The Essential Guide to Bellows Covers: Protecting Machinery and Ensuring Longevity

Bellows covers, including machine bellows covers, bellows for ball screw, and bellow dust covers, are crucial components in safeguarding machinery and extending its operational lifespan. These protective elements help shield sensitive parts from dust, debris, and other environmental factors. Here’s an in-depth look at their applications, benefits, and proper use.

Understanding the Role of Bellows Covers

Bellows covers are designed to protect moving parts of machinery and equipment from contaminants and physical damage. Their primary functions include:

- Protection from Debris: Machine bellows coversshield critical components such as ball screws, linear guides, and shafts from dust, dirt, and other particles that can cause wear and tear.

- Prevention of Damage: By covering exposed parts, bellow dust coversprevent physical damage from impacts or accidental contact, ensuring the machinery operates smoothly and reliably.

- Extended Equipment Lifespan: Properly installed bellows for ball screwand other types of covers help to extend the life of the machinery by reducing the risk of damage and minimizing maintenance needs.

Types of Bellows Covers and Their Applications

Each type of bellows cover is suited to specific applications and environmental conditions. Here’s a breakdown of the different types and their uses:

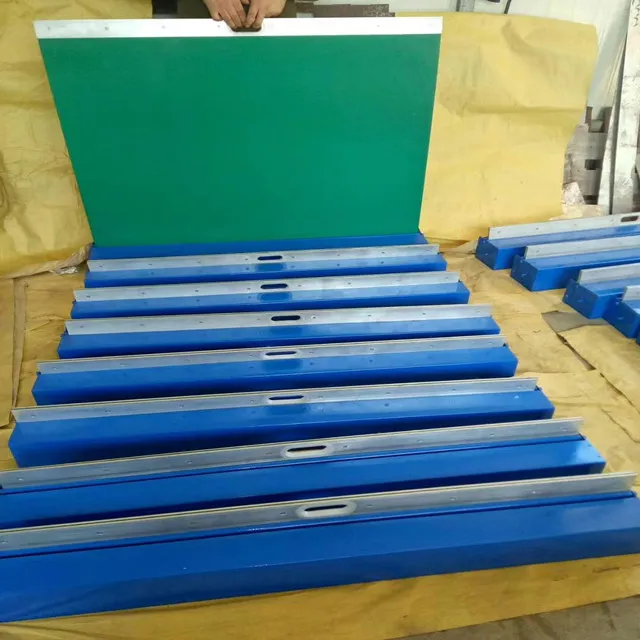

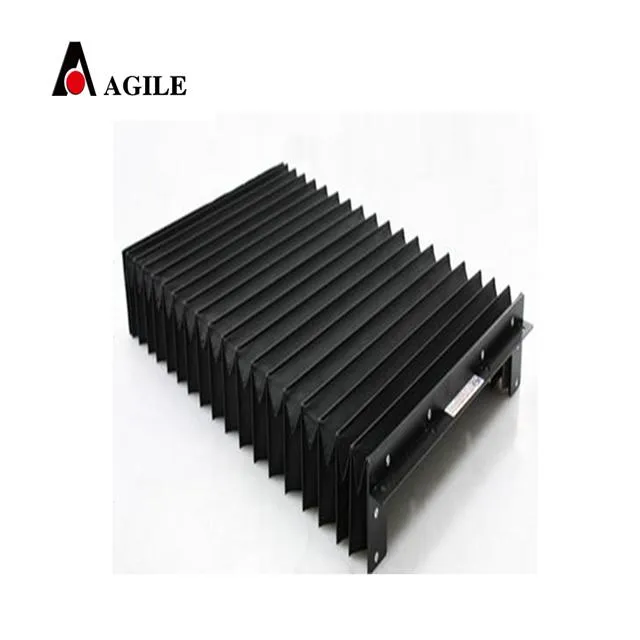

Machine Bellows Covers: These are versatile and commonly used to protect various machine components, such as guide rails, spindles, and tables. They are typically made from durable materials like rubber or fabric and are designed to accommodate a range of movements and sizes.

Bellows for Ball Screw: Specifically designed for ball screws, these bellows provide protection against dust and debris that can affect the screw’s performance and accuracy. They are often made from high-strength materials to withstand the mechanical stresses of the ball screw system.

Bellow Dust Covers: These covers are used in environments where dust and small particles are prevalent. They provide a barrier to prevent these contaminants from reaching sensitive parts of the machinery, thus reducing the risk of damage and wear.

Benefits of Using Bellows Covers

Bellows covers offer several benefits that contribute to the efficient and reliable operation of machinery:

Enhanced Protection: They offer effective protection against dust, debris, and physical impacts, which helps maintain the functionality and accuracy of machinery components.

Reduced Maintenance: By preventing contaminants from reaching critical parts, machine bellows covers reduce the need for frequent cleaning and maintenance, saving time and labor costs.

Improved Safety: Protecting moving parts with bellow dust covers reduces the risk of accidents and injuries caused by exposed components or debris.

Increased Equipment Lifespan: The protection provided by bellows for ball screw and other covers helps to extend the life of the equipment by minimizing wear and tear.

Choosing the Right Bellows Cover for Your Application

Selecting the appropriate bellows cover involves considering various factors to ensure optimal performance and protection:

Material: Choose a material that matches the environmental conditions and mechanical requirements of your application. Common materials include rubber, fabric, and metal, each offering different levels of durability and flexibility.

Size and Fit: Ensure that the cover is sized correctly for the component it will protect. A proper fit is crucial to ensure effective protection and avoid issues with movement or installation.

Type of Movement: Consider the type of movement involved in your application. For example, machine bellows covers should be able to accommodate the specific range and type of motion (linear, rotary, etc.) of the machinery.

Environmental Conditions: Assess the environmental factors such as temperature, moisture, and chemical exposure. Select a cover that can withstand these conditions and provide the necessary protection.

Proper Installation and Maintenance of Bellows Covers

To ensure the effectiveness of your bellows covers, follow these installation and maintenance tips:

Correct Installation: Install the cover according to the manufacturer’s instructions, ensuring a proper fit and secure attachment. Incorrect installation can reduce the effectiveness of the cover and lead to premature wear.

Regular Inspections: Periodically inspect the covers for signs of wear, damage, or contamination. Replace or repair any damaged sections to maintain protection and functionality.

Cleaning: Keep the covers clean and free from debris. Regular cleaning helps to ensure that the covers remain effective in protecting the machinery.

Adjustment and Replacement: Adjust or replace covers as needed based on wear or changes in the machinery. Proper maintenance ensures continued protection and efficiency.

Bellows covers, including machine bellows covers, bellows for ball screw, and bellow dust covers, are essential for protecting machinery components and extending equipment life. By understanding their applications, benefits, and proper use, you can ensure that your machinery remains in optimal condition and operates efficiently. Choose the right type of cover for your specific needs, and follow best practices for installation and maintenance to achieve the best results.