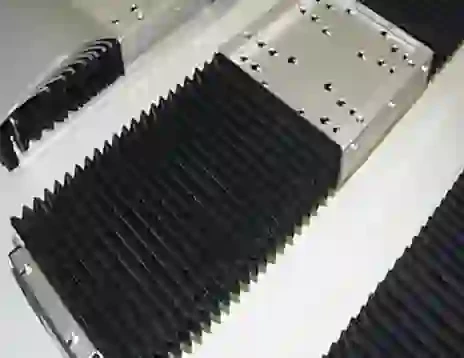

cnc bellows

The Importance of CNC Bellows in Modern Manufacturing

In the world of modern manufacturing, precision and protection are paramount. One component that plays a crucial role in ensuring both of these attributes is the CNC bellows. CNC bellows, short for Computer Numerical Control bellows, are protective covers made from flexible materials, typically used in machinery to shield moving parts from dust, debris, and other environmental contaminants.

The Importance of CNC Bellows in Modern Manufacturing

Moreover, CNC bellows are designed to accommodate the specific movements of the machinery they protect. The flexibility of the materials used allows these bellows to extend and retract seamlessly as the machinery operates. This adaptability is particularly crucial for CNC machines, which often involve complex movements and operations. By employing custom-designed bellows, manufacturers can ensure that their CNC machines remain efficient and effective, reducing maintenance time and costs.

cnc bellows

The manufacturing process for CNC bellows is itself a testament to modern engineering capabilities. Using CNC technology, bellows can be manufactured to precise specifications, ensuring that they fit perfectly within the machinery they are designed for. This precision eliminates gaps where contaminants might enter while also ensuring that the bellows do not impede the machine’s operation. The ability to produce custom-sized bellows means that they can be employed across a wide range of industries, from automotive to aerospace, and everything in between.

Additionally, CNC bellows can also play a vital role in controlling fluids and gases within mechanical systems. In hydraulic systems, for instance, bellows can function as a sealant, preventing leaks and ensuring that the system functions correctly. This capability is essential for maintaining safety and efficiency in various industrial applications.

Furthermore, the materials used to create CNC bellows are often resistant to extreme temperatures and chemicals, making them suitable for harsh environments. Whether it’s exposure to high heat, caustic substances, or freezing conditions, CNC bellows are engineered to withstand such challenges without compromising their effectiveness. This resilience adds a layer of durability and reliability that manufacturers can depend on.

In conclusion, CNC bellows are a vital component in the safeguarding of modern machinery. Their ability to protect against contaminants, accommodate complex movements, and maintain the integrity of mechanical systems makes them indispensable in various manufacturing environments. As industries continue to evolve and place higher demands on machinery, the role of CNC bellows will only become more significant. Their integration into manufacturing processes not only contributes to the longevity of the equipment but also promotes efficiency and productivity, hallmarks of successful modern manufacturing practices. As technology advances, the design and application of CNC bellows will also likely evolve, further enhancing their importance in various industrial sectors.