Exploring the Features and Benefits of CNC Bellow Covers for Machinery Protection

Understanding CNC Bellow Covers Their Importance and Applications

CNC machinery has revolutionized the manufacturing industry, enabling precision engineering that was previously unimaginable. One critical component in this realm is the bellow cover, often referred to simply as a bellow. These protective covers play an indispensable role in enhancing the longevity and efficiency of various CNC machines.

What is a Bellow Cover?

A bellow cover is a protective sleeve made from flexible materials, designed to shield the linear motion components of CNC machines from debris, coolant, and other contaminants. The structure typically consists of a series of folds or bellows, allowing it to expand and contract as the machine operates. This flexibility ensures that the bellow can accommodate the dynamic movements inherent in CNC machining processes.

Importance of Bellow Covers

1. Protection Against Contaminants One of the primary roles of bellow covers is to protect the internal components of CNC machines, such as guideways and ball screws, from dirt, chips, and other harmful materials. Contaminants can cause wear and tear, leading to costly repairs and downtime.

2. Maintaining Precision CNC machines are known for their precision. Any foreign material that compromises the integrity of the machine can negatively impact its accuracy. Bellow covers play a vital role in maintaining the operational effectiveness of machines by preventing debris from interfering with their precise movements.

3. Reducing Maintenance Costs By protecting critical components, bellow covers reduce the frequency of maintenance and repair. This not only saves costs in terms of parts and labor but also minimizes the risk of unexpected downtimes that can disrupt production schedules.

4. Enhancing Machine Lifespan The longevity of CNC machines is enhanced when components are kept clean and free from contaminants. Bellow covers effectively increase the lifespan of machines, ensuring that investments in CNC technology yield long-term benefits.

5. Safety In addition to their protective benefits, bellow covers also contribute to the overall safety of the work environment. They prevent moving parts from becoming accessible, reducing the risk of accidents involving operators.

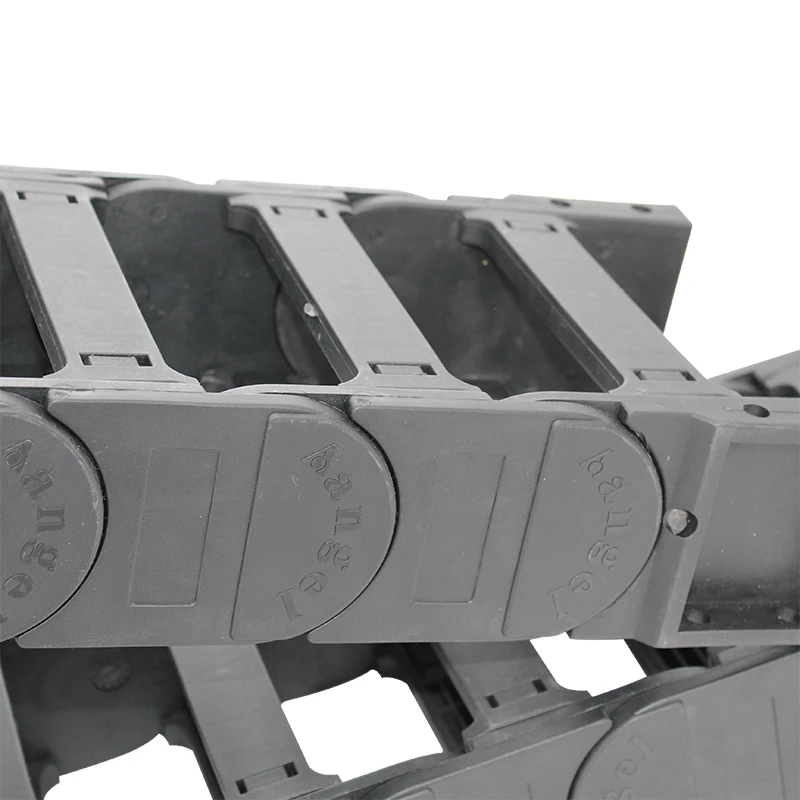

cnc bellow cover

Materials and Design Considerations

Bellow covers are typically made from materials such as rubber, polyurethane, or vinyl, which provide the necessary flexibility and durability. The choice of material largely depends on the specific industrial application, as well as the environmental conditions to which the bellow cover will be exposed.

When designing a bellow cover, several factors need to be considered

- Size and Dimensions The cover must fit appropriately to ensure maximum protection without hindering the movement of the machine parts. - Temperature Resistance In high-temperature environments, selecting a bellow material that can withstand such conditions without degrading is essential. - Chemical Resistance For CNC machines that operate in environments exposed to various chemicals, the bellow material must be resistant to corrosion and degradation.

Applications of Bellow Covers

Bellow covers find applications across various industrial sectors, including

- Manufacturing Used in CNC milling machines, lathes, and laser cutters to protect critical components from debris. - Automotive Employed in robotic arms and assembly lines to ensure precision manufacturing and reduce the risk of mechanical failures. - Aerospace Critical in maintaining the integrity of CNC machines used in aircraft components, where precision is paramount.

Conclusion

Bellow covers are a simple yet effective solution for protecting CNC machinery, enhancing operational efficiency, and ensuring safety in manufacturing environments. Their ability to guard against contaminants and physical damage is a vital contribution to the overall functionality and lifespan of CNC machines. As technology advances and manufacturing processes become increasingly complex, the significance of bellow covers will only grow, highlighting their essential role in modern engineering. Investing in quality bellow covers is not merely a precaution; it is a strategic move towards sustaining the high standards of precision and reliability that characterize the CNC industry.