Non-split wire loom for effective cable management and protection solutions

Non-Split Wire Loom An Essential for Wire Management

In the realm of electrical installations and automotive wiring, effective cable management is crucial to ensuring safety, durability, and efficiency. One of the most efficient solutions for organizing and protecting wires is the non-split wire loom. This versatile product serves as a protective casing for electrical wires, safeguarding them from physical damage, abrasion, and environmental hazards. Understanding the features and benefits of non-split wire loom can greatly enhance your wiring projects.

What is Non-Split Wire Loom?

Non-split wire loom is a tubing designed to organize and protect multiple electrical wires. Unlike split wire loom, which has a slit along its length for easy insertion and removal of wires, non-split wire loom is a closed tube. This design provides enhanced protection as it completely encloses the wires, preventing exposure to outside elements. Typically made from high-density polyethylene (HDPE) or nylon, non-split wire loom is lightweight yet sturdy, making it ideal for both automotive applications and industrial settings.

Benefits of Using Non-Split Wire Loom

1. Protection Against Damage One of the primary advantages of non-split wire loom is its ability to protect wires from abrasion, heat, and chemical exposure. In environments where wires are prone to friction or contact with sharp edges, using a non-split wire loom can prevent insulation wear and extend the lifespan of the wiring.

2. Organized Wiring Non-split wire loom helps maintain a tidy and organized wiring setup. By grouping wires together, it minimizes clutter and makes troubleshooting or maintenance more straightforward. This organization is particularly valuable in automotive and industrial applications where space is limited, and ease of access is essential.

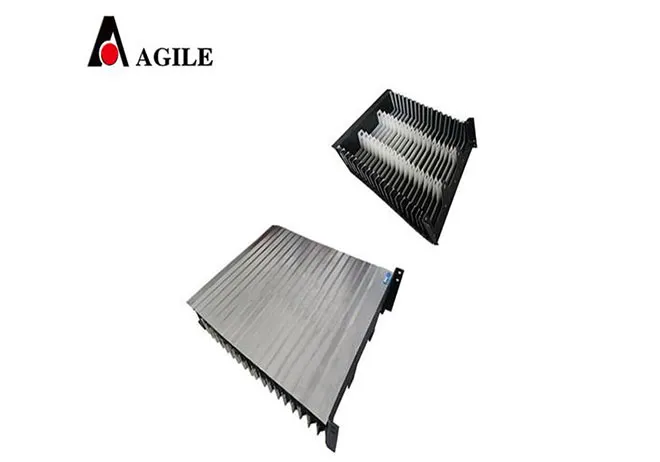

non split wire loom

3. Compatibility Non-split wire loom comes in various sizes to accommodate different wire gauges. This flexibility allows users to choose the perfect fit for their specific wiring needs, ensuring that cables are snugly secured within the loom.

4. UV and Chemical Resistance Many types of non-split wire loom are engineered to withstand exposure to UV light and various chemicals. This characteristic is especially important for outdoor applications or environments where wires may be exposed to potentially damaging substances.

5. Ease of Installation Installing non-split wire loom is relatively simple. The loom can be easily cut to the desired length and slid over the wires, providing a quick and efficient solution for cable management. This ease of use can save time and labor costs during installation.

Applications of Non-Split Wire Loom

Non-split wire loom is widely used in numerous applications, from automotive wiring harnesses to industrial machinery, home electrical systems, and even DIY projects. Its ability to protect and organize wires makes it an invaluable tool for electricians, mechanics, and anyone working with electrical systems.

Conclusion

In summary, non-split wire loom is an essential component for anyone involved in wiring projects that require organization and protection. Its robust design, ease of use, and protective qualities make it a favored choice for both professional and DIY users alike. By incorporating non-split wire loom into your wiring projects, you can enhance the safety and longevity of your electrical systems, ensuring a reliable performance for years to come.