way covers and bellows

Understanding Way Covers and Bellows Essential Components in Machinery Protection

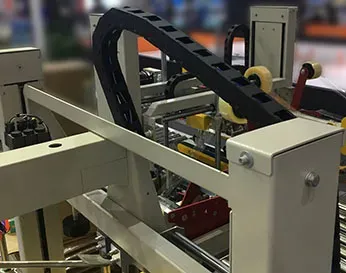

In the world of machinery and equipment operation, the preservation and protection of moving parts are paramount for efficiency and longevity. Two crucial components that play a significant role in this arena are way covers and bellows. These protective features serve to safeguard precision machinery from contaminants such as dust, dirt, and moisture, which can lead to wear and tear over time.

Way covers, also known as way shields, are typically made from sturdy materials, often plastics or metals. Their primary function is to shield the moving parts of machines, specifically the linear guideways and ball screws, from harmful debris. In various industrial settings, machines are constantly exposed to elements that can disrupt their functionality. Way covers ensure that the intricate mechanisms of the machinery remain clear of particulate matter, maintaining accuracy and performance. They can be implemented in a range of equipment, including CNC machines, lathes, and milling machines.

Bellows, on the other hand, are flexible protective covers designed to accommodate the inherent movements of machinery while providing a barrier against contaminants. The material used for bellows is usually a reinforced rubber or fabric, which allows for compressibility and expansion. This characteristic is crucial as it enables bellows to adapt to the precise movements of machinery components without compromising their protective function. Bellows are commonly found in applications where space is limited or where parts need to move in and out frequently, such as in robotic arms and various automated systems.

way covers and bellows

Both way covers and bellows are instrumental in prolonging the lifespan of machinery. By preventing the ingress of debris and liquids, these parts help reduce maintenance costs and downtime, ultimately enhancing productivity. Regular inspection and maintenance of these components are essential for ensuring they remain effective over time. Any signs of wear or damage should be addressed promptly to avoid compromising machinery efficiency.

Moreover, the design and installation of way covers and bellows can vary significantly based on the application's specific needs. Manufacturers often provide customizable options to cater to unique machinery requirements, allowing for optimal protection in diverse environments.

In conclusion, way covers and bellows are critical components in the realm of machinery protection. Their ability to safeguard essential moving parts from contamination plays a vital role in ensuring operational efficiency and maintaining the integrity of industrial equipment. As technology advances, the materials and designs used for these protective elements continue to evolve, further enhancing their effectiveness in various applications.