high temp split loom

Understanding High-Temperature Split Loom A Comprehensive Overview

In today’s technologically advanced world, the ability to effectively manage and protect wiring is essential. As the demand for solutions that offer both durability and flexibility grows, high-temperature split loom emerges as a key player in the realm of cable management. This versatile conduit offers exceptional protection for wires and cables, ensuring they operate efficiently even in challenging environments.

What is High Temperature Split Loom?

High-temperature split loom is a type of protective tubing designed to encase multiple wires and cables. Made from materials that can withstand elevated temperatures, such as polyethylene or nylon, this split loom provides an excellent barrier against heat, abrasion, and other environmental factors that can damage cables. The “split” feature of the loom allows for easy installation, enabling users to simply wrap the tubing around wires without the need for additional tools or connectors.

Applications of High-Temperature Split Loom

High-temperature split loom is utilized in a wide range of applications across various industries. In automotive settings, for instance, it is commonly used to protect wiring harnesses and electrical components, especially in areas near the engine where temperatures can soar. Similarly, in aerospace applications, where reliability is paramount, split loom helps shield delicate wiring from heat and mechanical wear.

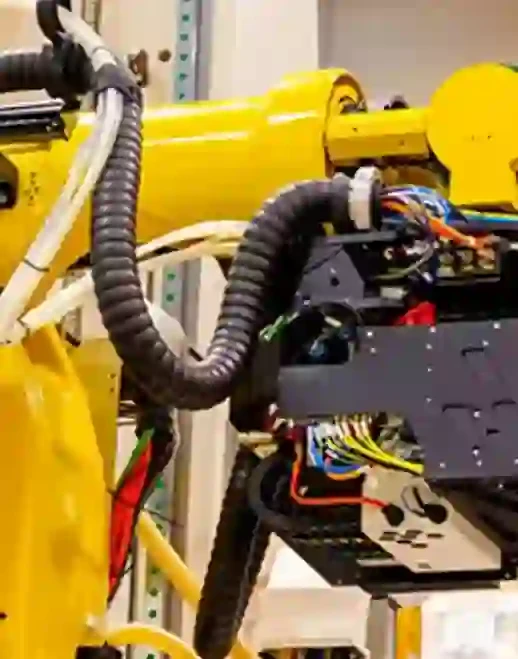

The industrial sector also benefits from high-temperature split loom, as it is used in manufacturing equipment, machinery, and robotics. In environments where exposure to hot surfaces or potential friction is inevitable, using this type of loom ensures that cables remain intact and operational over time.

Benefits of Using High-Temperature Split Loom

high temp split loom

1. Heat Resistance One of the primary advantages of high-temperature split loom is its ability to withstand extreme heat. Unlike standard loom products, which may degrade under high temperatures, the specialized materials used in high-temperature split loom ensure longevity and reliability.

2. Easy Installation The split design allows for straightforward installation and maintenance. Users can quickly wrap the loom around their cables, facilitating repairs and replacements when needed without significant downtime.

3. Durability High-temperature split loom is built to resist impacts, abrasions, and chemicals, making it an ideal choice for environments where cables might be subjected to harsh conditions. This durability extends the lifespan of wiring systems, reducing the need for frequent replacements.

4. Versatility This type of loom is available in various sizes and configurations, accommodating different applications and electrical setups. Whether for residential wiring or heavy-duty industrial systems, there is a suitable option available.

5. Enhanced Safety By protecting wires from excessive heat and physical damage, high-temperature split loom contributes to overall safety. It minimizes the risk of electrical shorts, fires, and other hazards associated with damaged wiring, thus ensuring a safer environment in both residential and industrial settings.

Conclusion

In conclusion, high-temperature split loom is an invaluable solution for anyone looking to enhance the protection of their wiring systems. With its unique ability to withstand extreme conditions, ease of use, and durability, it is well-suited for a variety of applications. As industries continue to evolve and the stakes for reliable electrical systems increase, investing in high-temperature split loom becomes not just an option, but a necessity. By safeguarding cables against heat and damage, users can ensure optimal performance and longevity of their electrical systems.