Understanding the Benefits and Uses of 3% Split Loom Tubing for Cable Management Solutions

Understanding the Benefits of 3% 208% Split Loom Tubing A Comprehensive Guide

In the world of wiring and electrical systems, ensuring optimal protection and organization of cables is paramount. One of the most effective solutions available in the market is the split loom tubing, specifically the 3% 208% variant. This tubing offers numerous advantages for both professional electricians and DIY enthusiasts alike.

What is Split Loom Tubing?

Split loom tubing is a type of protective covering for wires and cables. Its design features a slit along the length of the tubing, allowing for easy insertion and removal of wires while providing a snug fit. The 3% 208% designation refers to specific characteristics of the tubing—this includes its diameter, material composition, flexibility, and resistance to various environmental factors.

Benefits of Using 3% 208% Split Loom Tubing

1. Enhanced Protection One of the primary functions of split loom tubing is to protect electrical wires from physical damage, abrasion, and external environmental factors. The 3% 208% split loom tubing is constructed from high-quality materials that resist cuts, tears, and impacts, ensuring that the wires it encases remain intact and undamaged over time.

2. Heat Resistance In many electrical applications, wires can heat up, which can lead to potential failure or hazards. The 3% 208% split loom tubing is designed to withstand elevated temperatures, making it suitable for use in automotive, industrial, and household applications. This property helps in preventing fires and other heat-related issues.

3. Organization and Clean Appearance A well-organized wiring system is critical for both functionality and aesthetics. Using split loom tubing helps bundle multiple wires together, reducing clutter and providing a cleaner look. This is especially beneficial in professional settings or custom installations where presentation is crucial.

3 8 split loom tubing

4. Flexibility and Ease of Installation The split nature of the loom allows for easy installation and removal of wires as needed. This feature is particularly useful for installations that may require modifications or repairs over time. Additionally, the 3% 208% variant is designed to be highly flexible, allowing it to easily navigate tight spaces and complex layouts.

5. Electrical Insulation Split loom tubing provides a degree of electrical insulation, which can be particularly important in preventing accidental short circuits. While it should not be considered a substitute for primary insulation on wires, it adds an additional layer of safety, especially in environments with a high risk of wire exposure.

6. Resistance to Chemicals and UV Rays The 3% 208% split loom tubing also offers resistance to various chemicals and ultraviolet rays, ensuring longevity and durability even in harsh conditions. This makes it a viable choice for outdoor applications where exposure to sunlight and other environmental stresses is a concern.

Applications of 3% 208% Split Loom Tubing

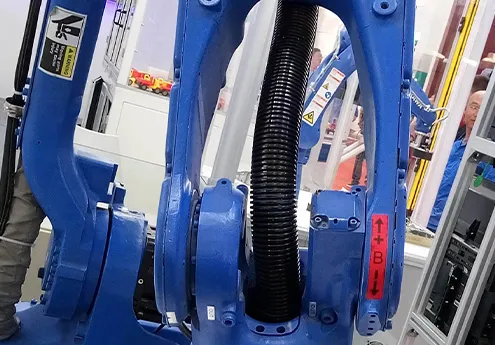

Due to its many advantages, the 3% 208% split loom tubing is widely used across various industries. From automotive wiring harnesses and electrical installations in homes to industrial machinery and robotics, its versatility makes it a favored choice among professionals.

Conclusion

In summary, the 3% 208% split loom tubing is a robust and practical solution for protecting and organizing wires in numerous applications. Its combination of durability, flexibility, and insulation properties make it an invaluable resource in both residential and industrial settings. As technology continues to evolve, the importance of effective wiring management and protection only becomes more pronounced, reinforcing the role of split loom tubing in modern electrical systems. Whether you are a seasoned electrician or a DIY hobbyist, integrating 3% 208% split loom tubing into your projects can enhance safety, functionality, and aesthetics.