way covers and bellows

Understanding Way Covers and Bellows Essential Components in Machinery

In the world of machinery and mechanical systems, certain components play a crucial role in ensuring the longevity and efficiency of machines. Among these components, way covers and bellows stand out for their essential functions in protection and maintenance. This article delves into the significance of way covers and bellows, their types, and their applications in various industries.

What are Way Covers?

Way covers, also known as way protection covers, are protective devices that shield the moving parts of machines, particularly the sliding surfaces known as ways. These covers are designed to prevent dust, dirt, chips, and other contaminants from infiltrating the internal mechanisms of machines like CNC (Computer Numerical Control) mills, lathes, and grinding machines. The primary purpose of way covers is to maintain the precision of the machine's movement and prolong its operational life by reducing wear and tear.

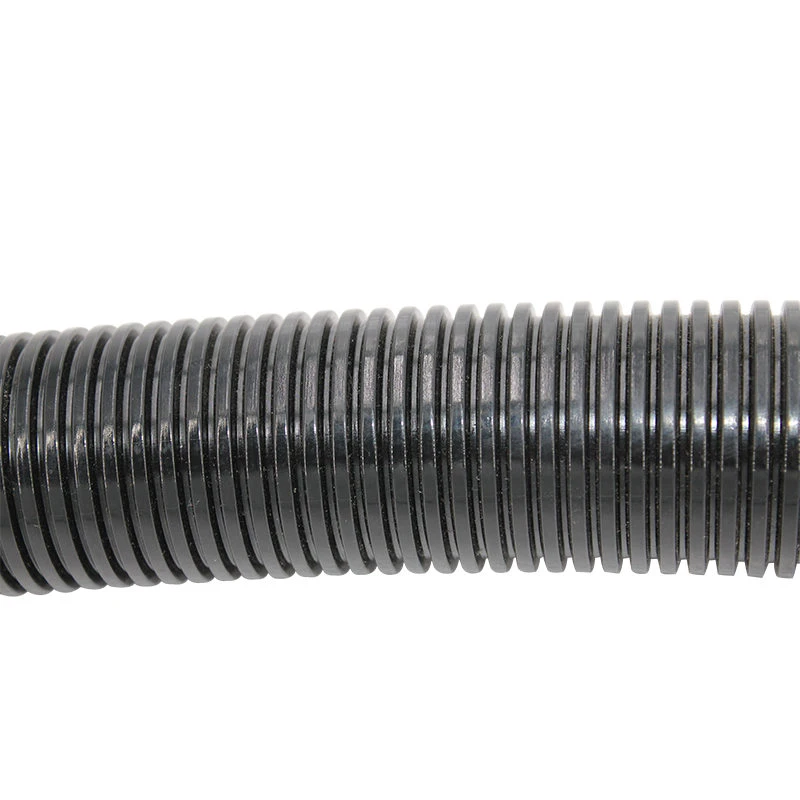

Way covers come in various designs, including accordion-style, bellows-type, and flat plate formats. The choice of design often depends on the specific application and the movement patterns of the machine's components. For instance, accordion-style covers are ideal for systems that require dynamic movement in multiple directions, whereas flat plate covers may be suitable for applications with limited movement.

What are Bellows?

Bellows are flexible, expandable containers typically made from rubber, plastic, or metal, designed to protect moving parts from contaminants. Similar to way covers, bellows help to seal and shield the sensitive areas of machinery, particularly in environments exposed to harsh conditions. They are used in applications where motion is required, allowing for expansion and contraction without compromising the integrity of the seal.

way covers and bellows

Bellows are crucial in systems where deterred movement could lead to mechanical failures. For instance, in hydraulic and pneumatic systems, bellows prevent fluid leaks and keep the internal components clean. They also play a vital role in maintaining vacuum conditions in vacuum systems.

Applications in Various Industries

Both way covers and bellows are widely utilized across various industries, including manufacturing, automotive, aerospace, and medical fields. In manufacturing, they are pivotal in protecting CNC machines, ensuring that components remain clean and precise, ultimately contributing to higher quality output. In the automotive industry, bellows are often utilized in exhaust systems to absorb vibrations and accommodate motion, preventing damage to sensitive components.

In aerospace applications, the importance of these protective components becomes even more pronounced. Here, way covers and bellows must withstand extreme conditions such as high temperatures, pressure variations, and exposure to fuel and chemicals. Their reliability is paramount in ensuring the safety and efficacy of various aircraft systems.

Conclusion

In conclusion, way covers and bellows are vital components in the realm of machinery, offering protection against contaminants while enhancing the precision and longevity of the systems they serve. With their diverse applications across industries, investing in quality way covers and bellows is essential for the maintenance and efficient operation of equipment. As technology continues to advance, the designs and materials used for these protective components will likely evolve, further enhancing their effectiveness and operational capabilities. Understanding their value not only aids in better maintenance practices but also ensures that industries can fully leverage the capabilities of their machinery.