1 1 2 split loom

The Versatility of Split Loom A Closer Look at 1% 201% 202%

The Versatility of Split Loom A Closer Look at 1% 201% 202%

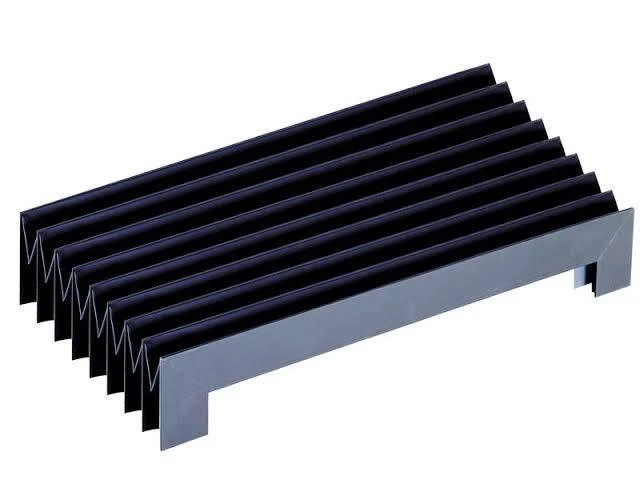

Split loom tubing is characterized by its unique design—made of a flexible plastic material, it features a longitudinal slit that allows for easy placement around groups of wires without the need for additional connectors. The 1% measurement often refers to the diameter or the wall thickness of the tubing, which is critical for ensuring that it fits snugly around the cables it is meant to protect. The sturdiness of 1% split loom makes it suitable for industrial uses, where exposure to significant wear and tear is commonplace.

1 1 2 split loom

Moving to the 201% split loom, its designation implies a higher capacity for accommodating larger bundles of cables. This version is particularly useful in settings where a plethora of wires are present, such as data centers or broadcast studios, ensuring that these cables remain organized and protected from damage or signal interference. Additionally, 201% split loom helps to maintain a clean aesthetic in complex wiring installations.

Lastly, the 202% split loom offers modifications that respond to specific industry demands. For instance, the material might be enhanced with features like UV resistance, making it ideal for outdoor use. This additional protection allows cables to withstand environmental threats and enhances their longevity, making it a reliable choice for landscaping projects or outdoor events.

In conclusion, split loom tubing is not just a necessity; it is a versatile solution for a variety of cable management needs. The distinctions among 1% 201% and 202% versions cater to different specifications, ensuring that users can select the ideal product according to their requirements. Whether protecting wires in a bustling factory or organizing cables in a home office, split loom provides durability, flexibility, and efficiency, proving itself to be an indispensable tool in modern wiring solutions.