bellow dust cover

Understanding the Importance of a Below Dust Cover

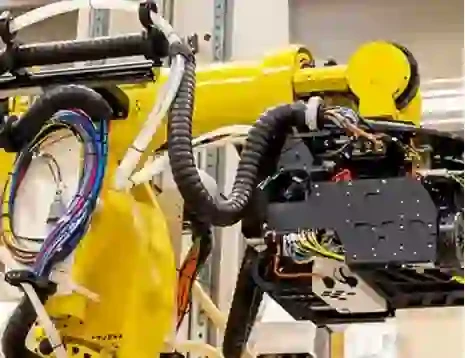

In many industries, particularly in the field of manufacturing and electronics, maintaining the cleanliness and integrity of machinery and components is of utmost importance. One critical element in achieving this cleanliness is the use of dust covers. Among these, the below dust cover plays a pivotal role, providing a barrier against dust, debris, and other contaminants that can compromise the performance and longevity of equipment.

Dust covers are protective coverings made from various materials designed to shield equipment from environmental contaminants. While many may associate dust covers with kitchen appliances or furniture, their application extends far beyond home settings. In industrial contexts, they are essential in safeguarding expensive and sensitive machinery, ensuring that they remain operational and reliable.

Understanding the Importance of a Below Dust Cover

Moreover, below dust covers can also protect against moisture and spills, which are common in many industrial environments. In places where floor washing or spillages occur, having a robust, protective barrier underneath the machinery can help prevent corrosion and damage. This is vital for industries such as pharmaceuticals or food processing, where contamination can lead to significant health risks and financial losses.

bellow dust cover

Additionally, below dust covers contribute to overall workplace safety. Machines that are not adequately protected may pose risks of electrical shorts or fires, especially when dust settles on wiring or electronic components. By utilizing a proper dust cover, companies can significantly reduce these risks, thereby maintaining a safe working environment for employees.

Investing in below dust covers can also lead to cost savings in the long term. Regular cleaning and maintenance of machinery and equipment can be labor-intensive and costly. By minimizing dirt and debris accumulation, businesses can reduce the frequency and extent of maintenance needed. This is not only cost-efficient but also allows for greater operational uptime, as machines may not require as much downtime for cleaning or repairs.

In terms of material, below dust covers can be made from various substances, including plastic, rubber, or specialized fabrics that are designed to endure specific environments. The choice of material largely depends on the context in which the dust cover will be used. For instance, in high-temperature settings, heat-resistant materials would be imperative, while in wet environments, waterproof covers would be preferable.

Furthermore, customization is an essential aspect of below dust covers. Each piece of machinery may have unique dimensions and operational requirements, and thus, off-the-shelf covers may not always fit adequately. Many manufacturers offer custom solutions that cater to specific machinery sizes and applications, ensuring optimal protection.

In conclusion, below dust covers may seem like a simple protective accessory, but they play a crucial role in maintaining the integrity and functionality of machinery and equipment across various industries. By preventing dust and debris accumulation, protecting against moisture and spills, enhancing workplace safety, and providing cost savings through reduced maintenance, these covers are indispensable. Companies that recognize the importance of below dust covers are better positioned to sustain operational efficiency, ensure employee safety, and protect their investment in equipment. Whether in a factory, laboratory, or workshop, the application of below dust covers should be an essential consideration in any comprehensive equipment management strategy.