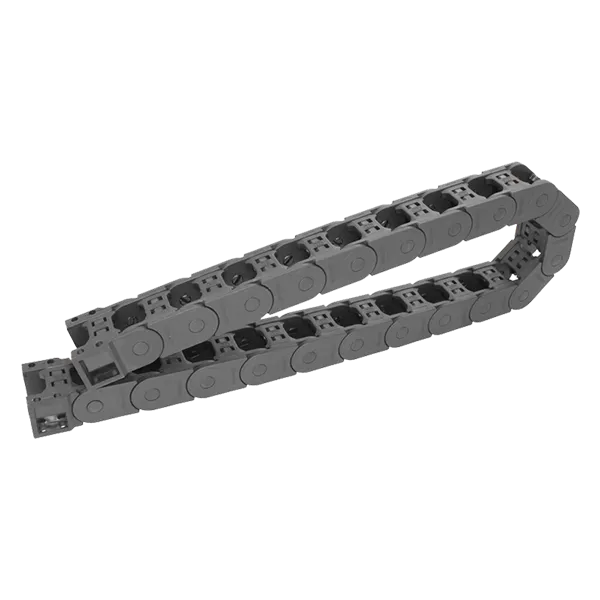

Durable and Flexible Plastic Cable Carrier Chain for Efficient Cable Management Systems

The Versatility of Plastic Flexible Cable Carrier Chains

In the rapidly evolving world of technology and automation, the need for efficient cable management systems is paramount. One such solution that has emerged to address this necessity is the plastic flexible cable carrier chain. These innovative structures have found widespread applications across various industries due to their ability to manage and protect cables and hoses effectively.

What is a Plastic Flexible Cable Carrier Chain?

A plastic flexible cable carrier chain, also known as an energy chain or drag chain, is a modular system designed to safeguard and organize multiple cables, hoses, and other essential components in automated machinery. Made from high-quality plastic materials, these chains are lightweight yet robust, making them ideal for dynamic environments where movement and flexibility are required.

The design of a plastic cable carrier chain consists of interlocking links that can be easily assembled in various configurations, allowing for customization based on specific application needs. They are particularly prized for their ability to guide cables in a controlled manner, preventing wear and tear caused by friction and movement.

Benefits of Using Plastic Flexible Cable Carrier Chains

1. Durability and Weight Saving Plastic cable carrier chains are significantly lighter than their metal counterparts, which contributes to reduced energy consumption in machinery. Additionally, the materials used are often resistant to chemicals, UV rays, and moisture, ensuring a prolonged lifespan.

2. Flexibility These cable carriers can accommodate a wide variety of cables and hoses, facilitating the management of power, data, and pneumatic lines within a single chain. Their flexibility enables them to navigate bends and curves, which is essential in complex machinery setups.

plastic flexible cable carrier chain

3. Customization Plastic flexible cable carrier chains come in various sizes, shapes, and configurations, allowing manufacturers and engineers to tailor the system to their unique requirements. This customization capability enhances the efficiency of cable routing in machines.

4. Ease of Installation and Maintenance Constructed with a user-friendly design, these chains are straightforward to install and maintain. Many designs offer easy access to internal components, making it simpler to replace or reposition cables as needed.

5. Noise Reduction The use of plastic in these chains can significantly reduce noise generated during operation, contributing to a quieter working environment in factories and workshops.

Applications of Plastic Flexible Cable Carrier Chains

The versatility of plastic flexible cable carrier chains has led to their adoption in numerous industries, including

- Manufacturing These chains are extensively used in CNC machines, robotics, and automated production lines for effective cable management. - Material Handling In warehousing and logistics, cable carrier chains are implemented in conveyor systems to maintain organization and prevent damage to wires. - Automotive The automotive industry uses these chains in assembly lines and robotic applications, ensuring smooth operation and safety. - Medical Equipment In medical devices, cable carriers protect sensitive cables and hoses, facilitating precise movements without risk of damage.

Conclusion

Plastic flexible cable carrier chains represent a significant advancement in the domain of cable management systems. Their unique combination of durability, flexibility, and customization underscores their increasing importance in modern automated environments. As industries continue to embrace automation and advanced technologies, the role of these carrier chains will only become more critical. By effectively managing cables and hoses, they not only enhance the operational efficiency of machines but also contribute to the overall safety and effectiveness of industrial processes. The future of manufacturing and automation is undoubtedly intertwined with innovations like the plastic flexible cable carrier chain, paving the way for a more organized and optimized working environment.