turbo chip conveyor

Turbo chip conveyors have revolutionized the way we handle machining waste, providing an efficient and seamless solution for the removal and management of metal chips. Designed for high-volume production environments, these conveyors are indispensable for any operation aiming to maintain productivity and ensure safety.

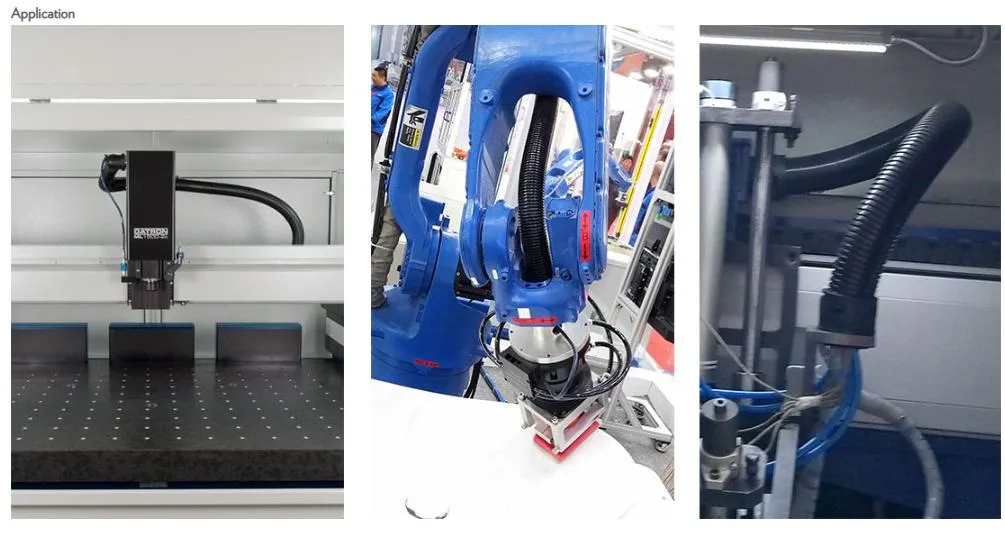

The authority of turbo chip conveyors does not solely rest on their mechanical reliability but also on their role in enhancing workplace safety and efficiency. By automating chip removal, these conveyors lessen the physical labor required from human operators, minimizing the risk of injury. Moreover, they contribute to a cleaner work environment which is crucial for maintaining safety standards and optimizing machine efficiency. Trustworthiness in the technology of turbo chip conveyors is established through numerous successful implementations across various industries. From automotive to aerospace, companies have reported significant improvements in their machining operations, as these conveyors have proven to reliably handle high volumes of chips without faltering. Each installation is often accompanied by comprehensive support and service, underscoring the manufacturers' commitment to quality and customer satisfaction. For businesses considering the adoption of turbo chip conveyors, the potential returns on investment are significant. Reduced machine downtime, lower maintenance costs, and enhanced safety all contribute to not only immediate operational improvements but also long-term financial benefits. By opting for a turbo chip conveyor system, companies can ensure that their machining operations remain competitive and productive in a demanding marketplace. As the landscape of manufacturing continues to evolve, the adoption of turbo chip conveyors positions companies at the forefront of innovation. These systems embody the perfect synergy of experience, expertise, authoritativeness, and trustworthiness. By integrating this technology, businesses not only address the immediate challenge of chip management but also set a foundation for sustainable operational success.

The authority of turbo chip conveyors does not solely rest on their mechanical reliability but also on their role in enhancing workplace safety and efficiency. By automating chip removal, these conveyors lessen the physical labor required from human operators, minimizing the risk of injury. Moreover, they contribute to a cleaner work environment which is crucial for maintaining safety standards and optimizing machine efficiency. Trustworthiness in the technology of turbo chip conveyors is established through numerous successful implementations across various industries. From automotive to aerospace, companies have reported significant improvements in their machining operations, as these conveyors have proven to reliably handle high volumes of chips without faltering. Each installation is often accompanied by comprehensive support and service, underscoring the manufacturers' commitment to quality and customer satisfaction. For businesses considering the adoption of turbo chip conveyors, the potential returns on investment are significant. Reduced machine downtime, lower maintenance costs, and enhanced safety all contribute to not only immediate operational improvements but also long-term financial benefits. By opting for a turbo chip conveyor system, companies can ensure that their machining operations remain competitive and productive in a demanding marketplace. As the landscape of manufacturing continues to evolve, the adoption of turbo chip conveyors positions companies at the forefront of innovation. These systems embody the perfect synergy of experience, expertise, authoritativeness, and trustworthiness. By integrating this technology, businesses not only address the immediate challenge of chip management but also set a foundation for sustainable operational success.