synchronous belt vs v belt

Synchronous Belt vs. V-Belt A Comprehensive Comparison

When it comes to mechanical power transmission systems, two common types of belts are frequently compared synchronous belts and V-belts. Both serve the purpose of transferring power between various components in machines and engines, yet they possess distinct characteristics that make them suitable for different applications. Understanding the differences between these two belt types can help engineers and designers make informed decisions when selecting the right power transmission solution.

Design and Structure

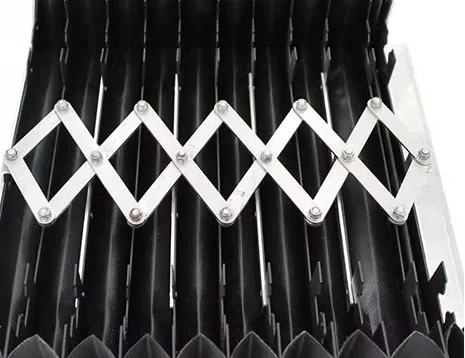

Synchronous belts, often referred to as timing belts, are constructed with a series of evenly spaced teeth along their inner surface. This design allows them to mesh perfectly with corresponding teeth on pulleys, preventing slippage and ensuring precise timing. Synchronous belts are typically made from a combination of rubber and reinforced materials like fiberglass or aramid to enhance strength and durability.

In contrast, V-belts have a trapezoidal cross-section, allowing them to sit snugly in the grooves of V-shaped pulleys. This design provides a great deal of friction, enabling V-belts to grip the pulleys tightly without slipping. V-belts are generally made from rubber, sometimes reinforced with additional materials, but they lack the teeth that characterize synchronous belts.

Performance and Efficiency

One of the most significant advantages of synchronous belts is their ability to maintain precise timing between pulleys. This precise engagement is crucial in applications where synchronization is critical, such as in automotive engines or CNC machines. The absence of slippage means that synchronous belts can achieve better efficiency and transfer more power with less energy loss.

synchronous belt vs v belt

On the other hand, V-belts are known for their versatility and ease of installation. They can handle slight misalignments between pulleys, making them suitable for applications where perfect alignment is challenging. V-belts are also capable of transmitting a significant amount of power, particularly in older machinery, making them a popular choice in various industrial applications.

Lifespan and Maintenance

In terms of lifespan, synchronous belts often have a longer operational life if properly maintained and used within their designed limits. The teeth on the synchronous belts minimize wear and tear, whereas V-belts may require more frequent replacements due to their tendency to wear down and stretch over time. Additionally, V-belts may require periodic tension adjustments to prevent slipping, further complicating their maintenance.

Cost Considerations

Cost is another factor to consider when choosing between synchronous belts and V-belts. Synchronous belts tend to be more expensive upfront due to their specialized materials and design. However, the longer lifespan and lower maintenance requirements can lead to cost savings over time. V-belts, while generally less expensive, may incur higher long-term costs due to more frequent replacements and potential efficiency losses.

Conclusion

Both synchronous belts and V-belts have their advantages and disadvantages, making them suitable for different applications. Synchronous belts excel in environments where timing precision is paramount, while V-belts offer versatility and ease of installation. The choice between these two types of belts ultimately depends on the specific requirements of the application, including factors such as alignment, power transmission efficiency, maintenance needs, and budget constraints. By understanding these differences, engineers can make informed choices that enhance the performance and reliability of their systems.