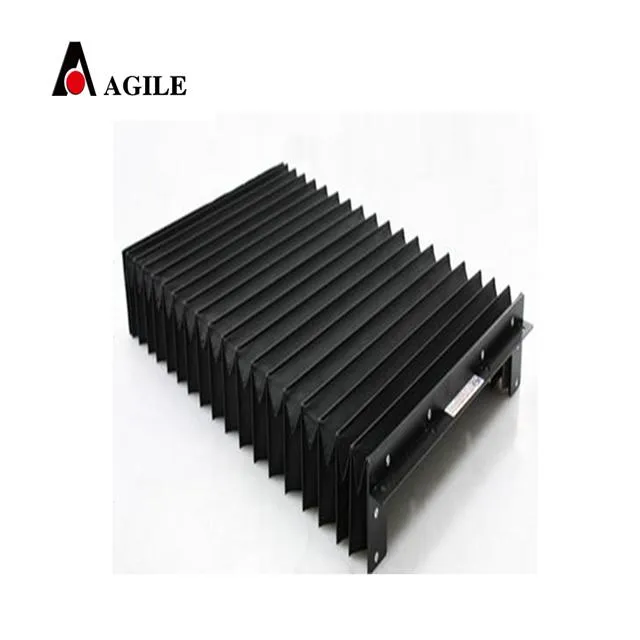

reinforced drag chain

The evolution of industrial automation has brought numerous innovations to streamline processes, and one unsung hero at the core of these advancements is the reinforced drag chain. More than just an accessory, it is integral to ensuring seamless operations in high-stakes environments. Achieving optimal performance from machinery heavily relies on this robust component, which not only secures cables and hoses but also enhances their reliability and longevity.

From a technical perspective, the expertise involved in manufacturing these chains can’t be overstated. Advanced engineering techniques like finite element analysis (FEA) are employed to predict performance under various conditions, making sure each product delivered is optimized for energy efficiency and mechanical resilience. Such meticulous attention to detail ensures that the chains can support dynamic applications where high speeds and complex movements are prevalent. For those seeking to enhance the efficiency and reliability of machinery, selecting premium reinforced drag chains is a strategic investment. They offer lasting benefits such as reduced risk of operational failures, enhanced safety due to minimized cable clutter, and improved overall aesthetic of the machinery setup. These advantages align with broader environmental and economic goals by fostering sustainable practices through durable and resource-efficient solutions. Investing in reinforced drag chains is not merely about acquiring a product but embracing a comprehensive approach to efficient cable management. Industry veterans recommend consulting with manufacturers or technical advisors to select the best-fit solution tailored for specific needs. This ensures that every aspect of your operational requirements is accounted for, maximizing the value derived from this essential component. In conclusion, reinforced drag chains are a testament to engineering prowess and the pursuit of operational excellence. With their undeniable impact on machinery performance and reliability, they are indispensable in today's fast-paced, technology-driven industrial landscape. Their contribution transcends mere functionality, embodying a synthesis of experience, expertise, authoritative design, and trustworthiness—all essential for advancing industrial capabilities.

From a technical perspective, the expertise involved in manufacturing these chains can’t be overstated. Advanced engineering techniques like finite element analysis (FEA) are employed to predict performance under various conditions, making sure each product delivered is optimized for energy efficiency and mechanical resilience. Such meticulous attention to detail ensures that the chains can support dynamic applications where high speeds and complex movements are prevalent. For those seeking to enhance the efficiency and reliability of machinery, selecting premium reinforced drag chains is a strategic investment. They offer lasting benefits such as reduced risk of operational failures, enhanced safety due to minimized cable clutter, and improved overall aesthetic of the machinery setup. These advantages align with broader environmental and economic goals by fostering sustainable practices through durable and resource-efficient solutions. Investing in reinforced drag chains is not merely about acquiring a product but embracing a comprehensive approach to efficient cable management. Industry veterans recommend consulting with manufacturers or technical advisors to select the best-fit solution tailored for specific needs. This ensures that every aspect of your operational requirements is accounted for, maximizing the value derived from this essential component. In conclusion, reinforced drag chains are a testament to engineering prowess and the pursuit of operational excellence. With their undeniable impact on machinery performance and reliability, they are indispensable in today's fast-paced, technology-driven industrial landscape. Their contribution transcends mere functionality, embodying a synthesis of experience, expertise, authoritative design, and trustworthiness—all essential for advancing industrial capabilities.