what is a chip conveyor

Understanding Chip Conveyors An Essential Component in Manufacturing

In the realm of manufacturing, efficient material handling is a crucial aspect that can significantly impact productivity. One of the key components in modern machining processes is the chip conveyor. Designed to transport metal chips and swarf generated during machining operations, chip conveyors play a vital role in maintaining a clean and efficient workspace. In this article, we will explore what a chip conveyor is, its types, and its importance in the manufacturing industry.

What is a Chip Conveyor?

A chip conveyor is a mechanical device used to remove metal chips and shavings generated during machining operations such as milling, turning, and drilling. These chips can accumulate rapidly, leading to machine tool malfunctions, increased labor for cleaning, and potential safety hazards. Chip conveyors are engineered to provide a systematic way of collecting and transporting these materials away from the machine tool, ensuring an uninterrupted workflow.

Types of Chip Conveyors

There are various types of chip conveyors, each designed to address the specific needs of different machining applications.

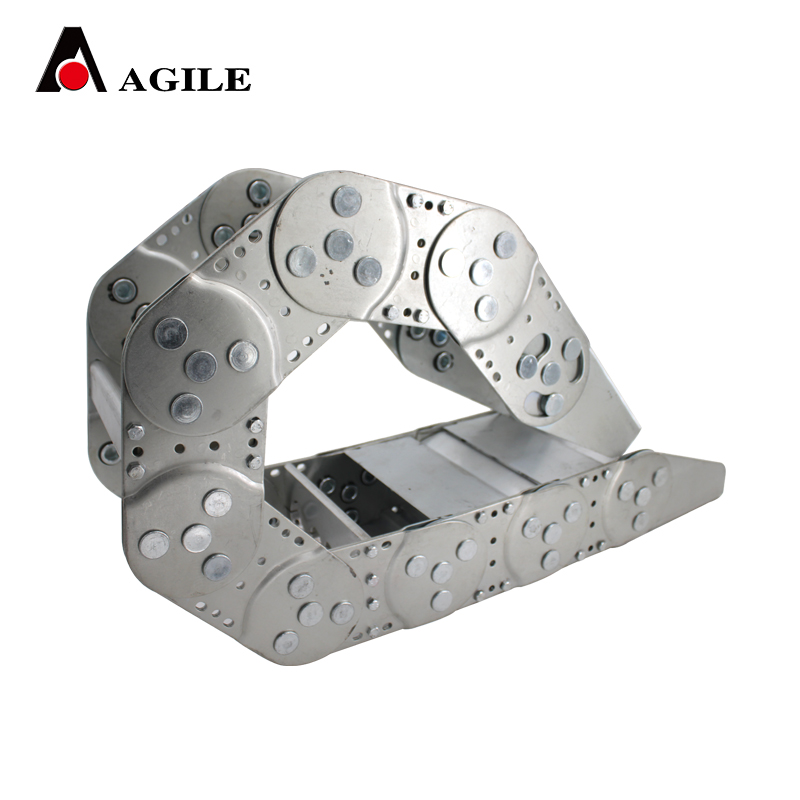

1. Drag Chain Conveyors This type uses a chain with cross bars or paddles that drag the chips along a track. It is effective for heavy loads and can handle large chips, making it a popular choice in heavy machining environments.

2. Auger Chip Conveyors Utilizing a screw-like mechanism, auger conveyors are particularly suited for transporting small chips and fines. They are often compact and can fit into spaces where traditional conveyors might not, making them versatile in various setups.

3. Magnetic Chip Conveyors These conveyors utilize magnets to transport ferrous metal chips. They are invaluable in operations where metal chips must be moved without the use of traditional mechanical means, which can lead to contamination.

4. Belt Conveyors Often used for light to moderate chip loads, belt conveyors are equipped with a continuous belt that moves the chips to a designated area. They are simple in design and can be customized with different belt materials to suit specific chip types.

what is a chip conveyor

5. Vibrating Chip Conveyors These conveyors employ vibrations to move chips along a trough. This design minimizes moving parts, making them low-maintenance and suitable for fine material transport.

Importance of Chip Conveyors

The importance of chip conveyors in the manufacturing process cannot be overstated. Here are several reasons why they are essential

1. Efficiency By automating the removal of chips, manufacturers can reduce downtime associated with manual cleaning and maintenance. This leads to an increase in machine availability and overall productivity.

2. Safety Accumulated chips and swarf can create hazards, such as slips and trips, and may even lead to machine damage. Chip conveyors minimize this risk by keeping the workspace clean and organized.

3. Sustainability Many chip conveyors are designed to facilitate the recycling of metal chips. By collecting and transporting chips effectively, manufacturers can reclaim raw materials, thus contributing to environmental sustainability efforts.

4. Improved Quality By removing chips promptly, chip conveyors help maintain the integrity of the machining operation. Chips left in the machining area can lead to defects in the workpiece due to re-cutting or smearing.

5. Cost-Effective Though there is an initial investment associated with chip conveyor systems, the long-term savings in labor costs, material recovery, and reduced machinery wear and tear can offset these expenses.

Conclusion

Chip conveyors are vital components in modern manufacturing, ensuring that machining operations run smoothly and efficiently. With various types available to meet diverse needs, manufacturers can choose the suitable conveyor system that enhances productivity while promoting worker safety and environmental sustainability. In today's fast-paced industrial landscape, investing in effective chip management solutions like chip conveyors is a step towards maximizing operational efficiency and maintaining competitiveness.