Understanding the Importance and Functionality of Synchronous V Belts in Mechanical Systems

Understanding Synchronous V Belts An Essential Component in Power Transmission

Synchronous V belts, often simply referred to as timing belts, are a crucial component in a wide range of mechanical systems. These belts are designed to ensure that the rotation of a drive pulley is precisely synchronized with the rotation of a driven pulley. This synchronization is critical in applications where timing is essential, such as in automotive engines and various manufacturing processes.

Structure and Design

Synchronous V belts are constructed with toothed profiles along their inner surface, which engage with corresponding teeth on the pulleys. This unique design allows for a positive engagement between the belt and the pulleys, preventing slippage and ensuring that the drive and driven components maintain a consistent rotational speed. The absence of slippage ensures enhanced efficiency and accuracy, making synchronous V belts the preferred choice in many applications.

These belts are typically made from high-strength materials such as rubber, polyurethane, or nylon, which provide flexibility and durability. The teeth of the belt, usually shaped in a trapezoidal pattern, are designed to reduce the risk of wear and tear, facilitating a longer lifespan compared to traditional V belts.

Applications

Synchronous V belts play a vital role in a variety of industries. In the automotive sector, they are commonly found in engine systems, controlling the timing of camshafts and crankshafts. This function is crucial for maintaining the proper timing of the engine's intake and exhaust valves, directly influencing performance and efficiency.

In manufacturing, synchronous V belts are used in conveyor systems, robotics, and machinery where precise timing is necessary for the operation. They are often found in applications like 3D printers, CNC machines, and assembly lines, where the smooth and synchronized movement of components is essential for productivity.

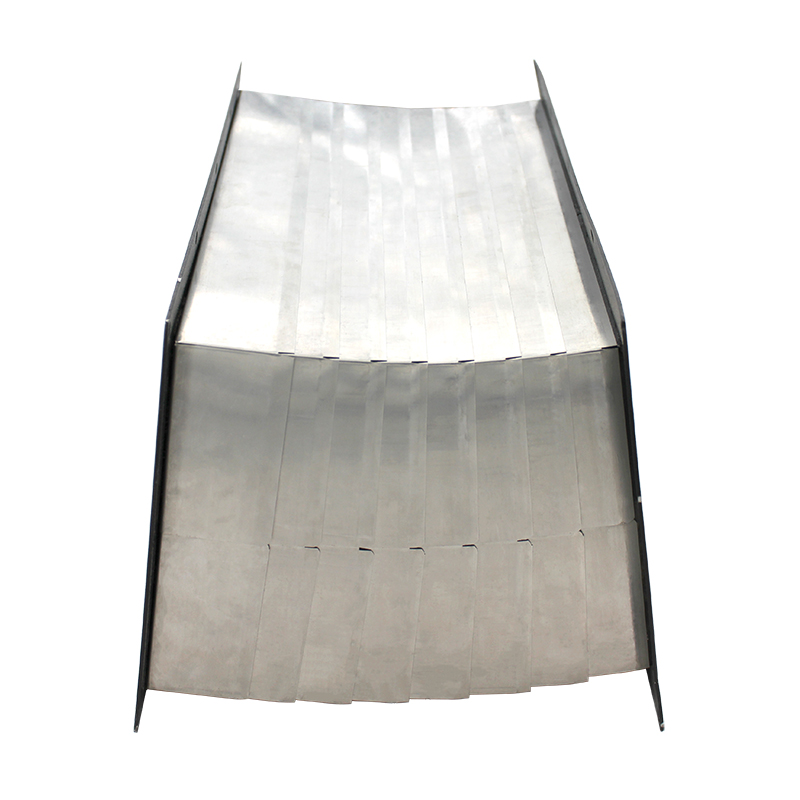

synchronous v belt

Advantages

One of the primary advantages of synchronous V belts is their high level of efficiency. Due to their design, they can transmit power with minimal losses, making them more efficient than traditional belts. Additionally, the absence of slippage ensures that the energy used in driving the system is effectively transferred, resulting in lower energy consumption.

Another benefit is their relatively low maintenance requirements. Unlike chain drives or traditional V belts that may require regular tension adjustments, synchronous V belts operate within a set tension range, reducing the need for frequent monitoring and adjustment. This characteristic not only saves time but also decreases the likelihood of unexpected breakdowns and increases overall reliability.

Limitations and Considerations

Despite their numerous benefits, synchronous V belts do have some limitations. One notable drawback is that they are sensitive to misalignment. If the pulleys are not properly aligned, it can lead to accelerated wear and potential failure of the belt. Therefore, ensuring correct installation and alignment is crucial for optimal performance.

Moreover, extreme operating conditions—such as high temperatures or harsh chemicals—can affect the material integrity and performance of synchronous V belts. Selecting the right type of belt for specific operating environments is essential to avoid premature failure.

Conclusion

Synchronous V belts are a remarkable innovation in the realm of power transmission, offering precise timing, high efficiency, and low maintenance requirements. Their importance in various industries cannot be overstated, as they contribute significantly to the functionality of numerous mechanical systems. When selecting a synchronous V belt, it is essential to consider the application's specific requirements and operating conditions to ensure optimal performance and longevity. With the right choice, synchronous V belts can pave the way for enhanced productivity and efficiency in machinery and automotive applications alike.