wood chip conveyor

Wood Chip Conveyor An Essential Component in Wood Processing Industries

In the wood processing industry, efficiency and productivity are paramount. One of the key elements contributing to these factors is the wood chip conveyor. This essential machinery is designed to transport wood chips, sawdust, and other wood remnants seamlessly through various stages of production, from the initial processing to the final product output.

Wood chip conveyors come in various designs and configurations, tailored to meet the specific needs of wood processing facilities. The primary function of these conveyors is to transfer wood chips from one location to another while minimizing waste and maximizing speed. This is particularly important in large-scale operations where handling vast quantities of wood materials is routine.

One of the most common types of wood chip conveyors is the belt conveyor. Known for its durability and reliability, a belt conveyor utilizes a continuous loop of material to carry wood chips along a predetermined path. This design can accommodate heavy loads and is capable of operating over long distances, making it ideal for expansive facilities. Additionally, belt conveyors can be customized with features like adjustable speeds and incline angles, enhancing their versatility in different environments.

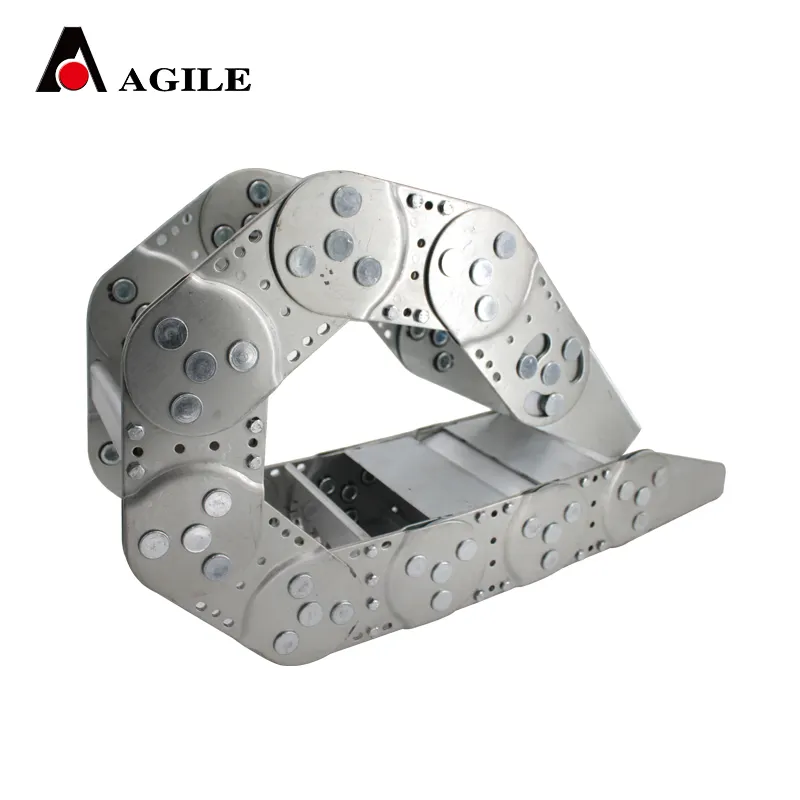

Another popular option in wood chip transportation is the chain conveyor. This type employs a series of linked chains to move materials along a track. Chain conveyors are particularly beneficial for heavy, bulky materials and offer an efficient means of moving wood chips from mills to storage areas or processing machines. Furthermore, they are resistant to wear and tear, making them suitable for environments with a high volume of processing.

wood chip conveyor

An emerging trend in wood chip conveyors is the incorporation of advanced technology. Many modern systems feature automated controls and sensors that monitor material flow, ensuring optimal performance. These innovations help reduce manual intervention, minimize operational costs, and significantly enhance overall efficiency. Real-time data collection can also help operators identify bottlenecks and optimize productivity.

Safety is another crucial aspect of wood chip conveyors. With the potential for accidents in industrial settings, manufacturers have implemented various safety features, such as emergency shut-off systems and protective covers. These measures help safeguard employees and reduce the risk of workplace injuries.

In addition to operational benefits, using a wood chip conveyor can have environmental advantages. By streamlining the transportation process, these systems help minimize material waste, ensuring that wood residues are efficiently utilized. This aligns with sustainability goals prevalent in the industry, as manufacturers seek to reduce waste and improve recycling practices.

In conclusion, wood chip conveyors play a pivotal role in enhancing the efficiency and productivity of wood processing facilities. With various designs available, ranging from belt to chain conveyors, these systems are tailored to meet diverse operational needs. As technology continues to evolve, we can expect further advancements that will enhance performance and safety, making wood chip conveyors an indispensable asset in the modern wood processing industry.