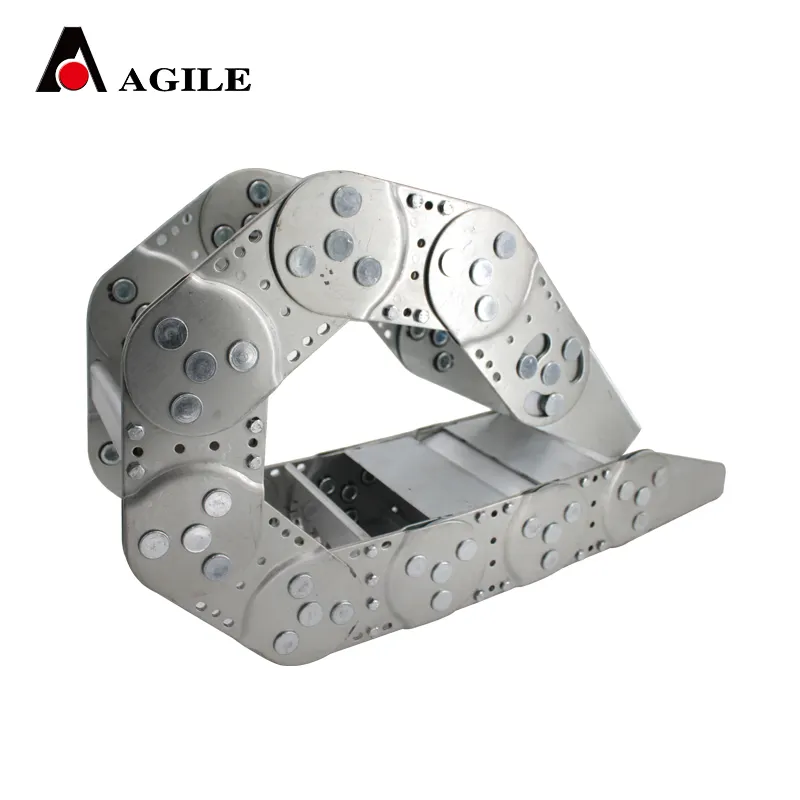

dust free cable carrier

Dust-Free Cable Carriers Ensuring Clean and Efficient Operations

In an increasingly automated world, the importance of maintaining a clean and efficient work environment cannot be overstated. One of the often-overlooked components in industrial settings is the cable carrier system, which plays a crucial role in the management of cables and hoses. Among various types of cable carriers, dust-free cable carriers stand out for their ability to maintain hygiene and efficiency in a variety of applications, from manufacturing and robotics to packaging and automotive industries.

What Are Cable Carriers?

Cable carriers, also known as drag chains or energy chains, are designed to guide and protect moving cables and hoses. They facilitate smooth cable movement in systems where mobility is necessary, such as robotic arms, conveyor belts, and CNC machines. These systems are constructed to prevent cable entanglement, wear, or damage, thus extending the lifespan of the cables and ensuring reliable operation.

The Need for Dust-Free Environments

In industries like electronics, food processing, pharmaceuticals, and cleanroom environments, contamination by dust and particulates can lead to serious operational issues. Dust accumulation can interfere with machinery performance, cause product contamination, and pose health risks to workers. Therefore, maintaining a dust-free environment is not just a matter of aesthetics but a critical aspect of operational integrity.

The Advantages of Dust-Free Cable Carriers

Dust-free cable carriers are specifically designed to minimize the accumulation of dirt and debris. Their construction typically involves smooth, enclosed designs that prevent dust from entering the carrier itself. Here are some significant advantages they offer

1. Enhanced Cleanliness Dust-free cable carriers provide a barrier against contaminants. They help maintain a clean operational environment, which is essential in industries where cleanliness is crucial. For instance, in electronics manufacturing, even tiny particles of dust can lead to significant defects.

2. Improved Safety The enclosure of cables and hoses in a fitted cable carrier helps reduce slip hazards on factory floors. By securing cables in designated paths, they minimize the chances of tripping or snagging, thus enhancing worker safety.

3. Reduced Maintenance Dust accumulation can lead to wear and tear on cables and machinery. By utilizing dust-free systems, companies can decrease maintenance requirements, as the cables are better protected against environmental factors.

dust free cable carrier

4. Increased Efficiency A clean operational environment allows machinery to run more smoothly without interruptions caused by debris or equipment malfunctions. This reliability translates into enhanced productivity, as machines can operate without frequent downtime for cleaning or repairs.

5. Versatility Dust-free cable carriers are suitable for various applications, from indoor environments susceptible to dust and dirt to outdoor environments requiring durable solutions. Their adaptability makes them an essential component in many industries.

Choosing the Right Dust-Free Cable Carrier

When selecting a dust-free cable carrier system, a few factors should be considered

- Material The material used in the construction of the cable carrier can impact its resistance to dust and other contaminants. Many manufacturers offer materials that are not only durable but also resistant to various chemicals and temperatures.

- Size and Configuration Cable carriers come in various sizes and configurations, allowing businesses to select a model that fits their specific needs. Consideration of the number and size of cables to be managed is essential for optimizing performance.

- Application Different applications may require specialized carriers. For instance, robotic operations may require flexible carriers that can withstand constant movement, while static applications might need sturdier, more rigid models.

- Maintenance and Support Understanding the maintenance needs and the level of support available from the manufacturer is vital. Ideally, the chosen system should be easy to install, maintain, and replace.

Conclusion

In summary, dust-free cable carriers provide crucial benefits in maintaining cleaner and more efficient industrial environments. By safeguarding cables and hoses from dirt and damage, these systems not only enhance operational safety and reliability but also extend equipment lifespan. As industries continue to evolve and prioritize cleanliness, the adoption of dust-free cable carriers will likely become a standard practice, ensuring optimal performance and productivity across the board. Investing in such systems is an investment in the overall efficiency and safety of the workplace.