CNC Machine Bellows Covers for Enhanced Protection and Performance Efficiency

CNC Machine Bellow Covers Essential Components for Precision Engineering

CNC (Computer Numerical Control) machines are pivotal in modern manufacturing, providing exceptional precision and repeatability in machining processes. As these machines operate at high speeds and with intricate components, protecting them is crucial for maintaining performance and prolonging lifespan. One essential element of this protection is the use of bellow covers.

Understanding Bellow Covers

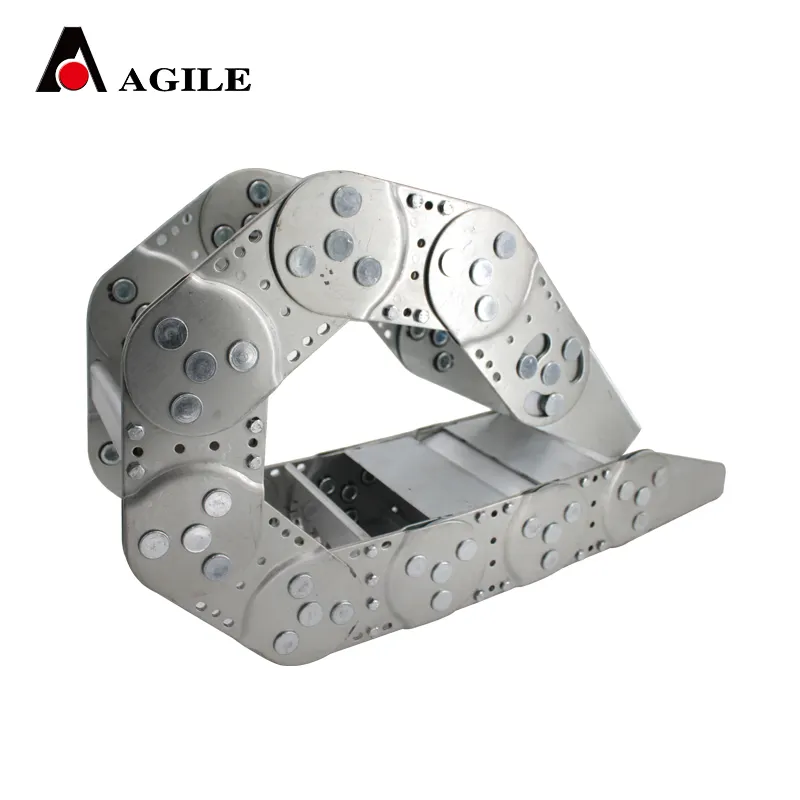

Bellow covers are flexible, protective barriers that shield various moving parts of CNC machines from debris, coolant, dust, and other contaminants. They are typically made from materials such as rubber, polyurethane, or fabric and are designed to withstand the harsh conditions often found in manufacturing environments.

The primary function of bellow covers is to prevent foreign particles from entering critical areas of the machine, such as the spindle and linear guideways. This protection ensures that moving parts can operate smoothly, reducing wear and tear that might otherwise lead to premature machine failure.

Types of Bellow Covers

Bellow covers come in various shapes and sizes, tailored to the specific requirements of different CNC machines. Some common types of bellow covers include

1. Round Bellows Often used for vertical applications, round bellows can cover the movement of components like spindles and screws, providing flexibility and protection against dust and chips.

2. Square and Rectangular Bellows These are designed for linear motion applications, such as slide guides or machine tables. Their flat, rigid design helps maintain their shape while providing adequate protection.

Each type of bellow cover has its advantages and can be selected based on the specific needs of the CNC machine and its operating environment.

cnc machine bellow covers

Benefits of Using Bellow Covers

1. Enhanced Protection The primary benefit of bellow covers is the protection they offer. They prevent contaminants from entering machine parts, which is vital for maintaining precision and performance. In environments where metal shavings, coolant, and dust are prevalent, bellow covers play an essential role in safeguarding machinery.

2. Reduced Maintenance Costs By preventing damage caused by debris, bellow covers can significantly reduce maintenance requirements. Machines can operate longer without the need for costly repairs, leading to lower operational costs over time.

3. Improved Safety Bellow covers also contribute to workplace safety by containing potentially hazardous substances and sharp objects. This containment minimizes the risk of accidents, ensuring a safer working environment for employees.

4. Extended Equipment Lifespan By providing robust protection against wear and tear, bellow covers can extend the useful life of CNC machines. This longevity translates to better ROI for manufacturing companies as they can rely on their equipment for longer periods.

5. Flexibility and Versatility The flexibility of bellow covers allows them to accommodate various movements within the machine. This adaptability is crucial in complex machining operations where precision is key.

Choosing the Right Bellow Cover

Selecting the appropriate bellow cover for a CNC machine involves several considerations. First, it is essential to understand the specific application and the environment in which the machine operates. Factors such as temperature, movement type, and the presence of chemicals or coolant can all influence the choice of bellow cover material.

Furthermore, consulting with manufacturers or suppliers who specialize in CNC machine accessories can provide valuable insights. They can recommend the best options based on industry standards and customer experiences.

Conclusion

In the world of CNC machining, every component matters, and bellow covers are no exception. These protective barriers enhance the performance and longevity of machines, contributing to efficient manufacturing processes. As technology continues to evolve, investing in high-quality bellow covers will remain a fundamental practice for businesses striving for excellence in precision engineering. Whether you are looking to shield your machinery from harsh environments or prolong the life of your equipment, bellow covers are a smart choice that benefits both productivity and safety in the modern manufacturing landscape.