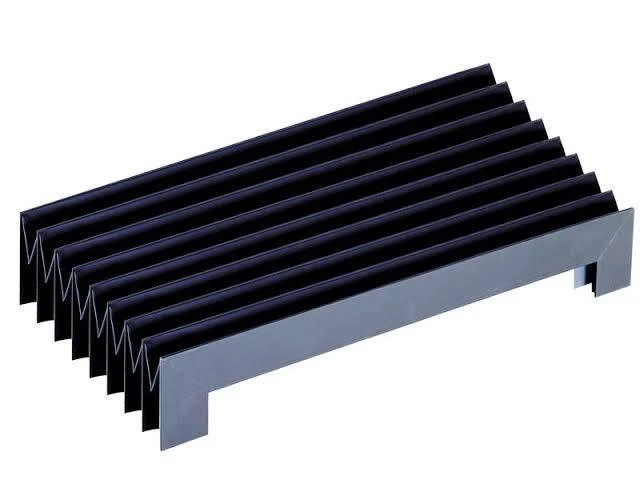

mini drag chain

For industrial processes that demand high efficiency and reliability, choosing the right material handling equipment is pivotal. Drag chain conveyors, known for their robustness and adaptability, have gained traction across various sectors such as manufacturing, mining, and grain processing. With decades of history and continuous advancements, they are renowned for their exceptional performance in transporting bulk materials.

For businesses seeking to improve operational efficiency while safeguarding against equipment failure, drag chain conveyors represent a sound investment. Their resilience reduces the frequency of repairs and replacements, translating into cost savings over time. The conveyance method also ensures that even temperature-sensitive or fragile products are transported without compromise, enhancing product quality and reducing waste. To solidify their position as an authoritative choice in conveyor systems, drag chain conveyors boast a track record backed by real-world applications. Companies that have implemented these systems report not only improvements in efficiency and safety but also a boost in overall productivity. Customer testimonials consistently highlight the conveyors' reliability and ease of maintenance as key benefits. Sourcing from reputable manufacturers is crucial when investing in drag chain conveyors. Trusted manufacturers maintain stringent quality control processes and offer comprehensive support, from customization and installation to after-sales service. This commitment to quality and customer satisfaction enhances the trustworthiness of the equipment and ensures that it meets specific industry demands. For businesses navigating the complexities of material handling, selecting the right equipment is paramount. Drag chain conveyors, with their proven track record and advanced features, stand out as an optimal solution combining efficiency, reliability, and adaptability. Investing in these systems not only solves immediate logistical challenges but also sets a foundation for long-term operational success.

For businesses seeking to improve operational efficiency while safeguarding against equipment failure, drag chain conveyors represent a sound investment. Their resilience reduces the frequency of repairs and replacements, translating into cost savings over time. The conveyance method also ensures that even temperature-sensitive or fragile products are transported without compromise, enhancing product quality and reducing waste. To solidify their position as an authoritative choice in conveyor systems, drag chain conveyors boast a track record backed by real-world applications. Companies that have implemented these systems report not only improvements in efficiency and safety but also a boost in overall productivity. Customer testimonials consistently highlight the conveyors' reliability and ease of maintenance as key benefits. Sourcing from reputable manufacturers is crucial when investing in drag chain conveyors. Trusted manufacturers maintain stringent quality control processes and offer comprehensive support, from customization and installation to after-sales service. This commitment to quality and customer satisfaction enhances the trustworthiness of the equipment and ensures that it meets specific industry demands. For businesses navigating the complexities of material handling, selecting the right equipment is paramount. Drag chain conveyors, with their proven track record and advanced features, stand out as an optimal solution combining efficiency, reliability, and adaptability. Investing in these systems not only solves immediate logistical challenges but also sets a foundation for long-term operational success.