split wire loom tubing

The Benefits and Uses of Split Wire Loom Tubing

Wire management is an often-overlooked aspect of both commercial and residential projects. Properly organized wires not only enhance the aesthetic appeal of spaces but also significantly reduce the risk of electrical hazards. One of the most effective solutions for managing and protecting wires is the use of split wire loom tubing. This article will explore what split wire loom tubing is, its benefits, and its various applications.

What is Split Wire Loom Tubing?

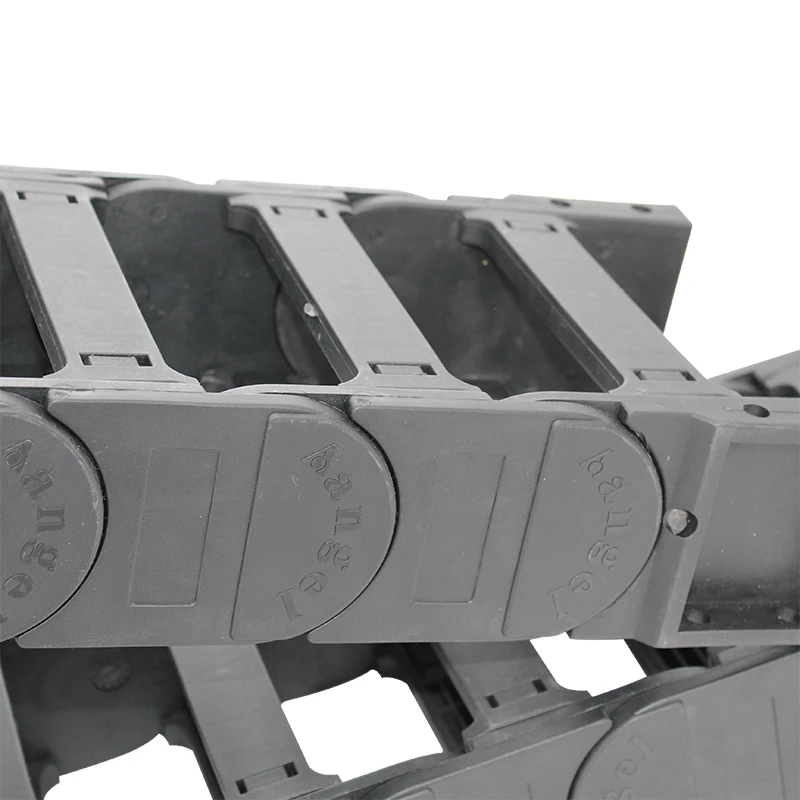

Split wire loom tubing is a type of conduit that provides protection and organization for electrical wires. Made from durable materials, such as polyethylene or polyethylene terephthalate (PET), this tubing features a longitudinal split along its length. This design allows users to easily insert and remove wires as needed, making it a flexible solution for wire management.

Benefits of Split Wire Loom Tubing

1. Protection Against Environmental Factors One of the primary advantages of using split wire loom tubing is its ability to shield wires from environmental factors. Whether it's moisture, dust, or abrasion, the tubing acts as a barrier, prolonging the life of the wires it encases. This is particularly important in outdoor settings where wires are exposed to harsh conditions.

2. Organized Appearance Aesthetics matter, especially in professional environments. Split wire loom tubing provides a neat and tidy appearance to bundled wires, making it easier to identify connections and track systems. This visual organization can make troubleshooting simpler and reduce the time needed for maintenance.

3. Reduced Risk of Damage Wires that are not properly secured are susceptible to wear and tear. By using split wire loom tubing, you can minimize the risk of frayed wires or shorts due to accidental pulls or tangling. This is especially valuable in high-traffic areas or applications where wires might be subject to movement.

split wire loom tubing

4. Electrical Safety Insulation is crucial when it comes to electrical wires. Split wire loom tubing not only helps organize wires but also adds a layer of insulation. This can aid in preventing electrical shocks and short circuits, thereby enhancing the overall safety of the installation.

Applications of Split Wire Loom Tubing

1. Automotive Uses In the automotive industry, split wire loom tubing is commonly used to protect the wiring harnesses of vehicles. This application is vital due to the exposure of wires to heat, moisture, and mechanical stresses. Utilizing this tubing helps maintain the integrity of wiring throughout the vehicle's lifespan.

2. Home and Office In residential and commercial environments, split wire loom tubing is often used for home theater systems, computer setups, and office equipment. By organizing the wires associated with these devices, users can minimize clutter and enhance both safety and functionality.

3. Industrial Applications Many industrial applications benefit from the use of split wire loom tubing. Factories often have extensive wiring that controls machinery; using loom tubing helps to protect these critical wires from oils, chemicals, and abrasion.

4. DIY Projects For hobbyists and DIY enthusiasts, split wire loom tubing is an essential tool. Whether you are building custom electronics or managing wires in home renovations, this versatile product can help you keep your projects organized and safe.

Conclusion

Split wire loom tubing is a simple yet effective solution for wire management that brings numerous benefits. Its protective qualities, organizational features, and versatility make it an excellent choice for a wide range of applications—ranging from automotive and industrial uses to home and office environments. Investing in good quality split wire loom tubing can not only enhance security and durability but also lead to a more aesthetically pleasing workspace. Therefore, whether you're a professional or a DIY enthusiast, considering split wire loom tubing for your next project could be a step towards a neater and safer wire management solution.