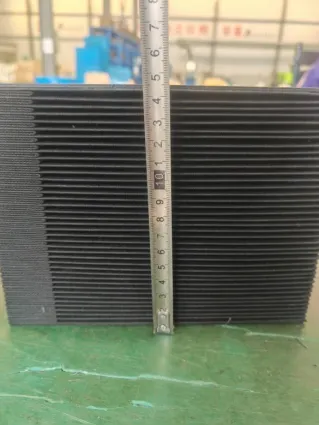

plastic cable chain

The Importance of Plastic Cable Chains in Modern Industry

In today's fast-paced industrial environment, efficiency and reliability are paramount. One of the essential components that facilitate smooth and organized operations in various sectors is the plastic cable chain. These innovative devices are engineered to manage and protect cables, hoses, and wires, becoming indispensable in applications ranging from robotics to automation and beyond.

Plastic cable chains, also known as energy chains, serve as protective housing for moving cables. They are particularly critical in environments where cables can be exposed to wear and tear, friction, and the potential for snagging. This is common in machinery with moving parts that operate in dynamic conditions, such as CNC machines, conveyor systems, and robotic arms. By keeping cables organized and protected, these chains significantly reduce the risk of damage and downtime, thus enhancing overall operational efficiency.

One of the most significant advantages of plastic cable chains is their lightweight nature. Unlike traditional steel chains, plastic variants are not only lighter but also resistant to various environmental factors such as corrosion and extreme temperatures. This attribute makes them suitable for a wide range of applications, including food processing, where sanitation and cleanliness are critical, and electronics manufacturing, where precision and reliability are key.

The design of plastic cable chains is another notable feature that contributes to their growing popularity. They come in various sizes, shapes, and configurations, allowing for customization based on specific requirements. Manufacturers can choose from open or closed designs, depending on whether they require easy access to the cables or ultimate protection. Furthermore, many modern plastic cable chains are designed for easy installation and maintenance, allowing manufacturers to minimize downtime and streamline operations.

plastic cable chain

Plastic cable chains also provide flexibility and adaptability in increasingly automated environments. As technologies evolve, so do the ways in which machines operate. Modular systems and reconfigurable robots require adaptable cable management solutions, and plastic cable chains fit the bill perfectly. They can be easily adjusted and rerouted, accommodating changes in machinery layout or functionality without the need for extensive reinstallation.

In addition to their mechanical benefits, plastic cable chains contribute to safety in the workplace. By organizing and enclosing cables, they minimize tripping hazards and reduce the chances of accidental disconnections. This not only protects workers but also safeguards sensitive equipment from potential damage caused by errant cables.

Environmental considerations are also driving the adoption of plastic cable chains. Many manufacturers are now producing these components from recyclable materials, aligning with modern sustainability goals and reducing the carbon footprint of operations. As industries increasingly focus on eco-friendly practices, the demand for sustainable cable management solutions is on the rise.

In summary, plastic cable chains are a vital component in modern industrial applications. Their lightweight design, versatility, ease of maintenance, and contribution to workplace safety make them an essential choice for businesses seeking to enhance operational efficiency and reliability. As industries continue to evolve and embrace automation, the role of plastic cable chains will undoubtedly grow, making them a crucial element in the future of manufacturing and engineering.