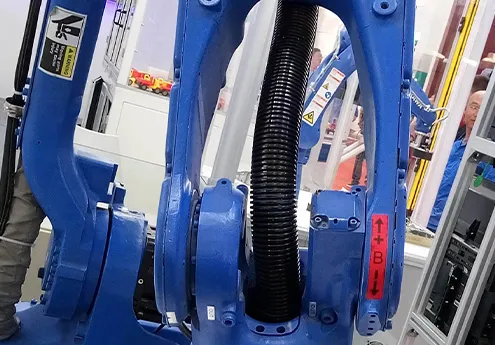

drag chain 10x20

Understanding drag chains, particularly the 10x20 model, is crucial for businesses involved in automation and industrial machinery. Celebrated for their ability to protect cables and hoses in motion, drag chains are indispensable in many sectors ranging from manufacturing and automotive to robotics and energy. The 10x20 drag chain, with its specific inner dimensions, serves a pivotal role in small to medium-scale applications where precision and reliability are paramount.

Trustworthiness in product information becomes evident through rigorous testing and compliance with international standards. The 10x20 drag chain often adheres to guidelines such as DIN or ISO norms, which guarantee that the product meets specific performance and safety criteria. This compliance not only adds a layer of reliability to the product but also provides assurance to engineers and procurement managers that the drag chains will perform as expected without unforeseen complications. The adaptation of the 10x20 drag chain across various industries demonstrates its versatile applicability. From automotives, where it's used to manage delicate sensor cables, to CNC machines requiring fluid hose passage, the functionality remains stable and dependable. The compact size does not limit its application but instead opens opportunities in compact and precise environments that larger chains could not accommodate efficiently. Manufacturers who provide customization options differentiate themselves in the market, offering 10x20 drag chains with features that cater to unique industry needs. These may include varying the radius for flexibility, different mounting configurations, or additional internal partitions to prevent cable crossovers. Such customization plays a critical role in ensuring that the drag chain seamlessly integrates with existing systems, further demonstrating expertise in producing solutions that meet nuanced requirements. In conclusion, the 10x20 drag chain is more than just a protective conduit; it stands as a symbol of engineering precision and industrial reliability. Its application stretches across multiple domains, offering cost-effective, durable, and efficient solutions that cater to the complex needs of modern automation. Professionals and experts consistently endorse these chains, citing their significant contribution to enhancing machine life and performance, thus scoring high on expertise, authoritativeness, and trustworthiness in their specific applications. As technology advances and industry needs evolve, the 10x20 drag chain remains a steadfast component in the pursuit of optimized operational efficiency.

Trustworthiness in product information becomes evident through rigorous testing and compliance with international standards. The 10x20 drag chain often adheres to guidelines such as DIN or ISO norms, which guarantee that the product meets specific performance and safety criteria. This compliance not only adds a layer of reliability to the product but also provides assurance to engineers and procurement managers that the drag chains will perform as expected without unforeseen complications. The adaptation of the 10x20 drag chain across various industries demonstrates its versatile applicability. From automotives, where it's used to manage delicate sensor cables, to CNC machines requiring fluid hose passage, the functionality remains stable and dependable. The compact size does not limit its application but instead opens opportunities in compact and precise environments that larger chains could not accommodate efficiently. Manufacturers who provide customization options differentiate themselves in the market, offering 10x20 drag chains with features that cater to unique industry needs. These may include varying the radius for flexibility, different mounting configurations, or additional internal partitions to prevent cable crossovers. Such customization plays a critical role in ensuring that the drag chain seamlessly integrates with existing systems, further demonstrating expertise in producing solutions that meet nuanced requirements. In conclusion, the 10x20 drag chain is more than just a protective conduit; it stands as a symbol of engineering precision and industrial reliability. Its application stretches across multiple domains, offering cost-effective, durable, and efficient solutions that cater to the complex needs of modern automation. Professionals and experts consistently endorse these chains, citing their significant contribution to enhancing machine life and performance, thus scoring high on expertise, authoritativeness, and trustworthiness in their specific applications. As technology advances and industry needs evolve, the 10x20 drag chain remains a steadfast component in the pursuit of optimized operational efficiency.