CNC Flexible Bellows Protection Solutions for Precision Machinery and Equipment

Understanding CNC Bellow Covers A Key Component in Precision Engineering

In the realm of precision engineering, the significance of protecting machinery and ensuring the longevity of mechanical components cannot be overstated. One of the critical components designed for this purpose is the CNC bellow cover. These covers serve a pivotal role in safeguarding the intricate parts of CNC (Computer Numerical Control) machines, which are indispensable in modern manufacturing processes. This article delves into the importance, design, and applications of CNC bellow covers, providing an insightful overview for professionals and enthusiasts alike.

What is a CNC Bellow Cover?

CNC bellow covers are protective coverings made from flexible materials, designed to shield the moving parts of CNC machines. Typically used in conjunction with linear actuators and ball screws, these bellow covers prevent the ingress of debris, coolant, and other contaminants that could adversely affect machine performance. They are engineered to fit snugly around vulnerable components, ensuring maximum protection without hindering the machine’s operation.

The Importance of Bellow Covers

The primary function of CNC bellow covers is to protect sensitive parts from wear and tear caused by environmental factors. In a manufacturing setting, machines are often exposed to dust, chips, coolant, and other particulate matter that can lead to considerable damage over time. Without proper protection, such contaminants can cause malfunction, degrade performance, and necessitate expensive repairs or replacements.

Moreover, ensuring the cleanliness of machine components is crucial for maintaining precision. CNC machines operate on tight tolerances, and any foreign substance could compromise the accuracy of the final product. By employing bellow covers, manufacturers can significantly reduce downtime and maintain the integrity of their machining processes.

Design Features

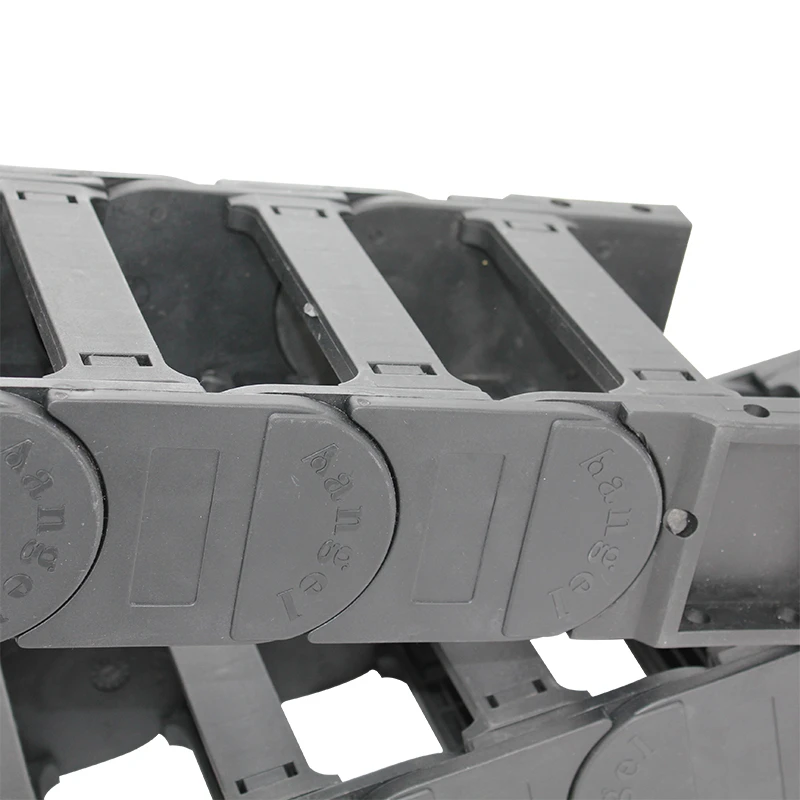

cnc bellow cover

CNC bellow covers come in various styles and materials, tailored to meet specific application requirements. They are typically made from materials such as rubber, polyurethane, or nylon, offering durability while remaining flexible. The design often incorporates pleats or folds that allow the cover to expand and contract as the machine moves, preventing snagging while providing a tight seal.

Additionally, custom bellow covers can be engineered to accommodate specific dimensions and machine configurations. This customization ensures that the covers provide optimal protection without impeding the machine’s functionality. Furthermore, the aesthetic appeal of these covers can enhance the overall appearance of the machinery, contributing to a professional look in the manufacturing environment.

Applications of CNC Bellow Covers

CNC bellow covers are widely utilized across various industries where precision machining is paramount. Common applications include

1. Metalworking In milling, turning, and grinding operations, bellow covers protect essential components from metal shavings and cutting fluids. 2. Woodworking CNC machines used for cutting and shaping wood also require protection from sawdust and wood chips, making bellow covers a critical accessory. 3. Automotive and Aerospace In these sectors, where precise components are crucial for safety and performance, bellow covers facilitate the longevity of CNC machinery.

4. Medical Device Manufacturing As the demand for precision in medical equipment increases, the role of bellow covers in preventing contamination from external factors becomes vital.

Conclusion

In conclusion, CNC bellow covers play a fundamental role in the preservation and performance of CNC machines. By safeguarding sensitive components from contaminants and wear, these protective covers not only enhance the lifespan of the machinery but also contribute to the precision and accuracy required in various manufacturing processes. As industries continue to evolve and prioritize efficiency and quality, the importance of CNC bellow covers will undoubtedly endure. Investing in high-quality bellow covers is essential for any organization that relies on CNC technology, ensuring optimal performance and reliability in today's competitive environment.