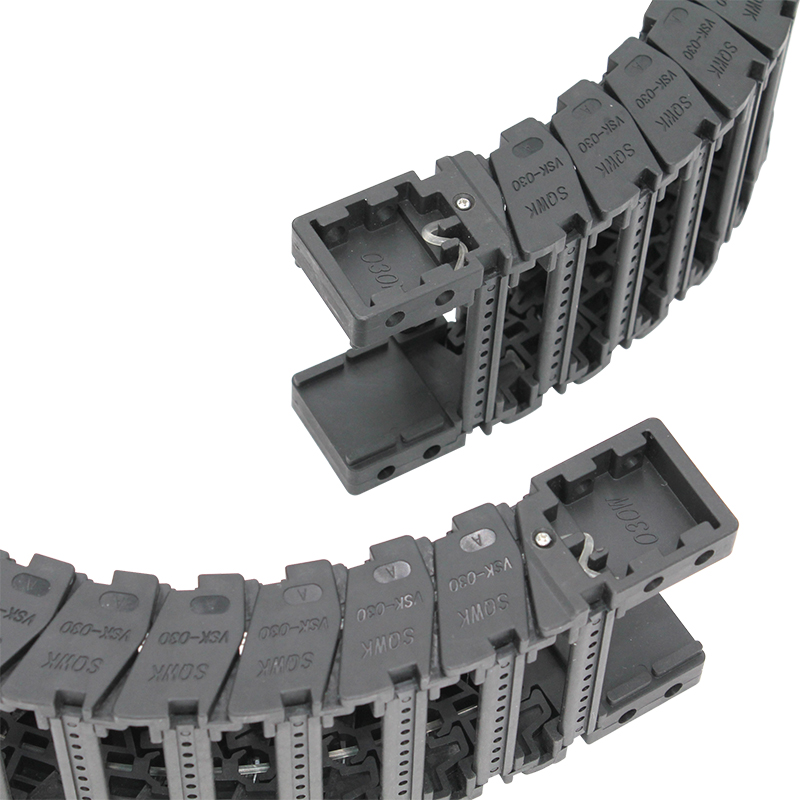

wire drag chain

Understanding Wire Drag Chains An Essential Component in Modern Engineering

In the world of manufacturing and automation, wire drag chains, also known as cable carriers or cable track systems, play a crucial role in ensuring the smooth operation of machinery and equipment. Designed to manage and protect cables, hoses, and other flexible elements, wire drag chains offer a multitude of benefits across various industries, including robotics, automotive, and telecommunications. This article delves into the significance of wire drag chains, their components, and their applications.

What are Wire Drag Chains?

Wire drag chains are protective conduits that guide and support flexible media—such as electrical cables, pneumatic hoses, and hydraulic lines—while allowing for unrestricted movement of machinery. These chains are constructed from a variety of materials, including plastic, steel, and aluminum, allowing for customization based on the application’s demands. The primary function of wire drag chains is to prevent tangling, abrasion, and wear, which can lead to equipment failure and costly downtime.

Components of Wire Drag Chains

The design of wire drag chains typically includes several essential components

1. Chain Links These are the fundamental building blocks of the drag chain. They are designed to bend and flex, allowing the chain to adapt to the movement of equipment. The links can be opened for easy access to the cables and hoses inside.

2. Mounting Brackets These components secure the drag chain to the machinery or structure, providing stability and ensuring proper alignment during operation.

3. Dividers Some wire drag chains come equipped with dividers that separate different cables or hoses within the chain. This organization prevents interference and reduces wear between components.

4. End Connectors These are used to link the chain to other equipment or structures. Properly designed connectors ensure seamless integration and facilitate the movement of cables and hoses without strain.

Benefits of Using Wire Drag Chains

1. Protection By enclosing cables and hoses, wire drag chains shield them from dirt, debris, and abrasion. This protection significantly extends the lifespan of these components and reduces maintenance costs.

wire drag chain

2. Mobility Wire drag chains enhance the mobility of robotics and automated machinery. They allow for smooth movement in all directions while keeping the cables secure and organized.

3. Versatility Available in a range of sizes, shapes, and materials, wire drag chains can be tailored to meet the specific needs of various applications, from small robotics systems to large industrial machinery.

4. Ease of Installation and Maintenance Most wire drag chains are designed for straightforward installation and can be easily opened for maintenance. This reduces downtime in production settings and allows for quick adjustments as needed.

Applications of Wire Drag Chains

Wire drag chains are utilized in numerous sectors, including

- Manufacturing In automated production lines, drag chains help manage the numerous cables and hoses connected to machinery, ensuring that they move freely without risk of entanglement.

- Robotics In robotic applications, wire drag chains keep electrical and pneumatic lines organized, allowing robots to perform tasks efficiently without hindrance.

- Telecommunications In telecom infrastructure, drag chains protect the sensitive cables necessary for communication equipment, ensuring reliability and effectiveness.

- Automotive In automotive manufacturing, wire drag chains manage the multitude of cables in assembly lines, enhancing both productivity and safety.

Conclusion

Wire drag chains are an indispensable component in modern engineering, offering protection, flexibility, and organization for various cables and hoses used in machinery. Their versatility and efficiency make them a wise investment for industries looking to improve operational effectiveness and reduce maintenance downtime. As technology continues to advance, the role of wire drag chains will only become more prominent, further solidifying their place in the future of manufacturing and automation.