Creating an Optimal Wire Cable Track System for Efficient Organization and Accessibility

Understanding Wire Cable Tracks Applications, Benefits, and Installation

Wire cable tracks have become integral to modern industrial operations, especially in environments that require streamlined cable management and efficient movement of machinery. These tracks are designed to hold and guide cables and wires, ensuring that they do not become tangled or damaged during operation. In numerous sectors—from manufacturing to robotics and construction—wire cable tracks play a crucial role in maintaining an organized workplace, enhancing safety, and improving equipment longevity.

What Are Wire Cable Tracks?

Wire cable tracks, often referred to as cable carriers or drag chains, are systems that support and manage the cables and hoses that power and control machinery. They are typically made from materials such as plastic or metal and are designed to protect cables from wear and tear caused by movement, vibration, and environmental factors. Their design allows for smooth movement in a variety of applications, including linear and rotary movements.

Applications of Wire Cable Tracks

Wire cable tracks are utilized in a vast array of applications across different industries. They can be found in automated manufacturing systems, CNC machines, robotics, and conveyor systems. In the construction industry, for example, they are vital in cranes and booms where multiple cables need to move safely and efficiently. Likewise, in the automotive sector, wire cable tracks are common in assembly lines that require reliable power and data transfer to robotics.

Additionally, wire cable tracks are employed in heavy equipment, such as excavators and bulldozers, where they guide hydraulic hoses and electrical wiring

. They are also used in entertainment industries for stage equipment and lighting, ensuring cables are organized and safe from accidental disconnection or damage.Benefits of Wire Cable Tracks

1. Organization One of the most significant advantages of using wire cable tracks is the enhanced organization they provide. By keeping cables neatly arranged, they reduce clutter in workspaces, making it easier for operators to navigate and interact with machinery.

2. Protection Wire cable tracks offer excellent protection against abrasion, crush damage, and environmental impacts. This prolongs the life of cables, reducing maintenance costs and preventing unexpected downtime due to cable failure.

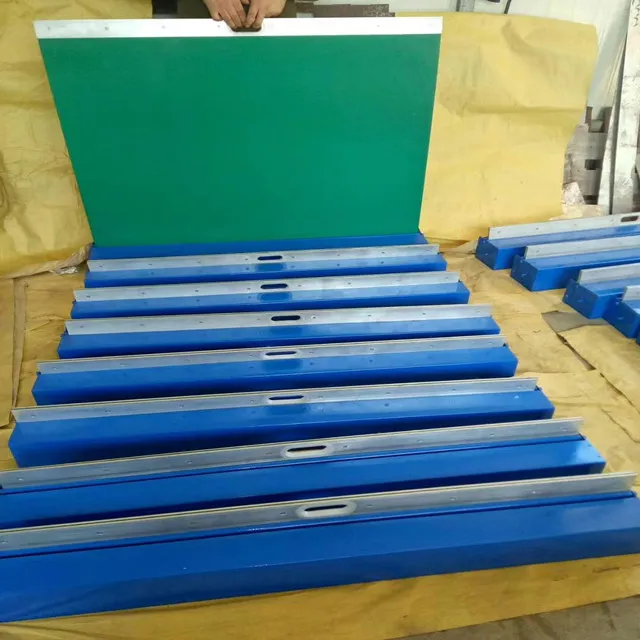

wire cable track

3. Flexibility These tracks are designed to accommodate a wide range of cable sizes and types, making them versatile solutions suitable for a plethora of applications. They can be configured to fit specific environments and operational needs, providing tailored solutions for businesses.

4. Safety By preventing cable tangling and damage, wire cable tracks help enhance workplace safety. They minimize the risk of trips and falls caused by loose wires, creating a safer environment for all personnel.

5. Ease of Installation Many wire cable tracks are designed for easy installation and maintenance. Their modular nature allows for quick assembly and adjustments, reducing downtime during setup.

Installation Considerations

When installing wire cable tracks, several key factors should be considered to ensure optimal performance

1. Cable Type and Load Assess the types and quantities of cables that will be housed within the track. Ensure that the chosen track can accommodate the cables’ sizes, weights, and functions.

2. Movement Requirements Determine the range of motion required for the application. Different setups may require varying track lengths and configurations, depending on the machinery involved.

3. Mounting Solutions Evaluate the best mounting options available for your setup. Wire cable tracks can be mounted on various surfaces, and the mounting approach will impact the overall effectiveness and ease of use.

4. Environment Consider the environmental conditions the cable tracks will be exposed to. For instance, harsher environments may necessitate specialized materials to prevent rust or corrosion.

In conclusion, wire cable tracks are indispensable in many industrial applications due to their ability to organize, protect, and streamline cable management. By understanding the advantages and installation processes associated with these systems, businesses can enhance operational efficiency, ensure safety, and prolong the lifespan of their equipment. Whether in manufacturing, construction, or any other industry utilizing machinery, investing in reliable wire cable tracks can lead to significant operational improvements and cost savings.