Wire Cable Track Design for Efficient Management and Organization in Various Applications

Exploring Wire Cable Track A Vital Component in Modern Industries

In today’s fast-paced industrial environment, efficient organization and management of wire cables are crucial for ensuring safety, reliability, and productivity. One significant innovation that has addressed this need is the wire cable track. This system not only contributes to the neat arrangement of cables but also enhances overall operational performance in various sectors, including manufacturing, logistics, and telecommunications.

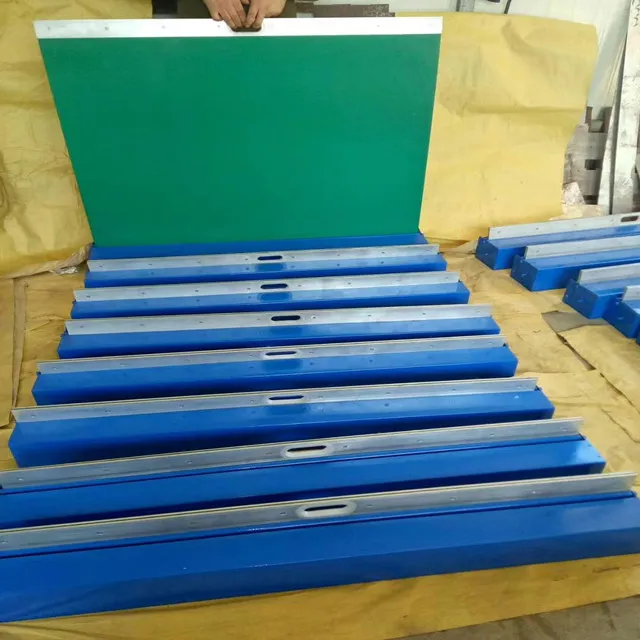

Wire cable tracks serve as dedicated pathways for electrical cables and wires, allowing them to be systematically organized. These tracks are designed to protect cables from wear and tear, exposure to harmful elements, and potential damage caused by equipment movement. By utilizing wire cable tracks, businesses can reduce the risks associated with tangled or improperly managed cables, which can lead to accidents or downtime.

One of the primary benefits of wire cable tracks is their ability to facilitate smooth movement within industrial settings. In manufacturing plants where machinery operates on a continuous basis, flexible cable tracks enable the free movement of cables along with moving equipment. This not only prevents cable damage but also simplifies maintenance, as cables can be easily accessed without disrupting the operation of the machinery.

Another important aspect of wire cable tracks is their role in enhancing electrical safety. Exposed cables can pose significant hazards, including electrical shocks and fires. By using wire cable tracks, companies can ensure that wires are contained securely, significantly reducing the likelihood of accidents. Additionally, many wire cable track systems feature built-in fire resistance, further improving safety protocols within the workplace.

wire cable track

Wire cable tracks are also designed for excellent adaptability. They come in various designs and materials, such as plastic, metal, or rubber, catering to the specific needs of different industries. For instance, in environments where chemical exposure is a concern, a resistant material can be selected, allowing the wires to operate safely without deterioration. Moreover, tracks can be configured in numerous ways—straight, curved, or even vertical—helping businesses maximize space while maintaining functionality.

Furthermore, implementing wire cable tracks can lead to long-term cost savings. While the initial investment may seem considerable, the reduction in equipment damage, maintenance costs, and safety-related incidents can lead to substantial savings over time. Additionally, organized cable management can improve the overall efficiency of operations, as workers spend less time troubleshooting cable issues and more time focusing on their core tasks.

Finally, as industries continue to move toward automation and advanced technologies, the need for effective wire management systems becomes even more imperative. With the rise of robotics and complex machinery, wire cable tracks will play a critical role in ensuring that these sophisticated systems function seamlessly.

In conclusion, wire cable tracks are a foundational component of modern industry, offering a reliable solution for cable management. Their ability to improve safety, enhance operational efficiency, and provide adaptability makes them indispensable in today’s technological landscape. As industries evolve, the significance of wire cable tracks will undoubtedly continue to grow, shaping the future of cable management solutions in various sectors. Investing in these systems is not only a smart move for current operational needs but also a strategic decision for future developments.