way covers and bellows

The Importance of Way Covers and Bellows in Machinery Protection

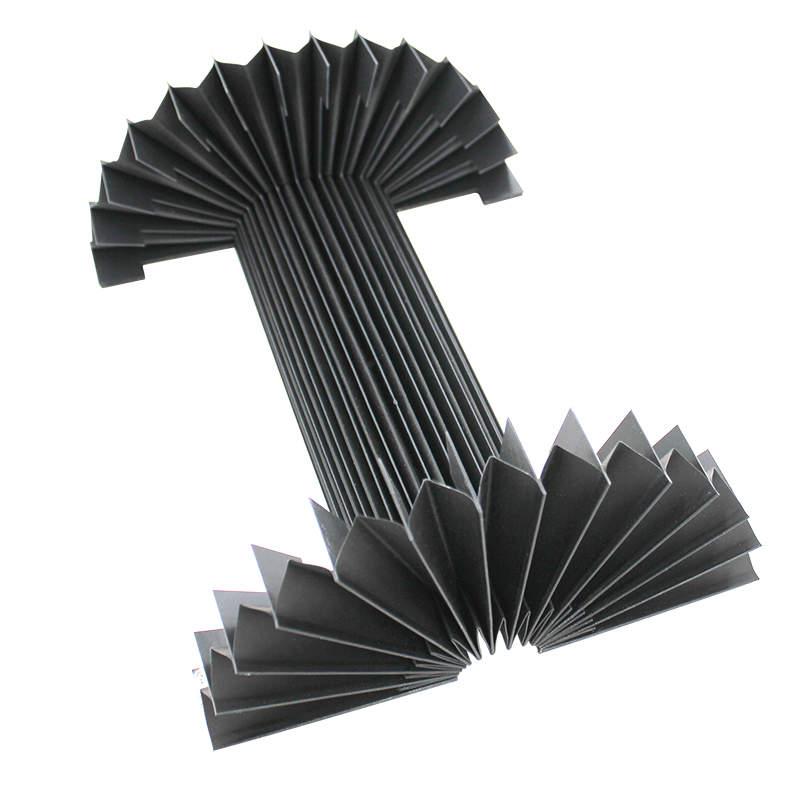

In the realm of machinery and engineering, the significance of protective components cannot be overstated. Among these, way covers and bellows play a crucial role in safeguarding essential machine parts from debris, cooling fluids, and other contaminants. By offering a layer of protection, these components not only enhance the longevity of machinery but also ensure optimal performance and efficiency.

Way covers are integral to many types of machinery, particularly in CNC machines and industrial equipment. These covers shield the exposed ways, which are the linear surfaces that guide the movement of machine components. Without way covers, these surfaces would be vulnerable to wear and damage caused by dust, metal shavings, and other particulates generated during machining processes. Over time, the wear on these surfaces can lead to misalignment, reduced accuracy, and costly repairs, ultimately affecting productivity and operational costs.

Bellows, on the other hand, serve a similar protective purpose but are often used for linear and rotary motion applications. Made from flexible materials, bellows can expand and contract, accommodating the movement of machine parts while maintaining a sealed environment. This is particularly important in areas where lubrication or hydraulic fluids are used, as bellows prevent contaminants from entering critical areas. By keeping these areas clean, bellows help maintain the integrity and reliability of machinery, ensuring that systems operate smoothly and with minimal downtime.

way covers and bellows

The design and material selection for way covers and bellows are critical for their effectiveness

. Manufacturers often rely on durable materials such as rubber, polyurethane, or stainless steel, which offer resistance to wear, chemicals, and temperature fluctuations. Additionally, the design must account for the specific range of motion and dimensions of the machinery to ensure proper fit and function.Regular maintenance of way covers and bellows is vital to their performance. Inspections should be conducted to check for signs of wear or damage, such as tears, cracks, or dislocation. Promptly addressing any issues can prevent more significant problems in the long run, protecting investments in machinery and minimizing operational disruptions.

In conclusion, way covers and bellows are essential components for protecting machinery from harmful contaminants and wear. Their role in maintaining the integrity of machine parts cannot be overlooked, as they contribute significantly to the reliability, efficiency, and longevity of industrial equipment. By investing in high-quality protective solutions and implementing a regular maintenance schedule, manufacturers can enhance their operational performance and reduce costs associated with repairs and downtime. Thus, understanding and prioritizing the use of way covers and bellows should be a fundamental practice for anyone involved in the maintenance and operation of machinery.