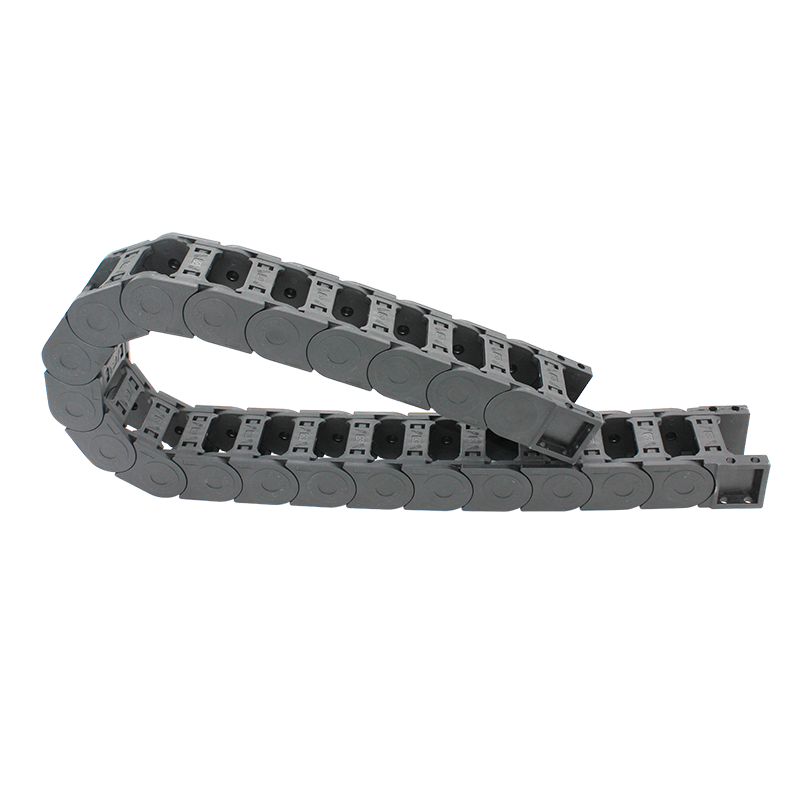

turbo systems chip conveyor

Turbo Systems Chip Conveyor Enhancing Efficiency in Manufacturing

In today's fast-paced manufacturing environment, efficiency and precision are paramount. One of the key components that play a crucial role in this landscape is the chip conveyor system. Among the various options available, Turbo Systems has emerged as a frontrunner in delivering innovative solutions that significantly enhance productivity while maintaining the highest standards of quality.

Turbo Systems Chip Conveyor Enhancing Efficiency in Manufacturing

One of the standout features of Turbo Systems’ chip conveyors is their versatility. These conveyors are compatible with a wide range of materials, making them suitable for various machining applications, including metalworking, woodworking, and plastic processing. This adaptability allows manufacturers to utilize Turbo’s systems across multiple departments without the need for significant modifications or bespoke solutions.

turbo systems chip conveyor

Another significant advantage of Turbo Systems chip conveyors is their robust design, which ensures durability and longevity. Constructed from high-quality materials, these conveyors can withstand the rigors of demanding environments and the wear and tear associated with continuous usage. This reliability translates to less frequent maintenance requirements, further enhancing the overall efficiency of manufacturing operations.

Moreover, Turbo Systems prioritizes the implementation of advanced technology in their chip conveyors. The incorporation of smart sensors and automation allows for real-time monitoring of the conveyor system’s performance. This data-driven approach enables manufacturers to make informed decisions, optimize processes, and predict maintenance needs before issues arise. As a result, production lines can run more smoothly, minimizing disruptions and maximizing output.

Eco-friendliness is another critical aspect of contemporary manufacturing practices, and Turbo Systems' chip conveyors are designed with sustainability in mind. By efficiently managing waste, these systems reduce the environmental impact associated with machining operations. The reduced need for manual labor not only lowers operational costs but also contributes to a safer working environment.

In conclusion, Turbo Systems chip conveyor solutions represent a significant step forward in manufacturing efficiency. By integrating technology, durability, and versatility, these conveyors not only simplify chip removal processes but also enhance overall productivity. As the manufacturing industry continues to evolve, investing in advanced solutions like Turbo Systems will be crucial for businesses aiming to stay competitive in an ever-changing landscape. With a focus on innovation and sustainability, Turbo Systems is well-positioned to support manufacturers in achieving their operational goals while promoting a more efficient and environmentally responsible future.