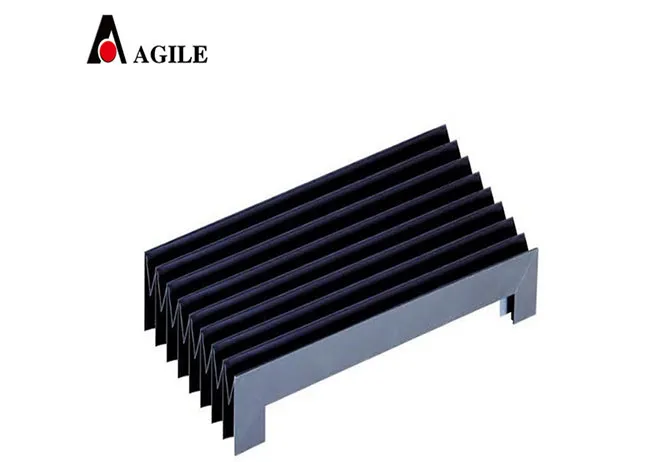

cnc machine used metal swarf chip conveyor

In the world of manufacturing and CNC machining, efficient waste management is critical for maintaining productivity and ensuring a clean working environment. One key tool in achieving this is the chip conveyor, an often-underestimated component that plays a pivotal role in maintaining workflow efficiency in modern industries. A chip conveyor is specifically designed to collect and transport metal chips, shavings, and other debris away from the cutting area to a designated disposal unit or recycling receptacle, ensuring that machine downtime is minimized and precision is maximized.

Integration of a chip conveyor into a manufacturing setup not only helps in maintaining cleanliness and preventing potential hazards, but it also plays a significant role in recycling efforts. Many facilities can incorporate chip conveyors into their recycling systems, segregating different materials and effectively reducing their environmental impact. This contributes to corporate sustainability goals and aligns with industry standards for waste reduction. Furthermore, the use of chip conveyors extends the life of machining tools by preventing excessive wear caused by chip accumulation on cutting surfaces and machinery. This indirectly leads to cost savings as it reduces the frequency of tool replacements and maintenance interventions. Progressive facilities recognize the value of investing in high-quality chip conveyors to enhance their operational capabilities and ensure consistent productivity. When selecting a chip conveyor, businesses must consider several factors beyond just cost. The type of material being machined, the volume of chips produced, the available workshop space, and the existing waste management infrastructure all influence the appropriate choice of conveyor system. Consulting with industry experts and conveyor manufacturers can provide valuable insights into the best systems customized to meet specific operational needs. Ultimately, the importance of a chip conveyor cannot be overstated. As manufacturing becomes increasingly sophisticated, maintaining an efficient, clean, and sustainable work environment is paramount. The performance, reliability, and integration of chip conveyors make them indispensable to modern manufacturing processes, underpinning not only productivity but also technological advancements within the industry. By understanding their function and capabilities, industry leaders can make informed decisions that drive their operations forward while aligning with environmental and economic goals.

Integration of a chip conveyor into a manufacturing setup not only helps in maintaining cleanliness and preventing potential hazards, but it also plays a significant role in recycling efforts. Many facilities can incorporate chip conveyors into their recycling systems, segregating different materials and effectively reducing their environmental impact. This contributes to corporate sustainability goals and aligns with industry standards for waste reduction. Furthermore, the use of chip conveyors extends the life of machining tools by preventing excessive wear caused by chip accumulation on cutting surfaces and machinery. This indirectly leads to cost savings as it reduces the frequency of tool replacements and maintenance interventions. Progressive facilities recognize the value of investing in high-quality chip conveyors to enhance their operational capabilities and ensure consistent productivity. When selecting a chip conveyor, businesses must consider several factors beyond just cost. The type of material being machined, the volume of chips produced, the available workshop space, and the existing waste management infrastructure all influence the appropriate choice of conveyor system. Consulting with industry experts and conveyor manufacturers can provide valuable insights into the best systems customized to meet specific operational needs. Ultimately, the importance of a chip conveyor cannot be overstated. As manufacturing becomes increasingly sophisticated, maintaining an efficient, clean, and sustainable work environment is paramount. The performance, reliability, and integration of chip conveyors make them indispensable to modern manufacturing processes, underpinning not only productivity but also technological advancements within the industry. By understanding their function and capabilities, industry leaders can make informed decisions that drive their operations forward while aligning with environmental and economic goals.