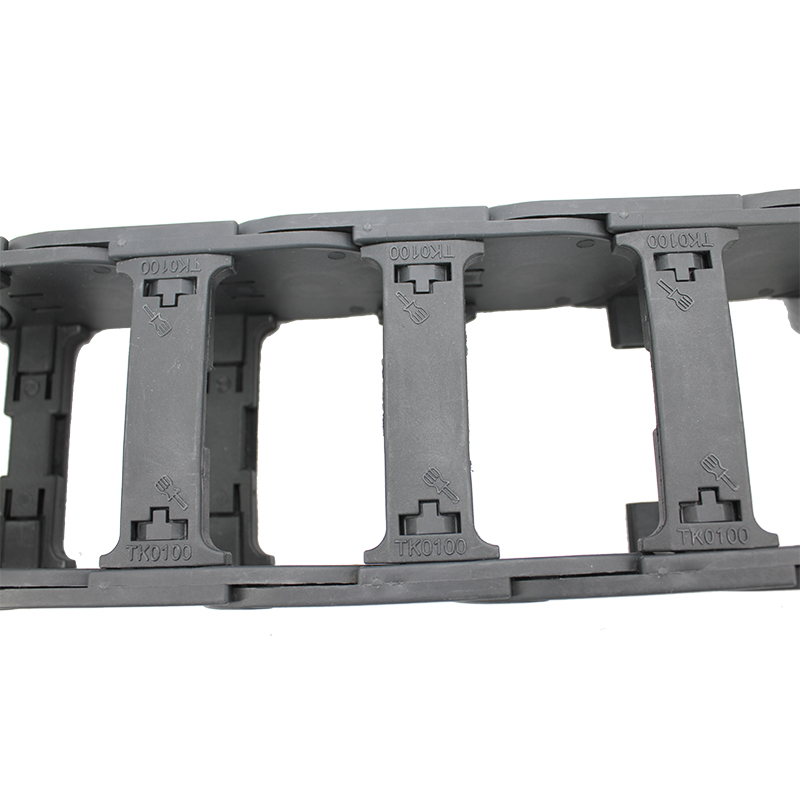

Durable Plastic Cable Carrier for Efficient Drag Chain Applications

Understanding Plastic Drag Chain Cable Carriers

In the modern manufacturing and automation sectors, the need for efficient cable management solutions is paramount. One such innovation that has gained popularity is the plastic drag chain cable carrier. These specialized carriers are designed to protect and guide cables and hoses during the operation of machinery, ensuring both safety and enhanced performance. This article delves into the features, benefits, and applications of plastic drag chain cable carriers.

What is a Plastic Drag Chain Cable Carrier?

A plastic drag chain cable carrier, often referred to as a cable drag chain or energy chain, consists of interlinked plastic sections that form a flexible, elongated channel. This channel accommodates various types of cables and hoses, allowing them to move freely while providing protection from mechanical wear and environmental factors. The design typically features a series of links that can bend in various directions, making them ideal for applications with moving parts, such as robotic arms and CNC machines.

Key Features

1. Material Composition As the name suggests, plastic drag chains are primarily made from high-quality plastics like nylon, polyamide, or polycarbonate. These materials offer excellent wear resistance, flexibility, and the capability to endure harsh environments. The lightweight nature of plastic also contributes to reduced overall machine weight.

2. Modular Design Many plastic drag chains are designed to be modular, which means they can be easily assembled and customized according to specific requirements. This feature allows for easy installation and modification, accommodating various lengths and configurations.

3. Bend Radius The bend radius of a drag chain is crucial for its performance. Manufacturers often provide guidelines on the minimum bend radius to ensure the longevity of the cables inside the chain. The flexibility of the chain allows for tight bends, which is essential in compact machinery setups.

4. Noise Reduction Plastic drag chains can significantly reduce noise levels compared to metal alternatives, making them suitable for environments where minimal noise is desired. The plastic materials absorb vibrations, contributing to a quieter operation.

5. Chemical Resistance Depending on the type of plastic used, drag chains can exhibit a high degree of resistance to various chemicals, oils, and lubricants. This makes them suitable for use in industries such as food processing, pharmaceuticals, and manufacturing.

Benefits

The incorporation of plastic drag chains into machinery design offers numerous advantages

plastic drag chain cable carrier

- Enhanced Protection By encapsulating cables and hoses, drag chains protect them from abrasion, crushing, and exposure to contaminants

. This protection extends the lifespan of the cables and reduces the need for frequent replacements.- Improved Flexibility The ability to bend and twist without affecting the internal cables allows for greater design flexibility in machinery. This is particularly important in applications where space is at a premium.

- Simplified Maintenance With a drag chain in place, maintenance personnel can easily access cables and hoses for inspection or replacement without the need to disassemble large sections of machinery.

- Increased Safety Proper cable management helps prevent tripping hazards and reduces the risk of damage to electrical components, contributing to a safer work environment.

Applications

Plastic drag chain cable carriers find widespread use across various industries

- Manufacturing Used in assembly lines, CNC machines, and robotic automation, they ensure that power and control signals are consistently delivered to moving equipment.

- Automotive In automotive production, drag chains help manage the numerous cables associated with electronic components in vehicles, including sensors, cameras, and navigation systems.

- Food and Beverage Due to their chemical resistance and easy cleaning capabilities, plastic drag chains are ideal for use in food processing machinery where hygiene is a priority.

- Packaging In packaging equipment, they manage cables for actuators, conveyors, and sensors, facilitating smooth operation and minimizing downtime.

Conclusion

Plastic drag chain cable carriers represent a practical solution for modern cable management challenges. Their versatility, protective features, and flexibility make them indispensable in a variety of industries. As technology continues to evolve, the advancements in drag chain design and materials promise to further enhance the efficiency and safety of machinery worldwide. Integrating these plastic cable carriers into new and existing systems can lead to improved operational performance, reduced maintenance costs, and a safer working environment.