cnc reinforced protective rubber custom organ bellow cover

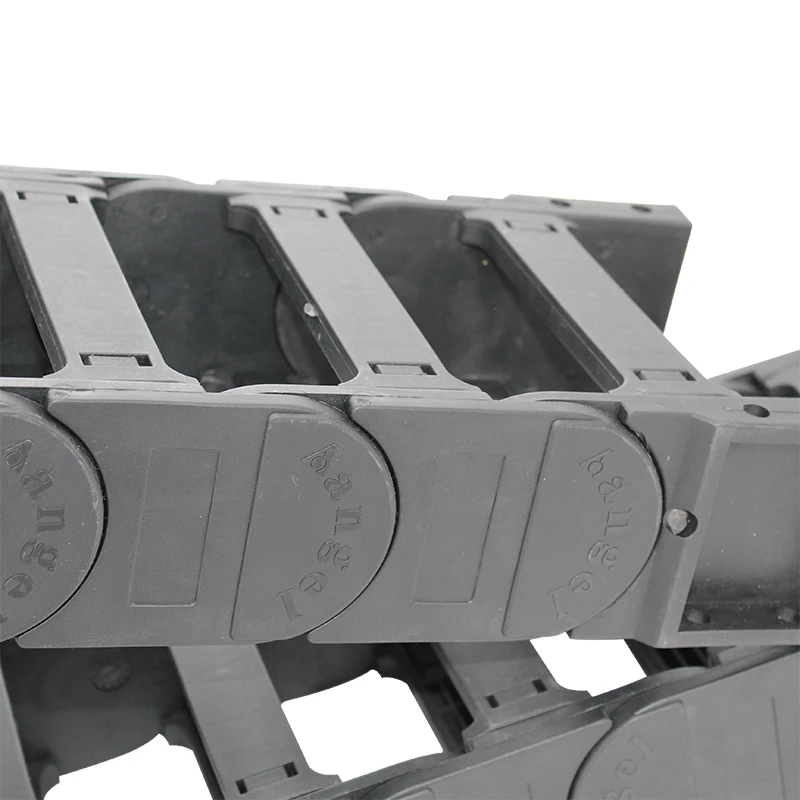

Cylinder bellow covers, integral components in many industrial machinery setups, provide essential protection to machine parts while simultaneously enhancing operational efficiency. They are typically constructed from materials like rubber, polyurethane, or cloth-reinforced composites. Their primary role is to safeguard sensitive parts such as guide rods, screws, and machine ways from dust, debris, and other harmful elements, ensuring a prolonged lifespan and reliable operation.

Trustworthiness is established through rigorous testing and adherence to global safety and quality standards. Reputable manufacturers provide certification that underscores the reliability and durability of their products. Customers can verify these credentials through lab-tested results and adherence to ISO standards, ensuring peace of mind and confidence in their protective solutions. For businesses seeking to invest in cylinder bellow covers, engaging with authorized suppliers who offer comprehensive consultation and support services is advisable. Professional guidance can alleviate typical challenges associated with improper installation or selection, facilitating a seamless integration into existing systems. This proactive approach not only maximizes the utility of the covers but also significantly enhances operational efficiency. Incorporating user feedback and experiences is pivotal in the continuous improvement of cylinder bellow covers. Manufacturers who prioritize customer reviews and real-world performance data stand out, showcasing a commitment to delivering products that genuinely meet the demands of their clientele. This customer-centric approach not only elevates product quality but also builds lasting relationships founded on reliability and trust. Moreover, the evolution of smart technology is beginning to permeate the realm of cylinder bellow covers. Future innovations may see the integration of sensors for real-time monitoring, providing insights into wear and tear and enabling predictive maintenance. This foresight could revolutionize maintenance protocols, highlighting how cylinder bellow covers could become integral to smart factory solutions. In summary, cylinder bellow covers are a pivotal component in safeguarding machinery from environmental hazards while enhancing performance efficiency. Their selection requires a blend of experience and professional expertise to ensure optimal functionality. Backed by authoritative manufacturing practices and steadfast trust in quality, these covers represent a cornerstone in industrial maintenance and machinery longevity.

Trustworthiness is established through rigorous testing and adherence to global safety and quality standards. Reputable manufacturers provide certification that underscores the reliability and durability of their products. Customers can verify these credentials through lab-tested results and adherence to ISO standards, ensuring peace of mind and confidence in their protective solutions. For businesses seeking to invest in cylinder bellow covers, engaging with authorized suppliers who offer comprehensive consultation and support services is advisable. Professional guidance can alleviate typical challenges associated with improper installation or selection, facilitating a seamless integration into existing systems. This proactive approach not only maximizes the utility of the covers but also significantly enhances operational efficiency. Incorporating user feedback and experiences is pivotal in the continuous improvement of cylinder bellow covers. Manufacturers who prioritize customer reviews and real-world performance data stand out, showcasing a commitment to delivering products that genuinely meet the demands of their clientele. This customer-centric approach not only elevates product quality but also builds lasting relationships founded on reliability and trust. Moreover, the evolution of smart technology is beginning to permeate the realm of cylinder bellow covers. Future innovations may see the integration of sensors for real-time monitoring, providing insights into wear and tear and enabling predictive maintenance. This foresight could revolutionize maintenance protocols, highlighting how cylinder bellow covers could become integral to smart factory solutions. In summary, cylinder bellow covers are a pivotal component in safeguarding machinery from environmental hazards while enhancing performance efficiency. Their selection requires a blend of experience and professional expertise to ensure optimal functionality. Backed by authoritative manufacturing practices and steadfast trust in quality, these covers represent a cornerstone in industrial maintenance and machinery longevity.