Understanding Synchronous Belt Pulleys for Efficient Power Transmission Systems

Understanding Synchronous Belt Pulley Systems

Synchronous belt pulley systems are integral to many mechanical and engineering applications, providing a reliable means of power transmission between rotating shafts. These systems are commonly used in machinery requiring precise timing and synchronization, which is essential for efficient operation. This article delves into the design, function, and advantages of synchronous belt pulleys.

What is a Synchronous Belt Pulley?

A synchronous belt pulley, often referred to as a timing pulley, works in conjunction with a synchronous belt (or timing belt). Together, they form a drive mechanism that transmits motion from one pulley to another while maintaining synchronization between the two. Unlike V-belts, synchronous belts feature teeth that engage with corresponding grooves on the pulley, preventing slippage and ensuring that the rotation of one pulley directly correlates with the rotation of the other.

Design and Functionality

The design of synchronous belt pulleys is characterized by specific parameters, including pitch, width, and material. The pitch refers to the distance between the teeth of the pulley, which must match the tooth spacing on the belt for optimal engagement. Width is crucial for power transmission capabilities; a wider belt can handle greater loads. Additionally, the material used for both the pulleys and belts significantly affects durability and performance, with options ranging from rubber composites to reinforced materials.

Functionally, synchronous belt pulleys operate by converting rotational energy from a motor to a mechanical system. When the motor drives the first pulley, the teeth of the synchronous belt mesh with the grooves on this pulley, transmitting motion without any loss of energy through slippage. This direct engagement allows for high efficiency and reduced maintenance compared to other belt drive systems.

Advantages of Synchronous Belt Pulley Systems

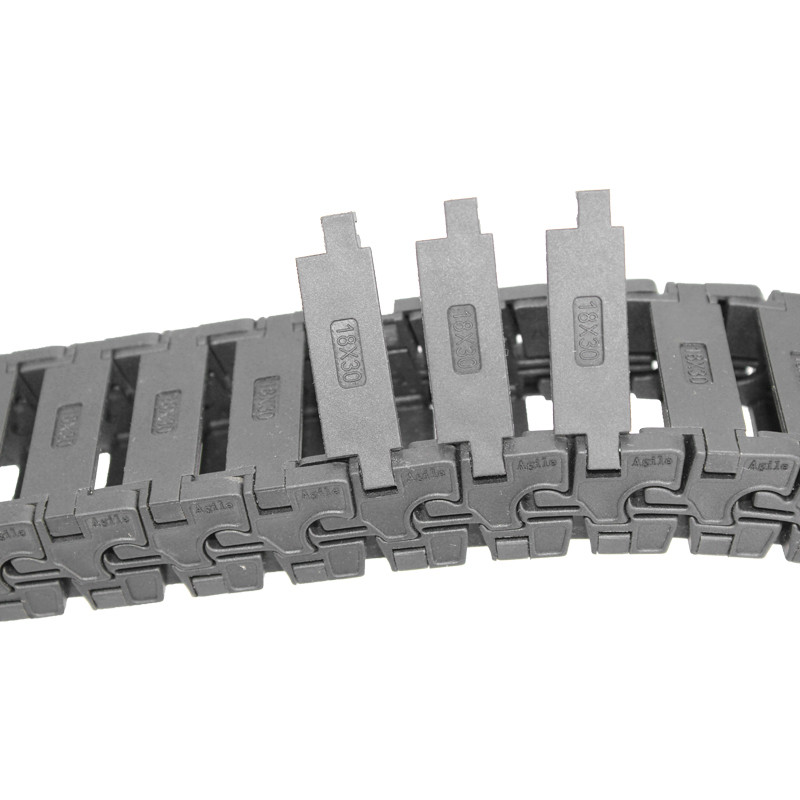

synchronous belt pulley

1. Precise Timing One of the primary advantages of synchronous belt pulley systems is their ability to maintain precise timing between connected components. This feature is critical in applications such as automotive engines, where synchronization between the crankshaft and camshaft is vital for optimal performance.

2. High Efficiency Synchronous belt drives can achieve efficiency levels of up to 98%, making them an excellent choice for applications where minimizing energy loss is essential. The absence of slippage ensures that nearly all input power is converted into output.

3. Low Maintenance These systems typically require less maintenance than traditional belt drives due to their robust design. The enclosed structure helps protect the belt from dirt and debris, reducing wear and extending lifespan.

4. Quiet Operation Synchronous belts operate more quietly than their V-belt counterparts, making them suitable for applications requiring a low noise profile, such as fitness equipment or home appliances.

5. Versatility Synchronous belt pulleys are available in various sizes, designs, and materials, allowing them to be adapted for numerous applications. They can be used in everything from automotive engines to industrial machinery, reflecting their utility across various sectors.

Conclusion

The importance of synchronous belt pulley systems in modern machinery cannot be understated. Their ability to provide synchronized motion, coupled with high efficiency and low maintenance, make them a preferred choice for many engineering applications. Understanding the fundamental principles behind these systems can offer insights into their wide utilization and the continuous innovations in drive technology. Whether in automotive, industrial, or consumer applications, the adaptability and reliability of synchronous belt pulleys ensure their role in the future of mechanical engineering.