Understanding the Functionality and Benefits of Chip Conveyors in Manufacturing Processes

What is a Chip Conveyor?

In manufacturing and machining operations, the efficient removal of metal chips and other debris is crucial to maintaining productivity and ensuring optimal equipment performance. One of the most effective tools for this task is the chip conveyor. But what exactly is a chip conveyor, and how does it work?

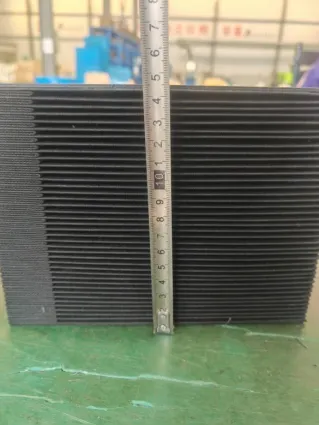

A chip conveyor is a type of equipment specifically designed to transport metal chips, shavings, and other waste products away from machining areas. It plays a vital role in keeping the work environment clean and organized, while also preventing potential equipment damage caused by overload of chips. Chip conveyors are commonly found in industries involving machining, such as metalworking factories, automotive manufacturing, and machining shops.

Types of Chip Conveyors

Chip conveyors can be classified into several types based on their design, method of operation, and application. Some of the most common types include

1. Screw Conveyors These use a rotating helical screw blade to push the metal chips along a trough. They are simple in design, require minimal maintenance, and can handle wet and dry chips efficiently.

2. Drag Chain Conveyors These utilize a chain system that drags the chips through a closed track. Drag chain conveyors are particularly useful for heavy or bulky materials and can effectively manage large quantities of waste.

3. Magnetic Conveyors Employing magnetic forces, these conveyors can attract and transport ferromagnetic chips. This type is advantageous in operations where segregation of magnetic and non-magnetic materials is necessary.

4. Elevator Conveyors These are vertical systems that transport chips upwards. They are ideal for saving floor space and effectively moving chips to a higher level for disposal or further processing.

what is a chip conveyor

Advantages of Chip Conveyors

The use of chip conveyors offers several benefits to manufacturers. Firstly, they help maintain a clean and tidy workspace by facilitating the prompt removal of waste materials. This not only improves workplace safety but also enhances the overall working conditions for employees.

Additionally, chip conveyors contribute to the operational efficiency of machining processes. By automatically removing chips, they reduce the likelihood of machine downtime caused by flooding or jamming. This can lead to a significant increase in productivity, as machines can operate continuously without frequent interruptions for manual chip removal.

In terms of cost-effectiveness, while the initial investment in a chip conveyor may seem high, it can ultimately result in savings over time. By improving the longevity of equipment and minimizing maintenance costs associated with buildup and clogging, businesses can achieve a favorable return on investment.

Selection Considerations

When selecting a chip conveyor, several factors should be taken into account. The type of material being machined, the size of the chips, the volume of waste produced, and the available space are all important considerations. Furthermore, manufacturers should assess the compatibility of the conveyor with existing machinery and workflows to ensure seamless integration.

Durability and maintenance needs are also critical; a well-built conveyor can withstand the rigors of heavy usage and require less frequent repairs. Lastly, accessibility for cleaning and maintenance can greatly affect long-term operational efficiency.

Conclusion

Chip conveyors are essential components of modern manufacturing environments, playing a key role in waste management and production efficiency. By selecting the right type of chip conveyor and ensuring proper integration into existing operations, businesses can boost productivity, enhance workplace safety, and extend the life of their machining equipment. As industries continue to evolve, the importance of efficient waste management solutions like chip conveyors will only grow, marking them as indispensable assets in the manufacturing process.