Innovative Solutions for Flexible Cable Management Systems in Modern Industries

Understanding Flexible Cable Chains A Comprehensive Overview

In today's fast-paced industrial world, efficiency and organization are paramount. This is particularly true in environments that require the movement of machinery and equipment. One key component that aids in this endeavor is the flexible cable chain, an essential tool for managing and protecting cables and hoses in various applications, from manufacturing to robotics. In this article, we will explore what flexible cable chains are, their applications, benefits, and considerations for use.

What are Flexible Cable Chains?

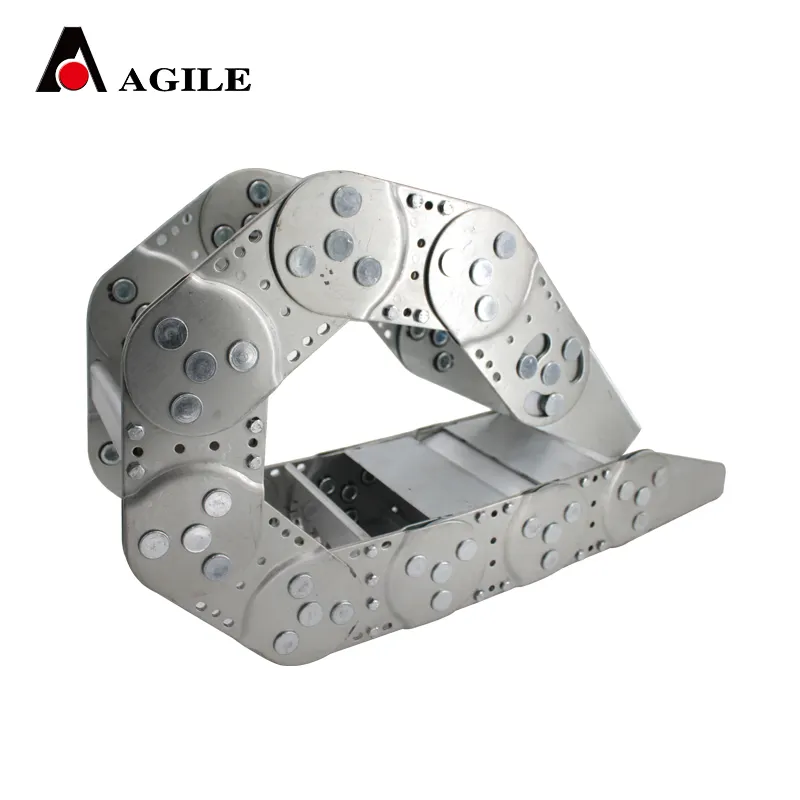

Flexible cable chains, often referred to as energy chains or drag chains, consist of interconnected links that form a channel for routing cables, hoses, and other flexible connections. Designed to protect these components from wear and damage while allowing for dynamic motion, these chains are engineered to accommodate the constant movement of machinery such as robotic arms, automated guided vehicles, and 3D printers. The primary function of a flexible cable chain is to provide a safe and organized path for cables and hoses, ensuring they do not tangle or become damaged during operation.

Applications of Flexible Cable Chains

Flexible cable chains find their applications across multiple industries. Some prominent examples include

1. Manufacturing In assembly lines, flexible cable chains ensure that robotic arms and conveyor systems operate smoothly by managing the necessary electrical and fluid connections.

2. Automotive In automotive production, these chains are vital in managing wiring harnesses and fluid lines, especially in assemblies where parts are constantly moving or being adjusted.

3. Aerospace In the aerospace industry, flexible cable chains are often employed in testing rigs and manufacturing equipment to ensure reliable performance under dynamic conditions.

4. Medical Equipment Hospitals and laboratories utilize flexible cable chains to manage cables in medical devices and equipment, minimizing clutter and preventing damage.

5. 3D Printing 3D printers require precise movements and controlled cable routing; therefore, flexible cable chains play a crucial role in their operation.

Benefits of Using Flexible Cable Chains

The adoption of flexible cable chains brings numerous advantages to various fields

1. Protection By covering cables and hoses, these chains protect them from mechanical damage, environmental factors, and accidental disconnections.

flexible cable chain

2. Organization Flexible cable chains help keep cables and hoses neatly organized, reducing clutter and making maintenance or troubleshooting much easier.

3. Flexibility Designed for dynamic applications, these chains can bend and twist as required, accommodating the movements of machinery without compromising the integrity of the cables within.

4. Reduced Wear and Tear The use of flexible cable chains minimizes the friction and wear that cables experience in dynamic applications, extending their lifespan.

5. Easy Installation Many flexible cable chain systems come ready for installation, often featuring modular designs that make customization straightforward and quick.

Considerations for Use

When selecting a flexible cable chain for a specific application, several factors should be taken into account

1. Load Capacity Assess the weight and type of cables or hoses that the chain will support to ensure it can handle the required load without deformation.

2. Bending Radius Determine the necessary bending radius for the application to ensure that the chain operates smoothly without stressing the cables inside.

3. Material Flexible cable chains are made from various materials such as plastic or metal. The choice of material should correspond to the operating environment, considering factors such as temperature, chemical exposure, and weight.

4. Length and Design Customization may be required regarding length and design based on the specific routing needs of the application.

5. Compatibility Ensure that the chosen cable chain is compatible with the connectors and components used in your machinery or system.

Conclusion

Flexible cable chains are an indispensable component of modern machinery. By providing efficient cable management and protection, they enhance operational efficiency and contribute to maintaining the integrity of critical connections in various industrial applications. As technology continues to evolve, the importance of such systems is likely to grow, highlighting the necessity for professionals to understand the intricacies of flexible cable chains and their optimal utilization. Whether in manufacturing, automotive, or any high-tech environment, investing in the right flexible cable chain can lead to significant enhancements in productivity and safety.