hinge chip conveyor

Understanding Hinge Chip Conveyors An Essential Component in Material Handling

In the realm of industrial manufacturing, efficiency and reliability are paramount. Among various systems designed to transport materials, hinge chip conveyors have emerged as a fundamental solution, especially in the wood processing and metalworking industries. Known for their durability and versatility, these conveyors play a crucial role in the effective handling of chips, shavings, and other by-products of the manufacturing process.

What is a Hinge Chip Conveyor?

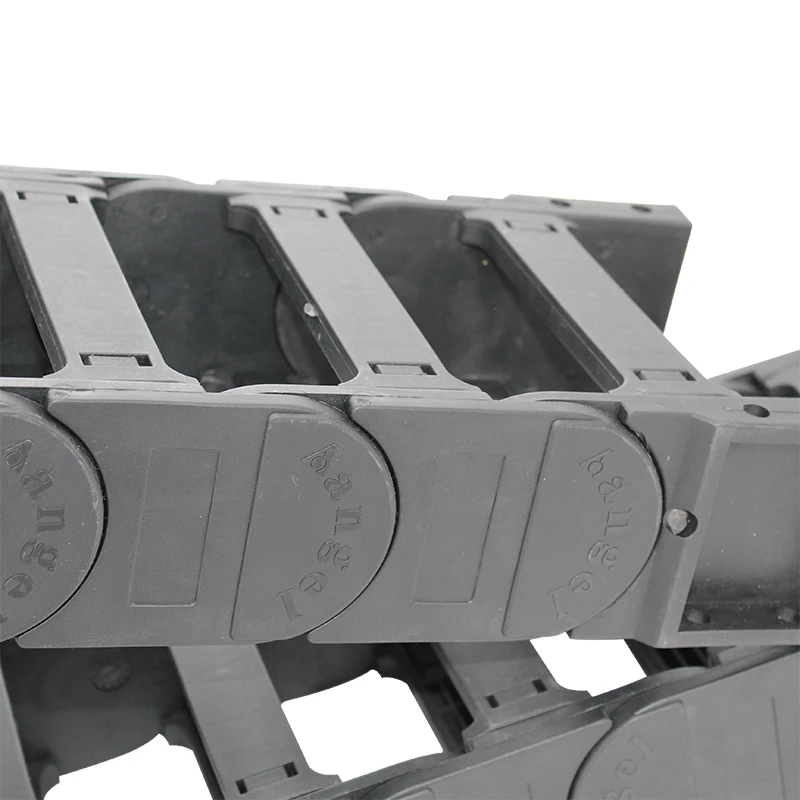

A hinge chip conveyor is a type of conveyor system that utilizes a series of interconnected metal plates or hinges to move materials from one place to another. Typically constructed from heavy-duty materials, these conveyors are designed to withstand the harsh conditions of industrial environments. The key feature of hinge chip conveyors is their ability to carry bulk materials, such as wood chips, metal shavings, and other similar debris, in a continuous motion.

How Do Hinge Chip Conveyors Work?

The operation of hinge chip conveyors is relatively simple yet effective. The conveyor consists of a series of metal plates that are linked together by hinges, forming a continuous belt-like structure. As the conveyor operates, a motor drives the system, allowing the hinged links to move in a controlled manner. This motion enables the conveyor to transport materials along a designated path, often utilizing inclines or declines to navigate different elevations in the facility.

Hinge chip conveyors are primarily designed to facilitate smooth transitions of materials from machinery to storage areas or waste processing units. They can be installed in various orientations and configurations, making them adaptable to diverse industrial layouts. Whether transporting wood chips from a sawmill or metal shavings from a machining center, these conveyors enhance the efficiency of the material handling process.

Advantages of Hinge Chip Conveyors

hinge chip conveyor

1. Durability One of the standout features of hinge chip conveyors is their robust construction. Designed to endure heavy loads and abrasive materials, these systems can operate effectively in tough environments. Their resilience ensures a longer lifespan, reducing maintenance needs and downtime.

2. Versatility Hinge chip conveyors are versatile and can be customized to meet specific industrial requirements. They can transport a wide range of materials, making them suitable for different processing industries, including forestry, metalworking, and recycling.

3. Efficient Material Handling By automating the transportation of chips and shavings, these conveyors significantly enhance productivity. They minimize the need for manual handling, reducing labor costs and the risk of workplace injuries.

4. Space Saving Hinge chip conveyors are designed to operate in confined spaces, making them an ideal choice for facilities with limited floor space. Their compact design allows them to fit into existing layouts without requiring extensive renovations.

5. Easy Maintenance With relatively few moving parts, hinge chip conveyors are easy to maintain. Regular inspections and minor adjustments can keep the system running smoothly, ensuring constant operational effectiveness.

Conclusion

Hinge chip conveyors are an integral part of modern industrial operations, providing efficient, reliable, and versatile material handling solutions. Their robust design, coupled with the ability to transport various types of debris, make them indispensable in sectors like woodworking and metal fabrication. As industries continue to evolve and demands for efficiency increase, hinge chip conveyors will undoubtedly remain a key component in optimizing material handling processes, contributing to the overall productivity of manufacturing systems.