telescopic bellow cover

Understanding Telescopic Bellow Covers Functions, Applications, and Benefits

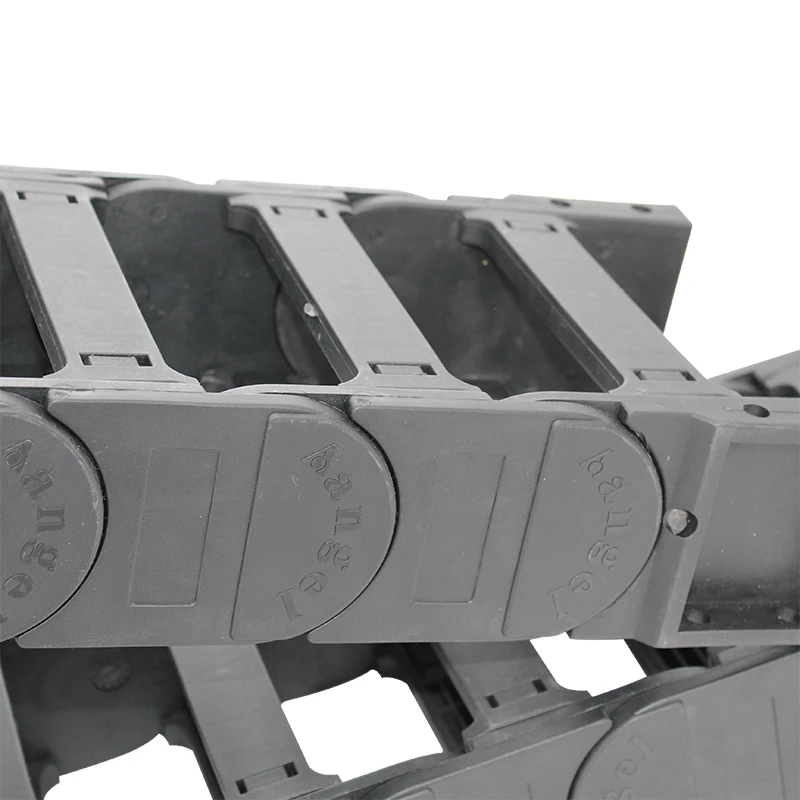

Telescopic bellow covers play a crucial role in various industrial applications, serving as protective devices designed to shield machinery and components from contaminants and external damage. With their unique structure and functionality, these covers are essential in enhancing the longevity and efficiency of equipment used in manufacturing, automation, and other sectors.

What Are Telescopic Bellow Covers?

Telescopic bellow covers are flexible, accordion-like protective casings made from materials such as polyurethane, rubber, or fabric. Their design allows them to extend and retract, accommodating the movement of machine parts, while simultaneously preserving the integrity of the equipment beneath. This feature makes them particularly useful for applications where components undergo significant travel or movement.

Functions of Telescopic Bellow Covers

1. Protection from Contaminants One of the primary functions of telescopic bellow covers is to protect sensitive machine parts from dust, dirt, water, and other contaminants that could impair performance. By creating a sealed environment, these covers prevent foreign materials from entering critical areas, thereby prolonging the life of machinery.

2. Minimizing Wear and Tear Due to constant movement in machinery, components can experience friction and wear over time. Telescopic bellow covers help to minimize this by providing a barrier that reduces direct contact between moving parts and external elements.

3. Safety In industrial settings, safety is paramount. Telescopic bellow covers can prevent operators from coming into contact with moving parts, thereby reducing the risk of injuries. They serve as a physical barrier, ensuring that the machinery operates safely.

4. Aesthetic Appeal Beyond their protective functions, telescopic bellow covers can also enhance the overall appearance of machinery. Available in various colors and styles, they can be tailored to meet the aesthetic requirements of different industries while still fulfilling their protective roles.

Applications of Telescopic Bellow Covers

Telescopic bellow covers find applications across a diverse range of industries, including

telescopic bellow cover

- Machine Tools In the world of machining, these covers protect CNC machines, lathes, and milling machines from chips and lubricants. By keeping the working area clean, they ensure precision and accuracy during manufacturing processes.

- Robotics In robotic applications, telescopic bellow covers are utilized to safeguard the joints and mechanisms that undergo continuous movement. They keep debris out of pivotal points, ensuring optimal performance and decreasing maintenance needs.

- Automotive Industry In automotive manufacturing, these covers protect assembly line robots and other equipment from harsh environments, such as oil and dirt exposure. This not only extends the machinery's life but also contributes to efficient production processes.

- Industrial Equipment Whether it’s conveyor systems, packaging machines, or assembly lines, telescopic bellow covers are vital. They ensure that operational equipment remains free from foreign elements, facilitating smooth and uninterrupted production.

Benefits of Telescopic Bellow Covers

1. Durability Constructed from robust materials, telescopic bellow covers are designed to withstand the rigors of industrial environments. Their resilience to wear and tear means they can provide long-term protection for machinery.

2. Cost-Effective Maintenance By protecting machinery from damage and contamination, telescopic bellow covers can significantly reduce maintenance costs. This not only saves money but also minimizes downtime associated with repairs and replacements.

3. Enhanced Performance By keeping critical components clean and free from contamination, telescopic bellow covers help maintain optimal performance levels. Machines run more efficiently, leading to improved productivity.

4. Customizability These covers can be tailored to fit specific machinery dimensions and operational needs. Custom designs ensure that equipment protection is maximized based on its unique operational environment.

Conclusion

In conclusion, telescopic bellow covers are more than just protective casings; they are integral components that enhance the functionality, safety, and longevity of industrial machinery. As industries continue to evolve and embrace automation, the importance of such protective solutions cannot be overstated. Understanding their functions, applications, and benefits can help businesses invest wisely in equipment care, ultimately leading to improved performance and reduced operational costs. By opting for high-quality telescopic bellow covers, companies can protect their investments and ensure sustained productivity in an increasingly competitive landscape.