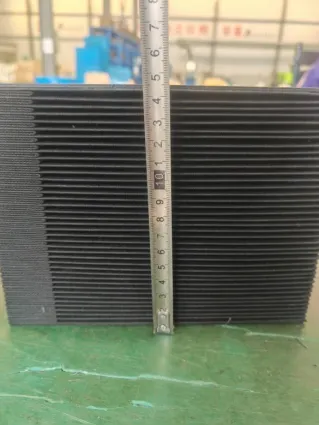

toothed belt drive

Toothed belt drives, often referred to as synchronous belt drives, present a pivotal technology in mechanical power transmission, catering especially to applications that demand precise timing without any slippage. These mechanisms are prevalent in various sectors, ranging from automotive and manufacturing to robotics and aerospace engineering. Their ability to mesh accurately with the pulley grooves, owing to the toothed design, allows them to operate efficiently in high-torque and high-speed environments.

Using toothed belt drives also speaks to a commitment to operational safety. Unlike chain drives, which can stretch over time leading to potential accidents or malfunctions, toothed belts maintain their integrity throughout their operational life. This reliability is especially vital in critical applications where safety cannot be compromised, such as in the aerospace and medical device industries. The adaptability of toothed belt drives adds to their authoritative presence in the market. With various sizes, pitches, and profiles available, they can be tailored to specific application needs. This customization ensures that companies can optimize their machinery for specific tasks, leading to enhanced performance and productivity. Trustworthiness is evident in the widespread adoption of toothed belt drives by reputable manufacturers and industries worldwide. Their proven performance in challenging conditions validates their status as a reliable power transmission solution. Organizations can confidently utilize these belts, knowing that they meet stringent quality and performance standards. In conclusion, toothed belt drives stand out as a technologically advanced, efficient, and reliable solution for modern mechanical systems. Their precise performance, coupled with durability and a low maintenance profile, makes them an ideal choice for industries seeking to enhance their operational efficiency. By investing in toothed belt technology, companies not only improve their productivity but also reinforce their commitment to sustainability and safety in engineering practices.

Using toothed belt drives also speaks to a commitment to operational safety. Unlike chain drives, which can stretch over time leading to potential accidents or malfunctions, toothed belts maintain their integrity throughout their operational life. This reliability is especially vital in critical applications where safety cannot be compromised, such as in the aerospace and medical device industries. The adaptability of toothed belt drives adds to their authoritative presence in the market. With various sizes, pitches, and profiles available, they can be tailored to specific application needs. This customization ensures that companies can optimize their machinery for specific tasks, leading to enhanced performance and productivity. Trustworthiness is evident in the widespread adoption of toothed belt drives by reputable manufacturers and industries worldwide. Their proven performance in challenging conditions validates their status as a reliable power transmission solution. Organizations can confidently utilize these belts, knowing that they meet stringent quality and performance standards. In conclusion, toothed belt drives stand out as a technologically advanced, efficient, and reliable solution for modern mechanical systems. Their precise performance, coupled with durability and a low maintenance profile, makes them an ideal choice for industries seeking to enhance their operational efficiency. By investing in toothed belt technology, companies not only improve their productivity but also reinforce their commitment to sustainability and safety in engineering practices.