cable chain cnc

Understanding Cable Chains in CNC Applications

In the realm of CNC (Computer Numerical Control) machining, effective management of cable systems is critical for ensuring the seamless operation of machines. One of the pivotal components in this design is the cable chain, which serves both functional and structural purposes. This article delves into the importance of cable chains in CNC applications, their types, benefits, and considerations for choosing the right one.

What is a Cable Chain?

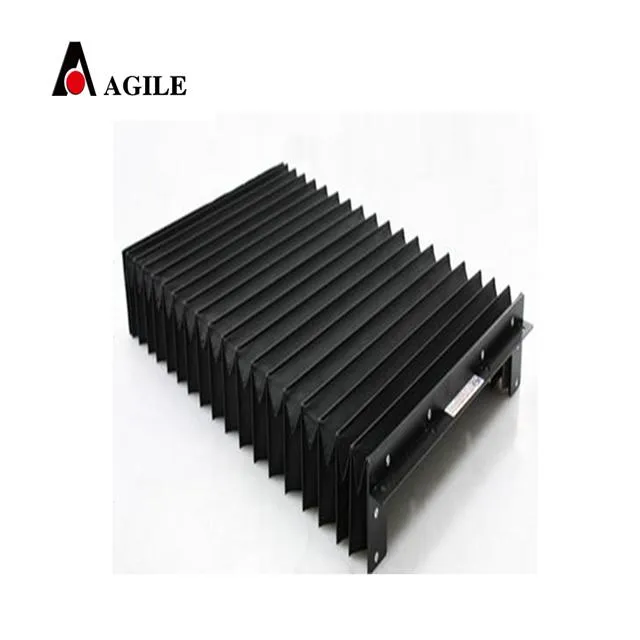

A cable chain, also known as a drag chain or energy chain, is a modular system designed to guide and protect cables, hoses, and other moving items in automated machinery. These chains are constructed using a series of interconnected links that form a flexible yet robust support structure, allowing cables to move freely while keeping them organized and preventing wear and tear.

The Role of Cable Chains in CNC Machinery

In CNC machines, where precision and efficiency are paramount, cable chains facilitate the movement of power, control, and signal lines. As CNC machines move in different axes (X, Y, Z), the cables that supply power to motors and sensors can become entangled or damaged without proper management. Cable chains help mitigate these issues by providing a designated pathway that keeps cables safe from sharp edges, fraying, and environmental hazards.

Types of Cable Chains

There are several types of cable chains available, each designed to meet specific needs

cable chain cnc

1. Plastic Cable Chains Lightweight and resistant to chemicals and UV light, plastic cable chains are often used in environments where weight considerations are crucial. 2. Metal Cable Chains Typically made from steel or aluminum, these chains offer greater durability and strength. They are ideal for heavy-duty applications but come with increased weight. 3. Closed Cable Chains These chains feature a continuous design that provides complete enclosure for the cables. They are particularly beneficial in high-dust or hazardous environments. 4. Open Cable Chains With a more accessible design, open cable chains allow for easy insertion and removal of cables but offer less protection compared to closed chains.

Benefits of Using Cable Chains

1. Protection Cable chains shield cables from abrasion, cuts, and impacts, extending their lifespan significantly. 2. Organization They help keep cables neatly organized, reducing the risk of tangling and facilitating maintenance. 3. Increased Flexibility Cable chains allow for unrestricted movement, enabling CNC machines to operate at their full potential without the fear of cable entanglement. 4. Improved Safety With reduced cable exposure, the risk of trips and electrical hazards in the work environment is minimized.

Selecting the Right Cable Chain

Choosing the appropriate cable chain for a CNC application requires careful consideration of several factors

1. Cable Type and Size Assess the dimensions and types of cables that will be used. Ensure the cable chain can accommodate the necessary weight and flexibility. 2. Operating Environment Evaluate the working conditions, such as temperature, exposure to chemicals, and potential debris. Select a material that best suits these conditions. 3. Travel Distance Consider the range of motion required for the CNC machine. The length and design of the cable chain should align with the travel distance to prevent overstretching or excessive slack. 4. Installation Space Measure the installation area to ensure that the selected cable chain will fit within the existing framework of the CNC machine.

Conclusion

Cable chains are an essential component in the design and operation of CNC machines, providing protection, organization, and flexibility for cable management. By understanding the different types of cable chains available and their specific benefits, manufacturers can select the right solution that enhances the performance and safety of their machinery. In a field where precision and reliability are crucial, investing in quality cable chains is a decision that pays dividends in efficiency and long-term operational success.