Exploring the Benefits of Split Corrugated Conduit for Electrical Applications

Understanding Split Corrugated Conduit Features and Applications

In the realm of electrical wiring and protection, the choice of conduit is critical for ensuring safety and longevity. Among the various types available, split corrugated conduit has gained significant attention due to its unique features and versatile applications. This article delves into what split corrugated conduit is, its benefits, and where it is most commonly used.

What is Split Corrugated Conduit?

Split corrugated conduit is a type of flexible tubing made from high-density polyethylene (HDPE) or similar materials. Its design includes a corrugated texture that provides flexibility and strength, along with a split along its length that allows for easy installation around existing cables or wires. This split design differentiates it from traditional non-split conduits, making it particularly useful in situations where retrofitting or accessibility is necessary.

Key Features

1. Flexibility The corrugated nature of this conduit allows it to bend and twist, accommodating various installation pathways without compromising the protection of the wires inside. This flexibility is essential when working in tight spaces or when angles change frequently.

2. Ease of Installation The split design means that wires can be inserted without the need to pull them through an entire length of conduit. This feature is especially advantageous in renovations or repairs, where existing installations cannot be easily dismantled.

3. Durability Made from robust materials, split corrugated conduit is resistant to environmental factors such as moisture, chemicals, and UV rays. This durability enhances its suitability for both indoor and outdoor applications.

4. Protection The primary function of any conduit is to protect electrical wires from physical damage, abrasion, and environmental hazards. Split corrugated conduit excels in this regard, safeguarding the integrity of the wires it encases.

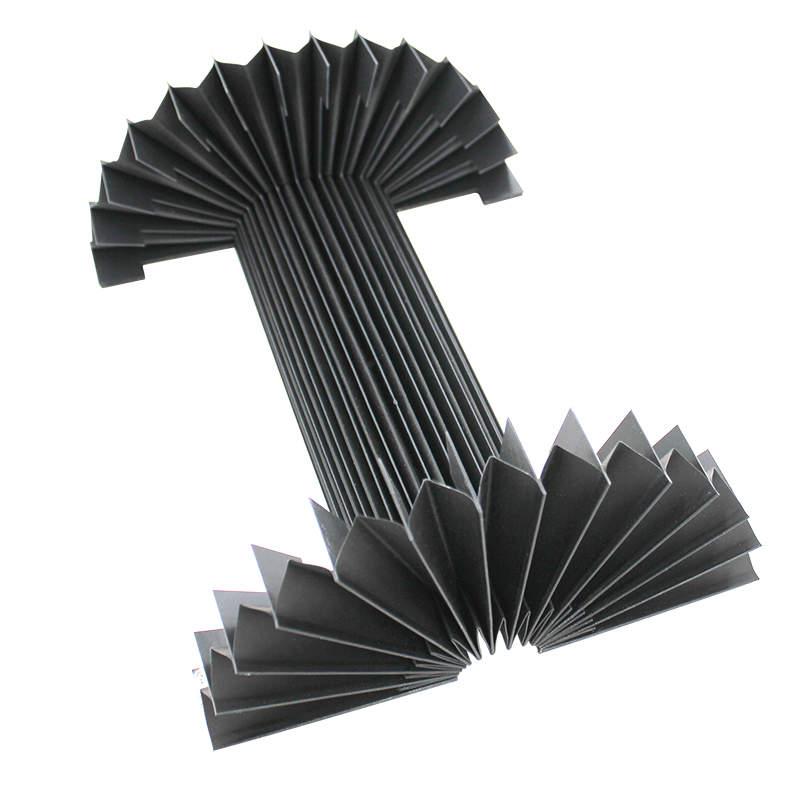

split corrugated conduit

Common Applications

Split corrugated conduit finds applications across a wide range of industries

- Construction and Renovation It is commonly used in new construction projects as well as in remodeling jobs, where existing wiring needs protection without extensive dismantling.

- Automotive In vehicle wiring, split corrugated conduit is often used to protect and organize electrical harnesses, ensuring that wires are shielded from mechanical damage and environmental factors.

- Industrial Settings Factories and workshops utilize split corrugated conduit to manage and protect wiring for machinery, reducing wear and tear and improving safety.

- Telecommunication In the telecommunications sector, this conduit is employed to house fiber optic and copper cables, protecting them from physical damage and environmental challenges.

- Home Electronics Many homeowners and DIY enthusiasts use split corrugated conduit to manage cables for home entertainment systems, computer networks, and other electrical installations, enhancing aesthetics and safety by keeping wires organized.

Conclusion

Split corrugated conduit offers a practical and efficient solution for protecting electrical wires in various settings. Its flexibility, ease of installation, and durability make it a preferred choice in both professional environments and DIY projects. As technology continues to advance and electrical installations become increasingly complex, the importance of using reliable conduits like split corrugated types will only grow, ensuring the safety and longevity of electrical systems everywhere. Whether in construction, automotive applications, or home projects, understanding the benefits of split corrugated conduit can guide professionals and enthusiasts alike in making informed choices for their wiring needs.