Understanding the Basics and Applications of Synchronous Belts in Mechanical Systems

What is a Synchronous Belt?

A synchronous belt, often referred to as a timing belt, is a crucial component in various mechanical systems, particularly in engines and conveyor systems. This type of belt is characterized by its unique construction, which includes evenly spaced teeth that engage with corresponding notches on pulleys. This design enables synchronous belts to maintain a precise alignment and timing between rotating components, which is essential for numerous applications.

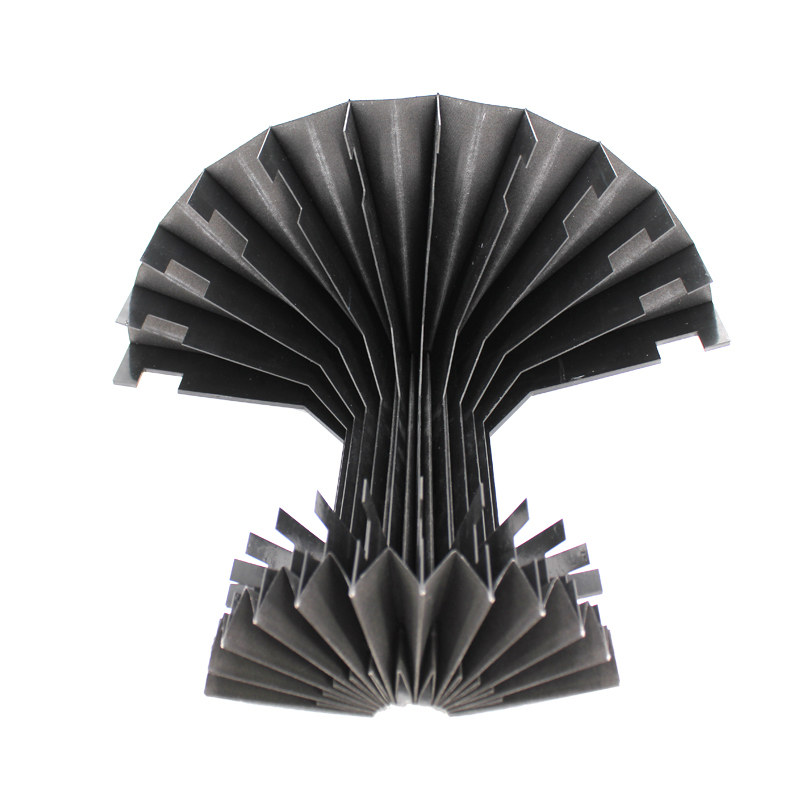

Construction and Materials

Synchronous belts are typically made from durable materials such as rubber, polyurethane, or neoprene, often reinforced with fibers like fiberglass or steel. The reinforcement ensures that the belt can withstand significant mechanical stresses while maintaining flexibility and durability. The toothed profile of the belt allows it to mesh effectively with the pulleys, providing a positive engagement that prevents slippage—a common failure mode in standard v-belts.

Working Principle

The operation of a synchronous belt is based on the principle of positive drive. When the motor or another driving component turns the pulley, the teeth of the synchronous belt engage with those on the driven pulley. Since the teeth are designed to fit snugly into the notches, this ensures that for every rotation of the driving pulley, a precise amount of movement is transferred to the driven pulley. This one-to-one ratio is vital in applications where accurate timing is crucial, such as in automotive engines, where the synchronisation of the crankshaft and camshaft is necessary for optimal performance.

Applications

Synchronous belts are widely used in various industries. In automotive applications, they are essential in ensuring that the engine valves open and close at the correct times relative to the position of the pistons. Failing to maintain this timing can lead to inefficient engine performance or catastrophic engine failure. Synchronous belts are also prominent in manufacturing machinery, robotics, and conveyor systems where precise motion control is needed for tasks such as positioning, indexing, and material handling.

what is a synchronous belt

Another key application of synchronous belts is in home appliances, where they may be used to drive washing machine drums or other rotating components. In all these cases, the precision and reliability of synchronous belts make them an indispensable choice.

Advantages of Synchronous Belts

One of the primary advantages of synchronous belts is their ability to maintain precise timing and avoid slippage. This leads to improved efficiency and better performance compared to other belt types. Additionally, synchronous belts can operate quietly and with minimal vibration, contributing to a more stable and less noisy system.

Moreover, synchronous belts often have a longer lifespan than traditional belts since they do not experience the same level of friction and wear. This longevity can reduce maintenance costs and downtime in both industrial and automotive contexts, making them a cost-effective option in the long run.

Disadvantages

Despite their many advantages, synchronous belts are not without their drawbacks. One major concern is their specific alignment and tension requirements. Improperly aligned systems or insufficient tension can lead to premature wear or failure of the belt. Additionally, while synchronous belts are designed to withstand significant load, they can be more susceptible to damage from shock loads or impacts compared to v-belts.

Conclusion

In summary, a synchronous belt is an essential mechanical component that plays a crucial role in various applications requiring precision and reliability. Its unique construction, consisting of toothed profiles that engage with pulleys, allows for synchronized motion, making it an invaluable choice for automotive, industrial, and home applications alike. While they do have some disadvantages, the advantages of synchronous belts—such as their precise timing capabilities, reduced noise, and longevity—often outweigh these concerns, solidifying their place in modern mechanical systems.