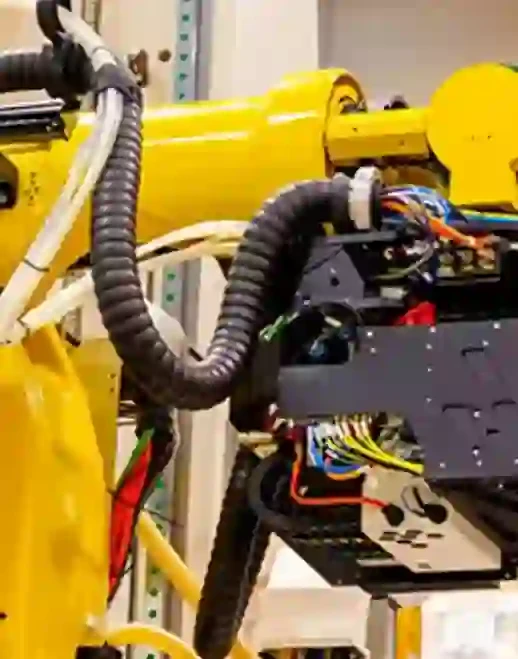

screw type chip conveyor

The Advantages and Applications of Screw Type Chip Conveyors

In modern manufacturing environments, efficient handling of metal chips and shavings is essential for maintaining productivity and ensuring workplace safety. Among the various solutions available for chip management, screw type chip conveyors have emerged as one of the most effective and reliable options. This article explores the advantages, design features, and applications of screw type chip conveyors in industrial settings.

What is a Screw Type Chip Conveyor?

A screw type chip conveyor, also known as a screw conveyor or auger conveyor, is a mechanical device used to transport metal chips, shavings, and other particulate materials from one location to another. It utilizes a rotating helical screw—often referred to as an auger—inserted within a tube or trough. As the screw rotates, it moves the chips along the length of the conveyor, allowing for efficient collection and disposal.

Advantages of Screw Type Chip Conveyors

1. Versatility Screw type chip conveyors are versatile and can effectively handle various types of chips, including aluminum, steel, and plastic. This makes them suitable for different machining processes, such as milling, turning, and grinding.

2. Space Efficiency These conveyors can be installed in tight spaces due to their compact design. They can be oriented horizontally, vertically, or at an incline, allowing for flexible installation in diverse manufacturing layouts.

3. Continuous Operation Unlike some conveyor systems that require frequent stops for maintenance or cleaning, screw type conveyors are designed for continuous operation. Their robust design minimizes the risk of blockages, ensuring a consistent flow of materials.

4. Reduced Noise Levels Screw conveyors operate relatively quietly compared to other material handling systems, helping to maintain a safer and more pleasant working environment.

5. Low Maintenance Due to their simple design and rugged construction, screw type chip conveyors require minimal maintenance. Regular inspections and lubrication are typically sufficient to ensure reliable operation.

6. Customization Options Manufacturers can tailor screw conveyor systems to meet specific needs, including modifications in length, diameter, and material type. This customization helps to accommodate different production processes and chip characteristics.

Design Features

Screw type chip conveyors incorporate several design features that enhance their functionality

screw type chip conveyor

- Durable Materials They are often constructed from materials that resist wear and corrosion, such as stainless steel or hardened carbon steel, ensuring a long lifespan even with heavy use.

- Variable Speed Drives Many screw conveyors are equipped with variable speed drives that allow users to adjust the speed of the auger based on the type and volume of chips generated, optimizing the collection process.

- Integrated Filtering Systems Some models come with integrated filtering systems that can separate fine particles from larger chips, helping to maintain the quality of the collected material for recycling or disposal.

- Efficient Discharge Mechanisms The design often includes effective discharge mechanisms to direct chips to the appropriate collection points or recycling bins, minimizing manual handling.

Applications in Industry

Screw type chip conveyors are widely used in various industries, including

- Metalworking In machining operations where metal chips are produced, screw conveyors efficiently transport these chips away from machines, reducing workspace clutter and improving safety.

- Automotive Manufacturing They play a crucial role in automotive assembly plants, where machining processes generate large volumes of waste material.

- Aerospace and Defense Given the precision required in aerospace manufacturing, screw conveyors help manage chips generated during machining, ensuring an organized and efficient workflow.

- Recycling Facilities In recycling applications, these conveyors assist in the separation and transport of recyclable metal waste, contributing to environmental sustainability.

Conclusion

Screw type chip conveyors are indispensable tools in modern manufacturing, providing efficient, reliable, and flexible chip management solutions. Their ability to handle various materials in confined spaces while maintaining operational efficiency makes them a preferred choice for industries focused on productivity and safety. As technology advances, these conveyors will continue to evolve, incorporating innovations that further enhance their functionality and integration into smart manufacturing environments. With their many advantages, screw type chip conveyors will remain a key component of effective waste management systems in industrial settings.