Machine Bellows Covers: The Essential Protective Solution

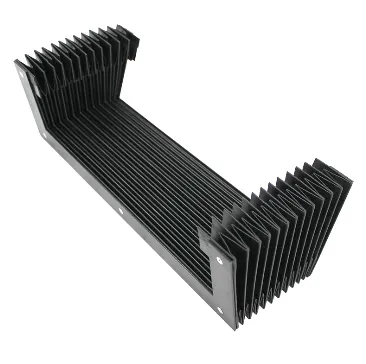

In any industrial setting, the protection of sensitive machinery and components is essential to ensure optimal performance and longevity. One of the most effective solutions to safeguard machinery is the use of machine bellows covers. These protective covers are designed to shield equipment from dirt, dust, moisture, and other external contaminants, significantly reducing wear and tear and ensuring smooth operations.

Machine bellows covers are flexible and durable, made from materials that can withstand harsh environments. They are particularly useful for protecting moving parts, such as guide rails, slides, and spindles, from damage caused by friction or exposure to debris. These covers offer significant protection by preventing foreign particles from infiltrating delicate machinery, which can lead to costly repairs and downtime.

Manufacturers across various industries, including automation, machining, and manufacturing, rely on machine bellows covers to extend the lifespan of their equipment. The covers come in various shapes and sizes to accommodate different machine types, ensuring that machinery remains safe from environmental factors that may disrupt their functionality.

The benefits of machine bellows covers go beyond protection. They also improve the operational efficiency of machinery by reducing the need for maintenance and keeping components clean. By investing in these covers, companies can improve both the performance and durability of their equipment, resulting in reduced operational costs over time.

Bellow Cover Manufacturer: Leading the Way in Quality and Customization

When it comes to finding the perfect protective solution for machinery, choosing the right bellow cover manufacturer is key. A reliable and experienced manufacturer understands the intricacies of designing and producing high-quality bellow covers that meet the needs of diverse industries. The best manufacturers offer customization options to ensure that each bellow cover is tailored to the specific requirements of the machinery it’s designed to protect.

A bellow cover manufacturer typically offers a variety of materials, including rubber, fabric, and metal, to provide versatile solutions for various industrial applications. The choice of material depends on the specific needs of the machinery and the environment in which it operates. For example, rubber bellows are commonly used for their flexibility and ability to withstand harsh conditions, while metal bellows are preferred for high-temperature environments where durability and strength are essential.

Another important consideration when selecting a bellow cover manufacturer is the quality of their manufacturing process. Top manufacturers use advanced technology and quality control processes to ensure that each cover is produced to the highest standards. This attention to detail ensures that the bellow covers are long-lasting, reliable, and perform well even in demanding environments.

By working with a skilled bellow cover manufacturer, companies can ensure that their equipment remains well-protected from dust, debris, and other contaminants, reducing the risk of malfunctions and downtime.

Rubber Bellows Dust Cover: Superior Protection for Sensitive Components

For machinery exposed to heavy wear and tear, as well as environments where fine dust and debris are prevalent, a rubber bellows dust cover offers the best protective solution. Rubber bellows are known for their durability, flexibility, and ability to withstand a wide range of temperatures, making them ideal for use in demanding industrial settings.

The rubber bellows dust cover is designed to protect sensitive components like spindles, guide rails, and moving parts from the damaging effects of dust and debris. The flexible rubber material allows the cover to expand and contract with the movement of the machinery, ensuring that the components remain covered at all times. This flexibility is particularly important in environments where machinery is subject to constant movement or vibration.

One of the key benefits of rubber bellows dust covers is their ability to provide a tight seal around moving parts, preventing particles from entering and causing damage. This helps reduce the likelihood of equipment failure due to contamination, which can result in costly repairs or downtime. Additionally, rubber bellows covers are highly resistant to wear, tear, and aging, ensuring long-lasting protection and minimal maintenance.

Manufacturers and machine operators often choose rubber bellows dust covers for their ability to handle tough conditions. These covers are versatile and can be customized to fit a wide range of machinery, providing both functional and aesthetic benefits. Whether in the automotive, manufacturing, or automation industry, a rubber bellows dust cover is an essential investment for protecting valuable equipment.

Guide Rail Bellow Cover: Maintaining Cleanliness and Performance

In many industrial machines, guide rails are critical components that require continuous protection from dust, debris, and other harmful elements. The guide rail bellow cover is specifically designed to shield guide rails and other sensitive parts from contamination while maintaining their cleanliness and performance. These covers are essential for maintaining the precision and functionality of machinery, particularly in environments where the buildup of dust can affect the accuracy of the equipment.

The guide rail bellow cover is typically made from durable materials such as rubber, plastic, or fabric, and is engineered to withstand harsh working conditions. The cover's flexible design allows it to fit snugly around guide rails, protecting them from dirt, moisture, and other contaminants that can cause wear and reduce the lifespan of the equipment.

One of the main advantages of using a guide rail bellow cover is its ability to improve the overall efficiency of machinery. By preventing dust and debris from entering the guide rails, the cover ensures that the machinery operates smoothly and with greater precision. This can result in higher-quality output, less downtime, and fewer repairs or maintenance requirements.

Guide rail bellow covers are available in various sizes and designs, allowing manufacturers to select the best fit for their machinery. Customization options are also available, ensuring that the covers are tailored to the specific needs of the equipment. As industries increasingly focus on maximizing efficiency and minimizing downtime, the use of guide rail bellow covers has become a critical component of machinery maintenance.

FAQs

What are the benefits of using machine bellows covers for industrial equipment?

A3: Machine bellows covers provide significant protection for industrial equipment by preventing the buildup of dirt, dust, and other contaminants. This protection helps to extend the life of machinery and reduces the likelihood of malfunctions or costly repairs. Additionally, machine bellows covers can reduce maintenance needs, lower downtime, and enhance operational efficiency by ensuring that moving parts remain clean and protected from external elements.

How can I choose the right bellow cover manufacturer for my needs?

A3: When selecting a bellow cover manufacturer, it’s important to consider factors such as material options, customization capabilities, and the manufacturer’s experience. Look for manufacturers who specialize in high-quality, durable covers and offer a variety of materials such as rubber, fabric, and metal. Additionally, ensure that the manufacturer can provide tailored solutions to meet the specific requirements of your machinery.

What materials are commonly used for rubber bellows dust covers?

A3: Rubber bellows dust covers are typically made from high-quality rubber materials such as neoprene, silicone, or nitrile. These materials are chosen for their flexibility, durability, and resistance to wear, aging, and environmental factors like heat and moisture. Rubber bellows are particularly effective at preventing dust and debris from entering sensitive machinery components.

Why are guide rail bellow covers important for machinery maintenance?

A3: Guide rail bellow covers are crucial for maintaining the cleanliness and precision of guide rails in industrial machinery. They prevent dust, dirt, and other contaminants from damaging the guide rails, which can affect the accuracy and performance of the machinery. By using guide rail bellow covers, companies can extend the lifespan of their equipment, reduce maintenance costs, and ensure smoother, more efficient operations.

Can machine bellows covers be customized to fit specific machinery?

A3: Yes, machine bellows covers can be customized to fit the exact specifications of your machinery. Manufacturers offer a variety of materials, sizes, and designs to ensure that the covers provide the best protection for your equipment. Customization options may include adjusting the cover’s length, shape, or material to suit particular needs, such as increased flexibility or enhanced durability.